Elastic ribbon machine

A technology of elastic machine and elastic belt, which is applied in the direction of cloth feeding mechanism, sewing machine components, manufacturing tools, etc., achieves the effect of improving loop forming speed, simple structure, and convenient sewing and fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

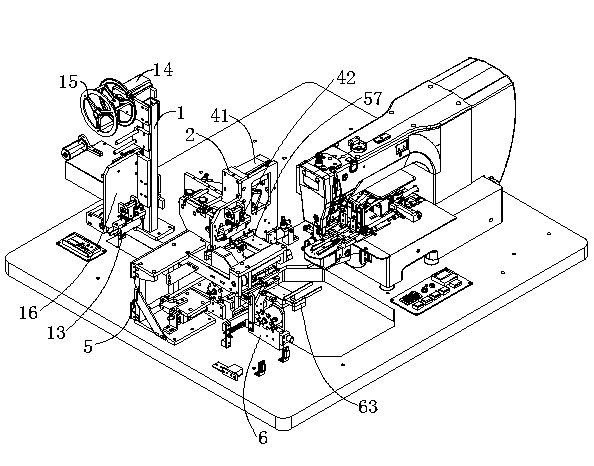

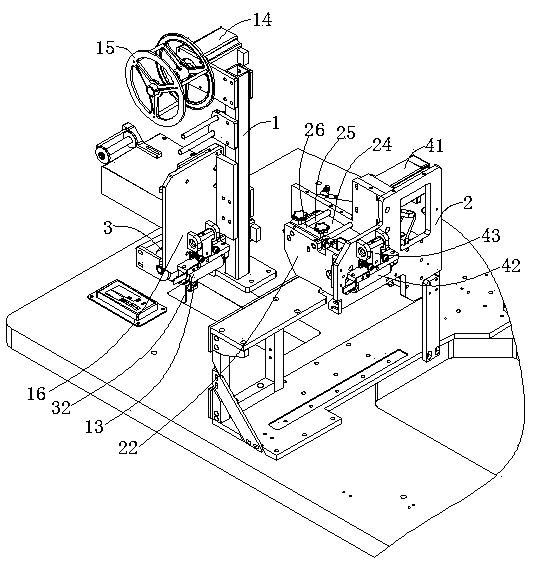

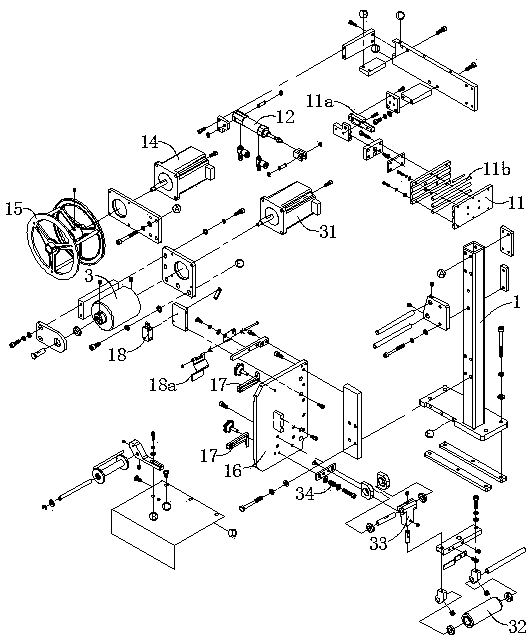

[0023] Figure 1 to Figure 7 Shown is the structural representation of the present invention.

[0024] Wherein the reference numerals are: first frame 1, heating plate 11, heating guide rail 11a, electric heating rod 11b, heating cylinder 12, material storage sensor 13, third motor 14, material handling roller 15, backing plate 16, Adjust the limit block 17, the joint sensor 18, the induction flap 18a, the second frame 2, the first installation substrate 21, the second installation substrate 22, the third installation substrate 23, the feeding pallet 24, the driven wheel shaft 25, Adjusting block 26, the first feeding driving wheel 3, the first motor 31, the first feeding driven wheel 32, the first driven wheel mounting bracket 33, the first spring 34, the second feeding driving wheel 4, the rotating drive shaft 4a, the second Motor 41, first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com