Water balloon system

a water balloon and system technology, applied in the field of water balloon systems, can solve the problems of achieve the effect of reducing the time and energy required to tie multiple water balloons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

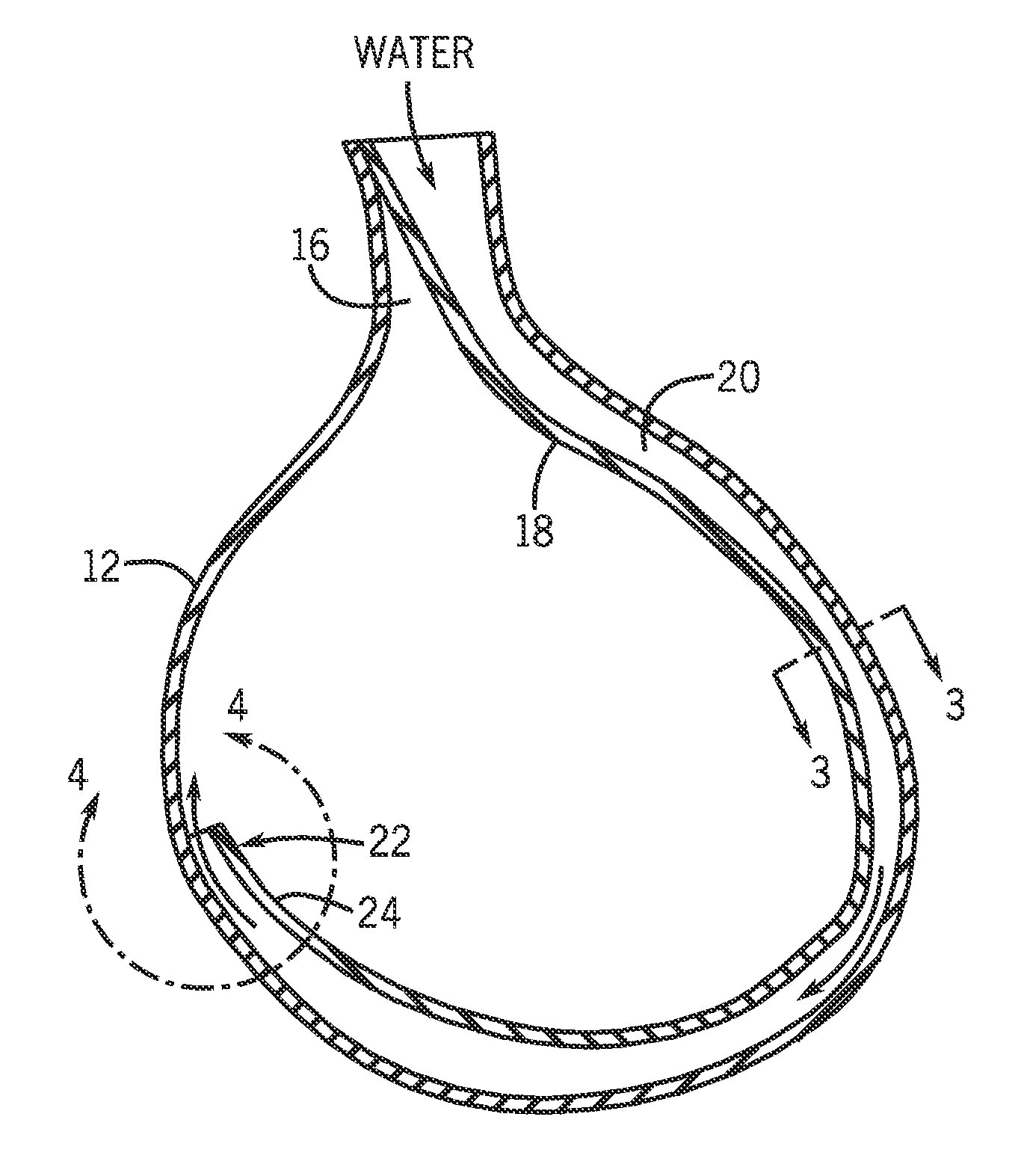

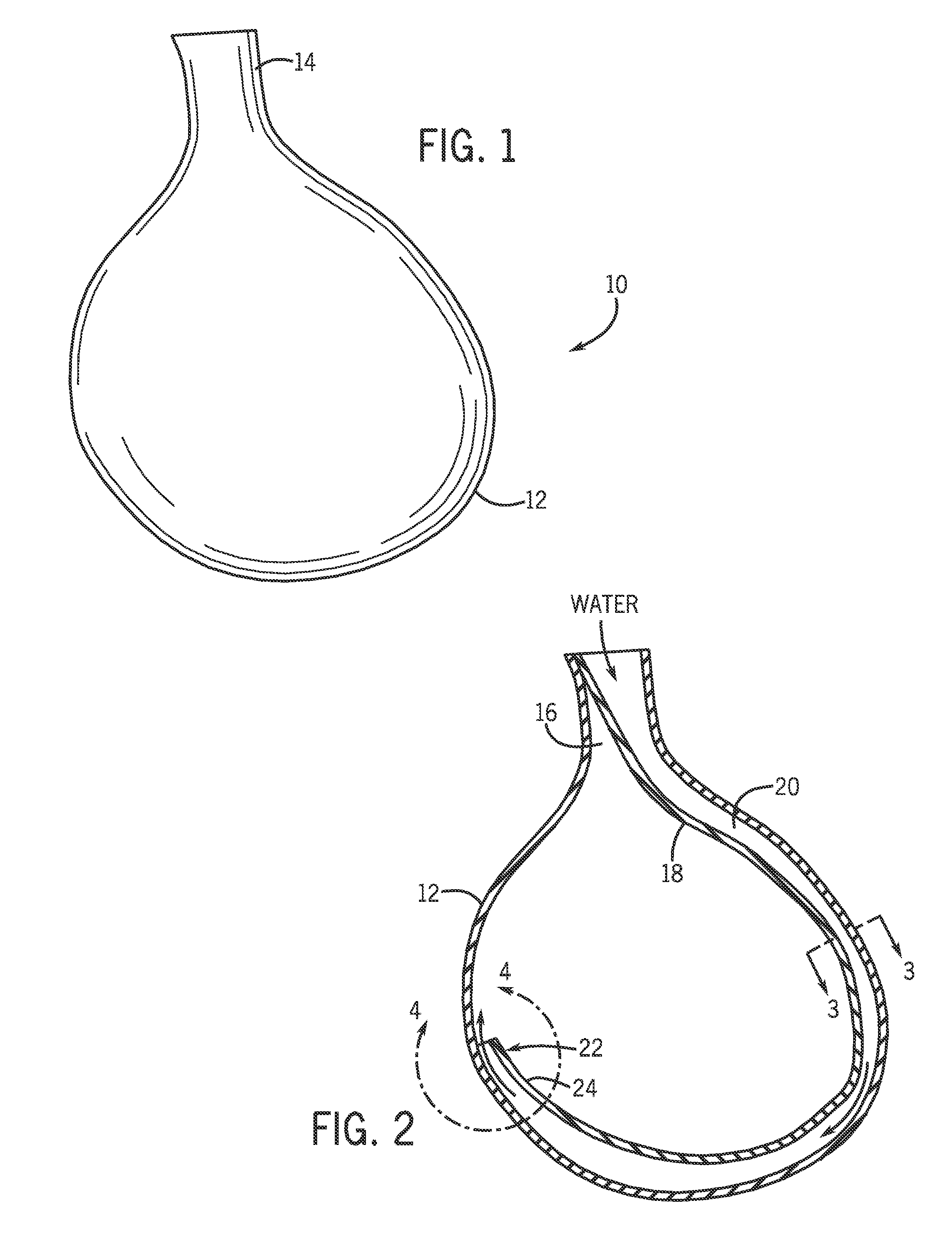

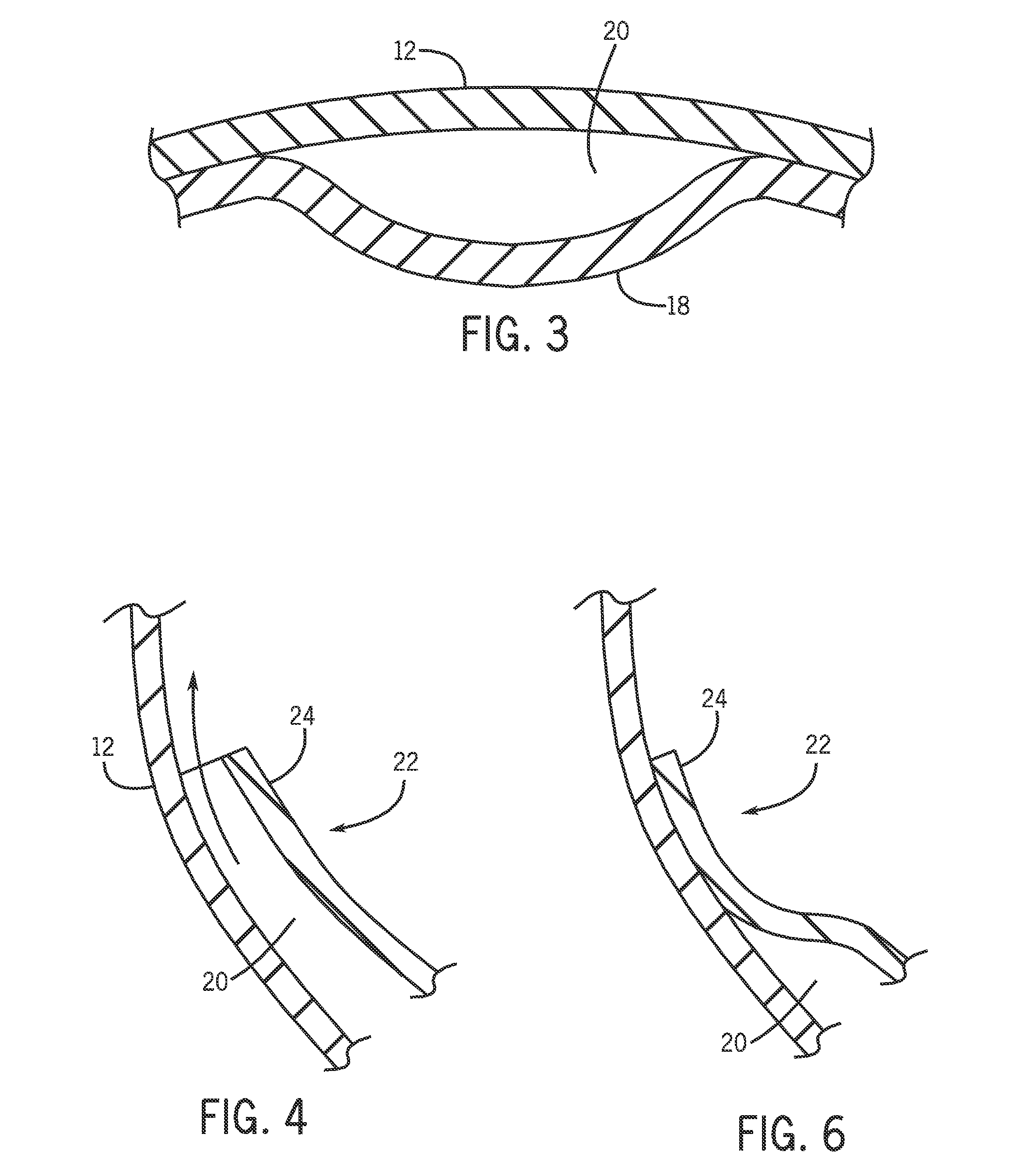

[0017]With reference to FIGS. 1 through 8, there is shown a preferred embodiment of a tie-less water balloon 10 and a multi-balloon filling assembly 28. The water balloon 10 is made of elastic materials standard in balloon manufacture (e.g., rubber) and includes an outer wall 12 and an inner membrane 18. The outer wall 12 and the inner membrane 18 together form a one-way channel 20. In one example, the balloon 10 is formed by dipping the inner membrane 18 into a liquid latex solution.

[0018]The balloon 10 further includes a neck 14 and a seal 16. The neck 14 of the balloon 10 opens into the one-way channel 20 and allows water 26 to flow into the balloon 10, (While water is preferred, balloon 10 may be filled with other liquids as desired by a user.) Once water 26 stops flowing into the balloon 10, the seal 16 prevents the water 26 from escaping through the neck 14.

[0019]As illustrated in FIGS. 2-6, the balloon 10 is filled with water 26 through the neck 14 and channel 20, The water 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elastic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com