Sewing machine

A sewing machine and thread technology, which is applied to sewing machine components, sewing equipment, sewing machine control devices, etc., can solve the problems such as the inability of the presser foot to rise, become unbalanced, and the inability to lower the position of the presser foot, so as to avoid excessive burden, The effect of preventing dissonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

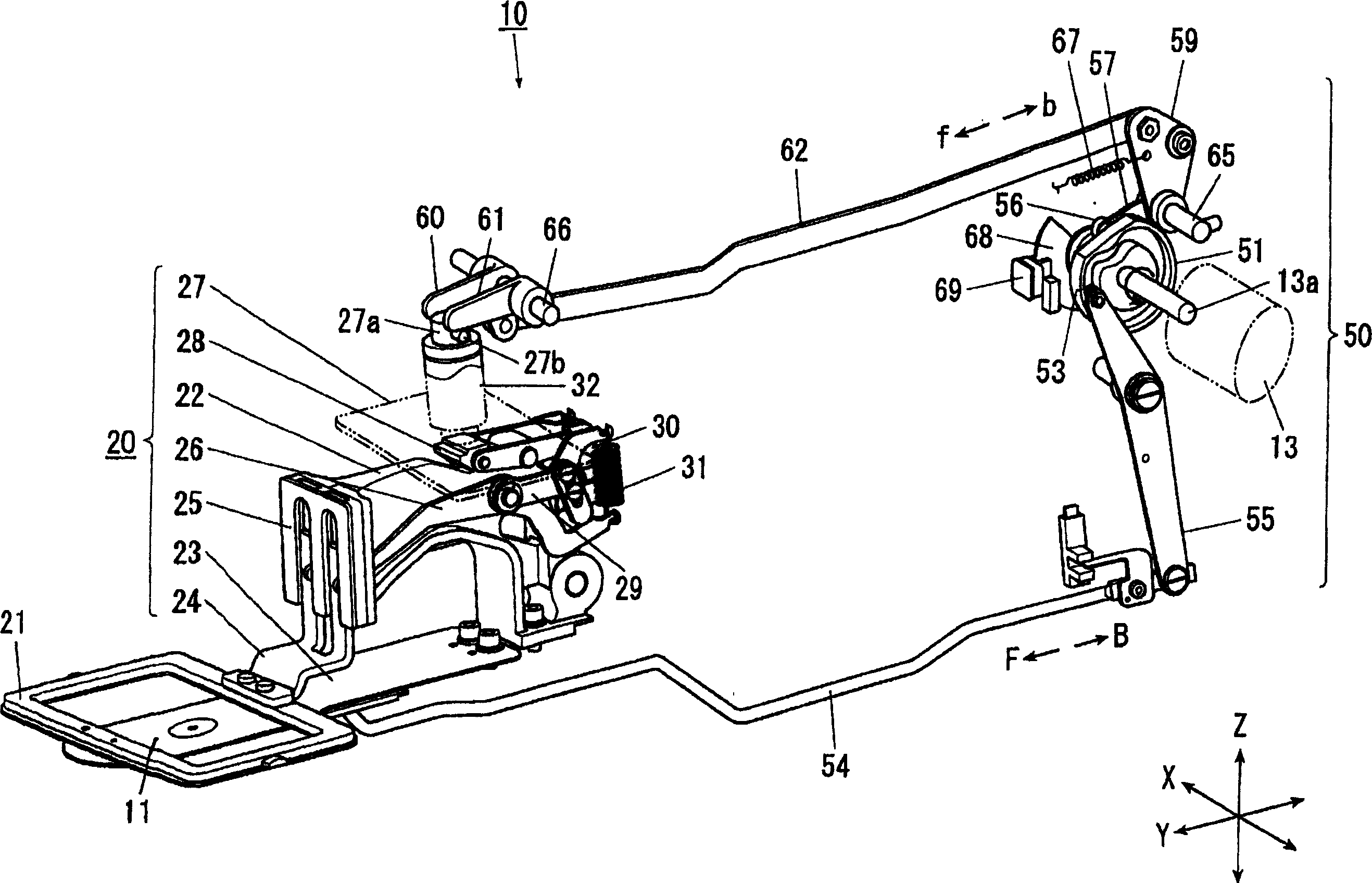

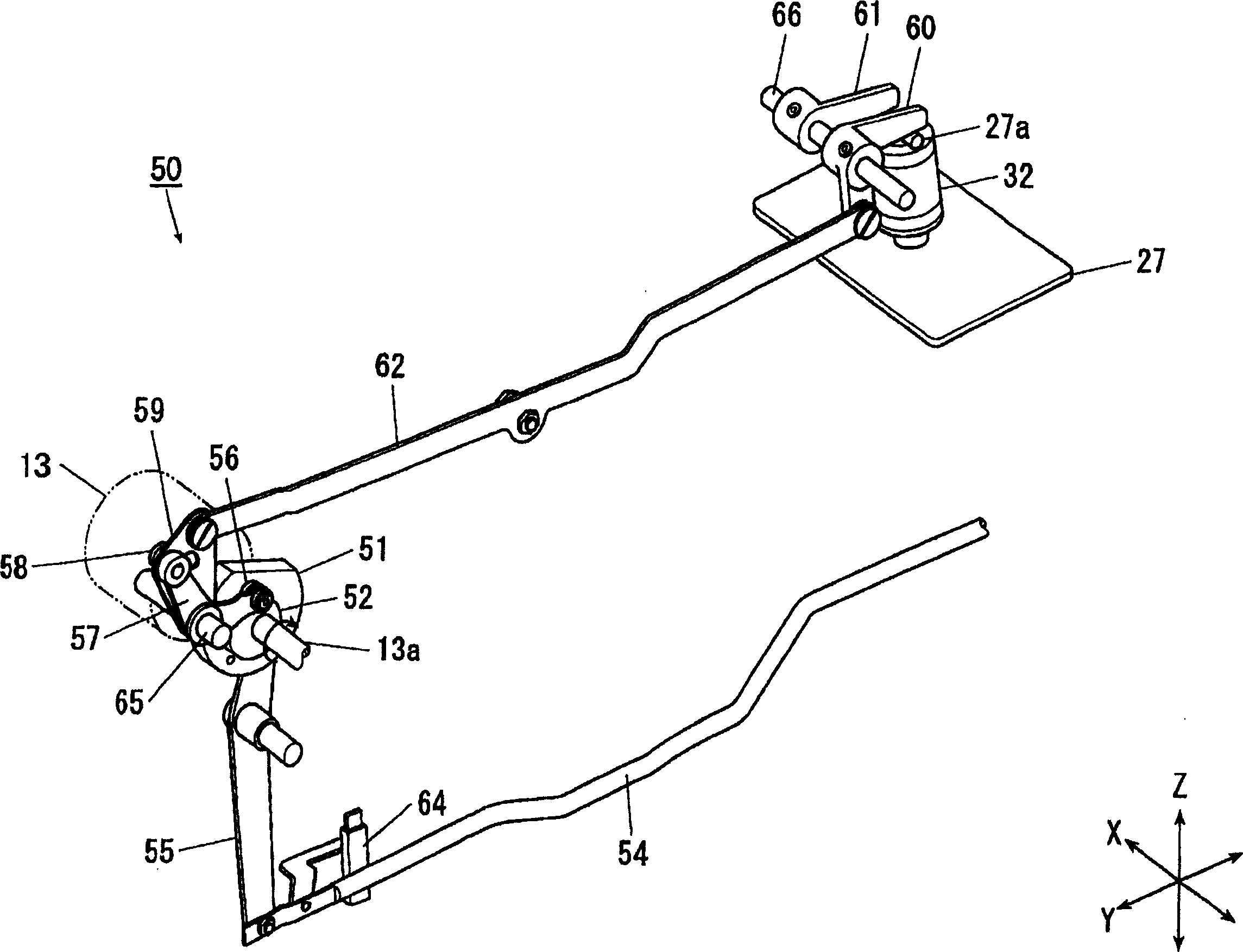

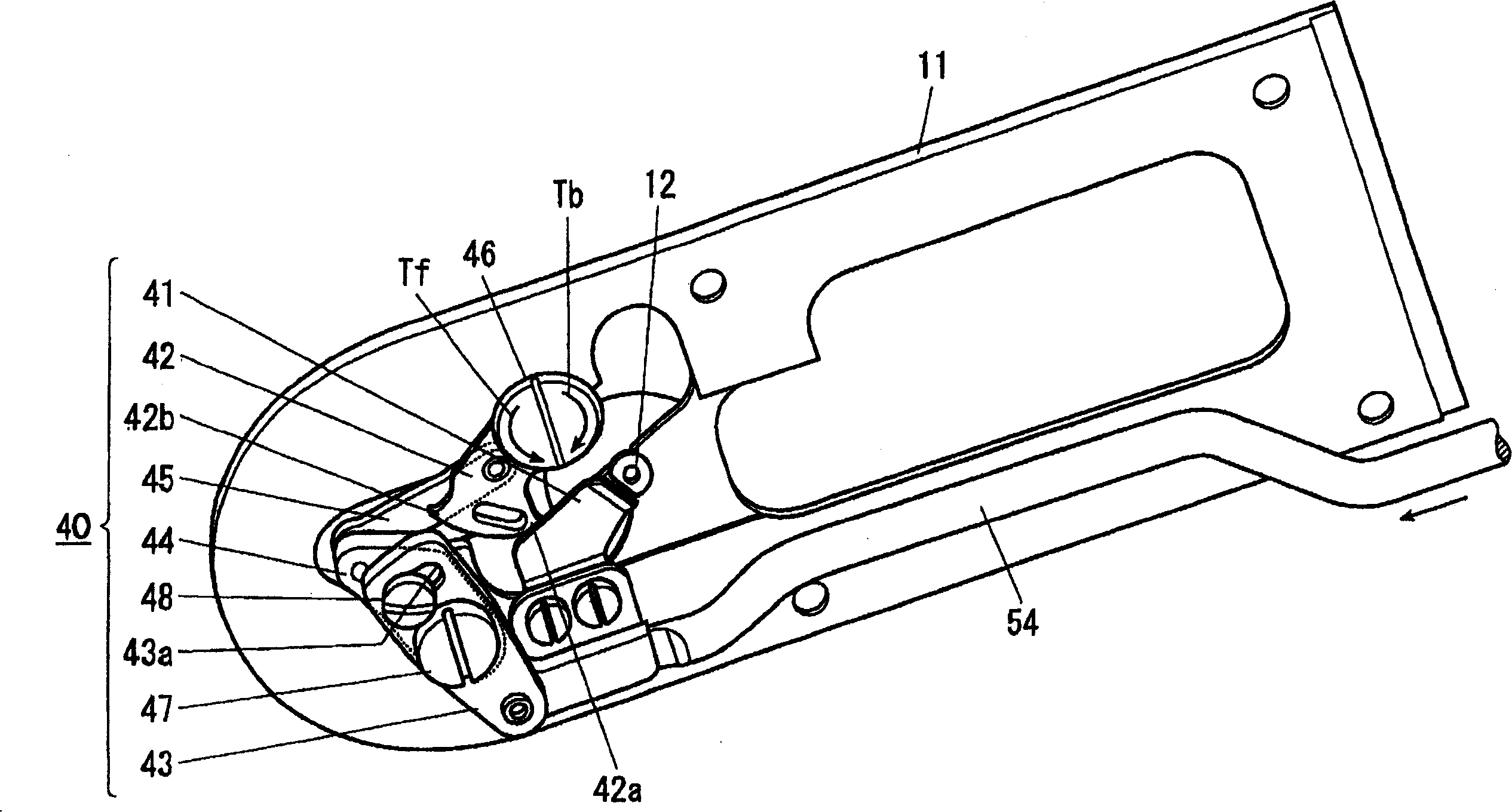

[0021] Below, according to Figure 1 to Figure 6 Examples of the present invention will be described in detail. FIG. 1 is a perspective view showing only the main configuration of a sewing machine 10 as an embodiment of the invention. figure 2 is from and figure 1 A perspective view of only the main components of the sewing machine 10 viewed from different directions.

[0022] The sewing machine 10 includes an unillustrated sewing machine housing for holding or accommodating various components. The vertical fuselage part, the nose part extending in the same direction from the upper end part of the vertical fuselage part and the bottom plate part. In the following description, in the state where the sewing machine 10 is placed on a horizontal plane, the direction parallel to the horizontal and longitudinal direction of the bottom plate portion is referred to as the Y-axis direction, and the direction horizontal and perpendicular to the Y-axis direction is referred to as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com