Wristwatch chaining machine

A watch and chain machine technology, applied in the field of watch repair and testing devices, can solve the problems of limited use occasions, high noise, inability to install automatic mechanical watches of different specifications and multiple automatic mechanical watches of the same type at the same time, etc. Achieve the effect of ingenious structure, high efficiency and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

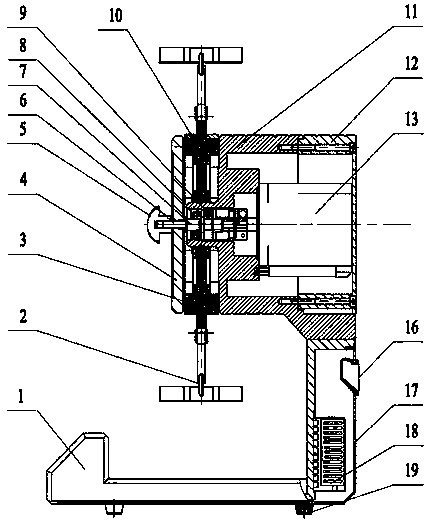

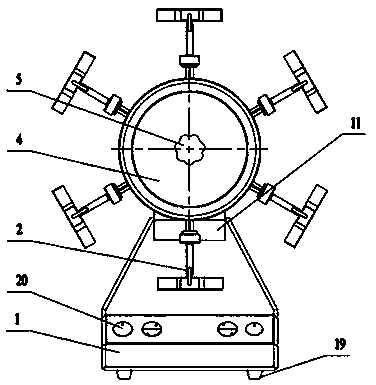

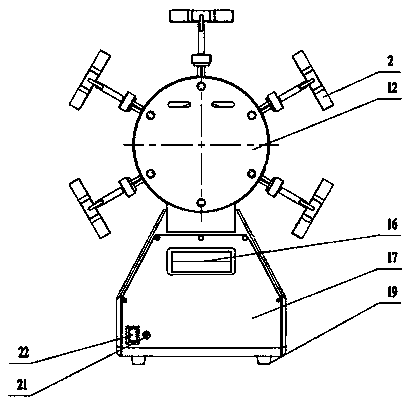

[0028] With reference to the accompanying drawings in the manual, the watch winding machine is described in detail below.

[0029] The structure of the watch winder of the present invention includes: the upper end of the base 1 is connected to the motor base 11 by screws, the motor 13 is fixed on the motor base 11 , and the rear end of the motor base 11 is connected to the back cover 12 . By setting the motor, only the motor is used as the sole power source, and no pneumatic or other forms of energy are required, and the application occasions are more extensive. The front end of the motor base 11 is provided with a bearing 8, and the bearing is limited by a snap spring. The cylindrical boss at the front end of the motor base 11 is connected to the central hole of the turntable 10. The turntable 10 is composed of an inner ring, a middle ring and an outer ring connected to each other. A plurality of through holes corresponding to the positions are set on each ring. The inner rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com