Watch spring winding apparatus

A technology of watches and automatic watches, applied in the direction of automatic winding, clocks, clockwork ratchet mechanisms, etc., can solve problems such as large spaces, and achieve the effect of improving transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

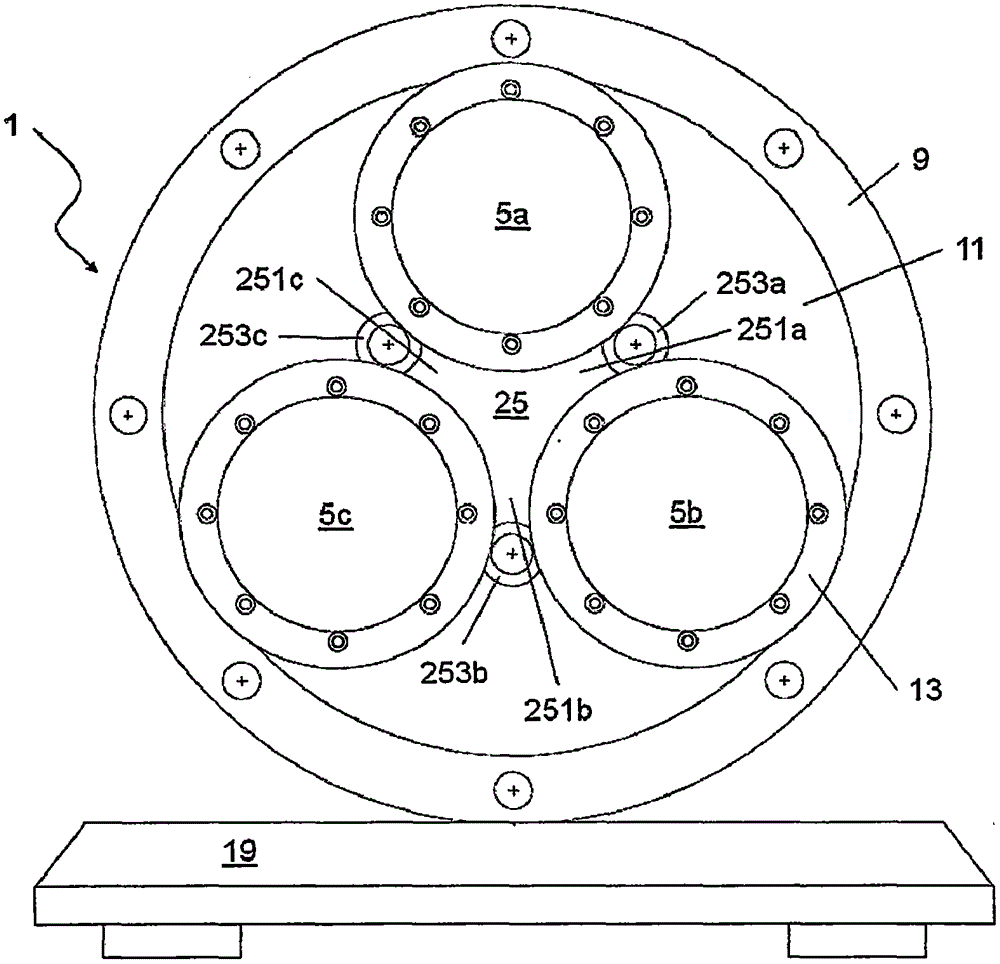

[0091] exist figure 1 In , a first embodiment of a first variant of the invention of a watch winding device 1 according to the invention is shown. The transmission element 25 is arranged centrally therein. Arranged around the transmission element are three receiving cylinders 5a, 5b, 5c, said receiving cylinders being in a corresponding position by their lateral surfaces with the transmission element 25, more precisely with the rotation elements 253a, 253b, 253c. Force locked contact. However, the receiving cylinders 5a, 5b, 5c are spaced at a distance from each other. This ensures that the rotational movement of the transmission element 25 converted into a relative rotational movement of the receiving cylinders 5a, 5b, 5c is not inhibited. The receiving cylinders 5a, 5b, 5c form an arrangement plane. By the rotational movement of the transmission element 25 , the receiving cylinders 5 a , 5 b , 5 c all rotate about their longitudinal axes and also move on a circular path ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com