Vacuum sucker

A technology of vacuum suction cups and cavities, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as suction cups losing their effect, calendar rings that cannot meet production requirements, and the task of picking and placing small-diameter circular watch parts. Replacement, strong practicability, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

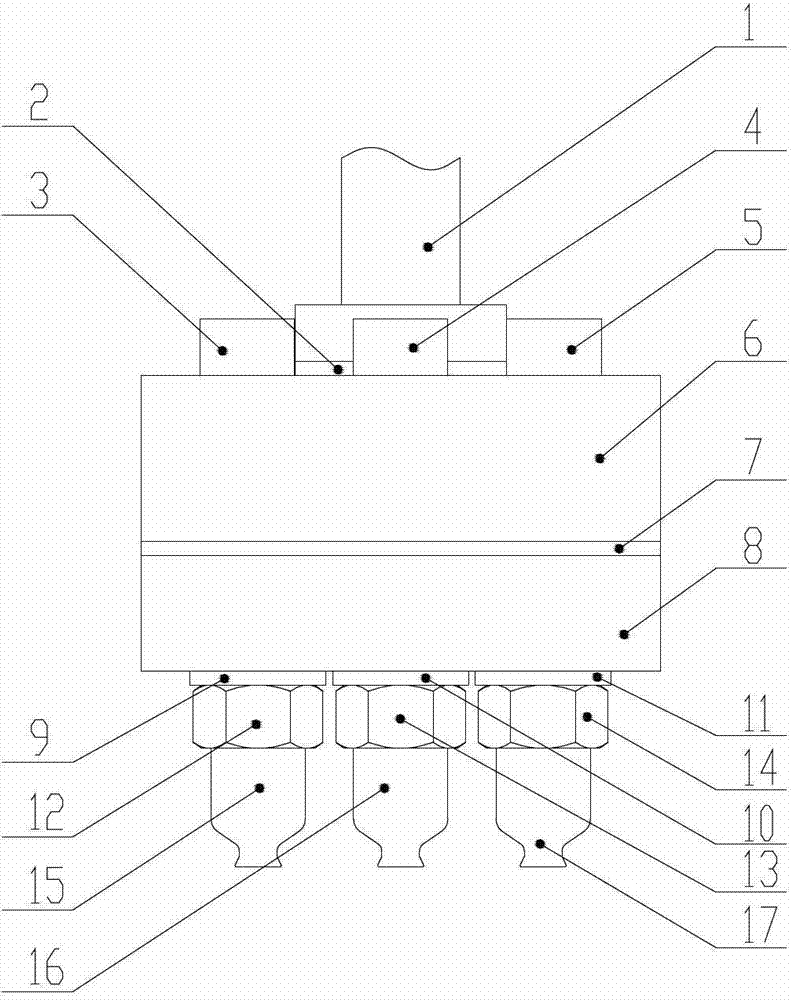

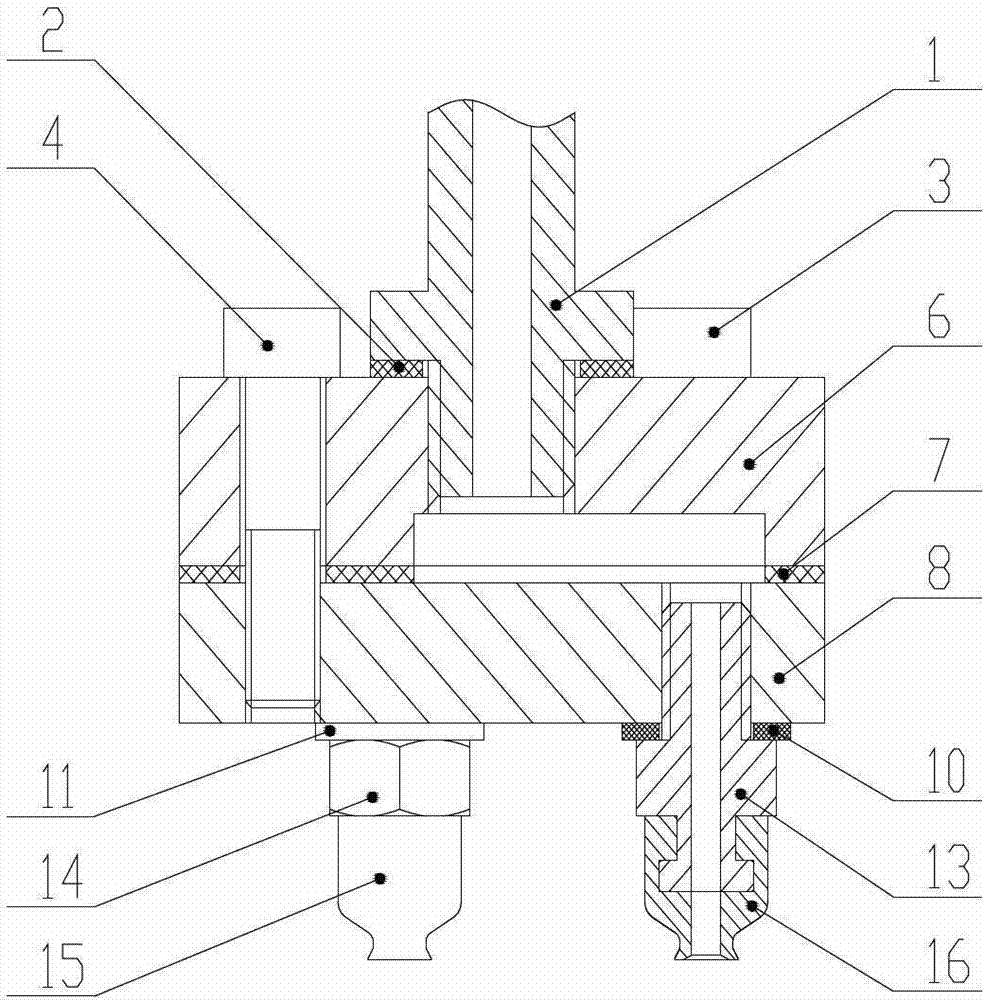

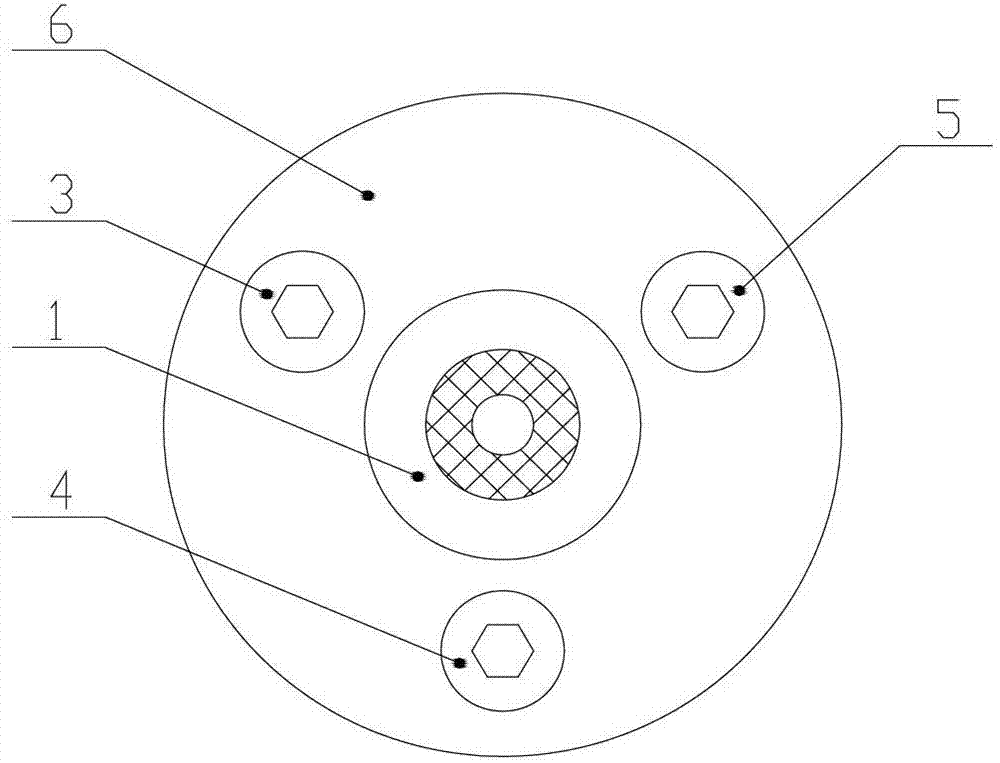

[0022] see figure 1 with 2 , The embodiment of the present invention is provided with a connecting plate (including an upper plate 6 and a lower plate 8 ), three metal suction heads 12-14 and three rubber suction nozzles 15-17.

[0023] The upper plate 6 and the lower plate 8 are locked by connecting screws 3-5, and a gasket 7 is installed between the upper plate 6 and the lower plate 8 to prevent air leakage. The lower surface of the upper plate 6 is provided with a trident-shaped (Y-shaped) groove 61, and a cavity is formed between the lower surface of the upper plate 6 and the lower plate 8, and serves as a gas channel. The center of the upper plate 6 is provided with a threaded through hole, which is not only the installation hole for the external suction device joint 1 and the vacuum suction cup, but also the vacuum port of the vacuum suction cup. Sealing gasket 2 is housed between the upper plate 6 upper end surface of external suction device joint 1 and connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com