Connecting rod cap semifinished product true position detecting tool

A technology of semi-finished products and connecting rod covers, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of high detection cost, low detection efficiency, time-consuming, etc., and achieve lower use requirements, lower detection costs, and simple detection quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

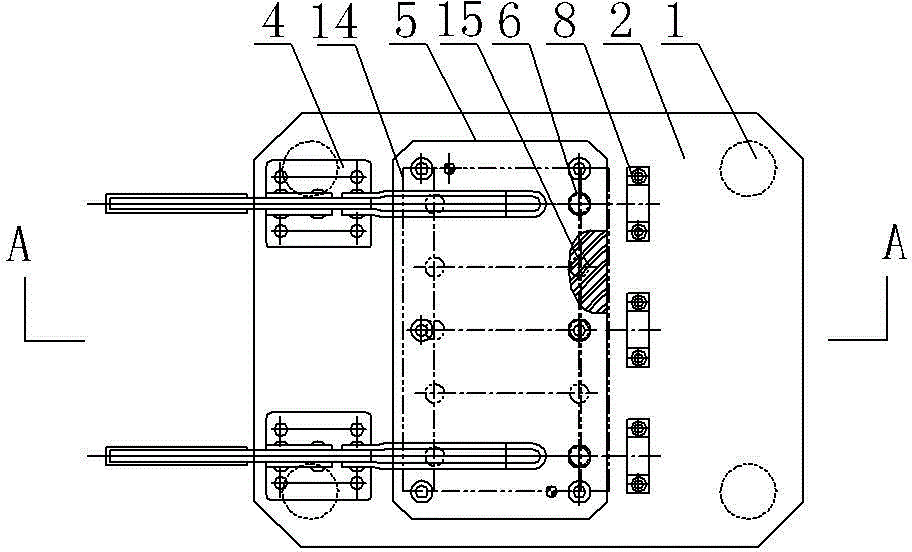

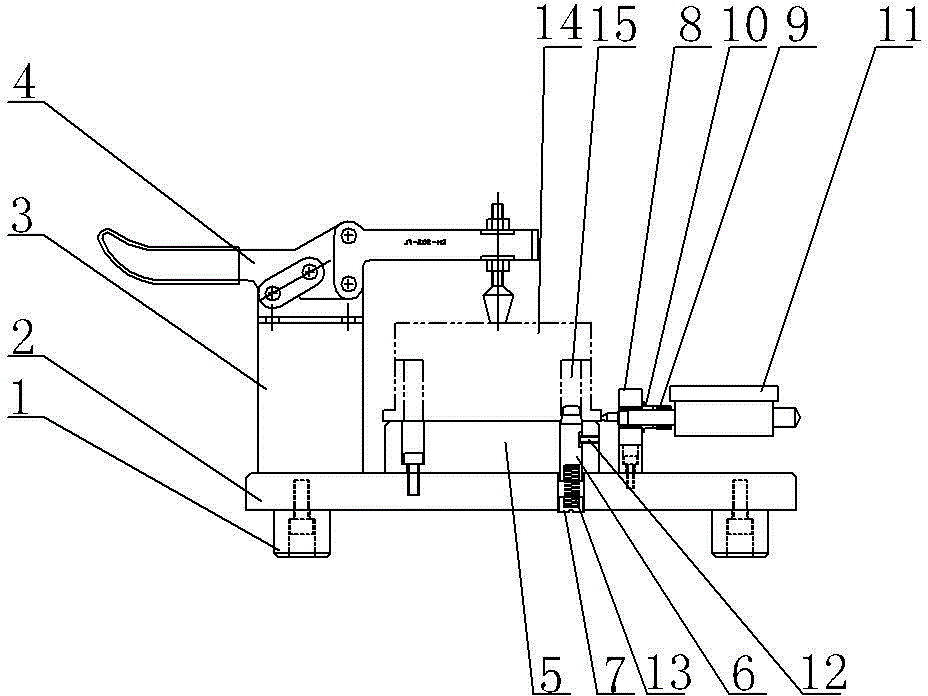

[0011] See figure 1 and figure 2 , the connecting rod cover semi-finished position inspection tool, which includes a bottom plate 2, the four corners of the bottom surface of the bottom plate 2 are installed with a foot 1 through bolts, which includes a quick clamp 4, a quick clamp seat 3, a reference seat 5, a taper pin 6 and a mechanical watch 11, One side of the reference seat 5 is fixed on the bottom plate 2 by bolts, and the other side is inserted and positioned on the bottom plate 2 by two taper pins 6 evenly distributed longitudinally. At both ends, the quick clamp 4 is fixed to the quick clamp seat 3 through its flange surface, the screw hole 15 on the bottom surface of the semi-finished connecting rod cover 14 to be tested is positioned by the tapered end of the taper pin 6, and the longitudinal ends of the upper surface are pressed by the quick clamp Fixed; including the limit pin 12, the bottom plate 2 has a perforation at the insertion place of the taper pin 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com