Small Rb atom frequency marking cavity bubble system

A technology of rubidium atomic frequency standard and cavity bubble, which is applied in the field of rubidium atomic frequency standard, can solve the problems that the microwave cavity cannot be made of magnetic screen material, the utilization rate of atomic filling space is small, and the volume of the rubidium atomic frequency standard is reduced. The effect of reducing the difficulty of design and debugging, simple structure and high performance index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

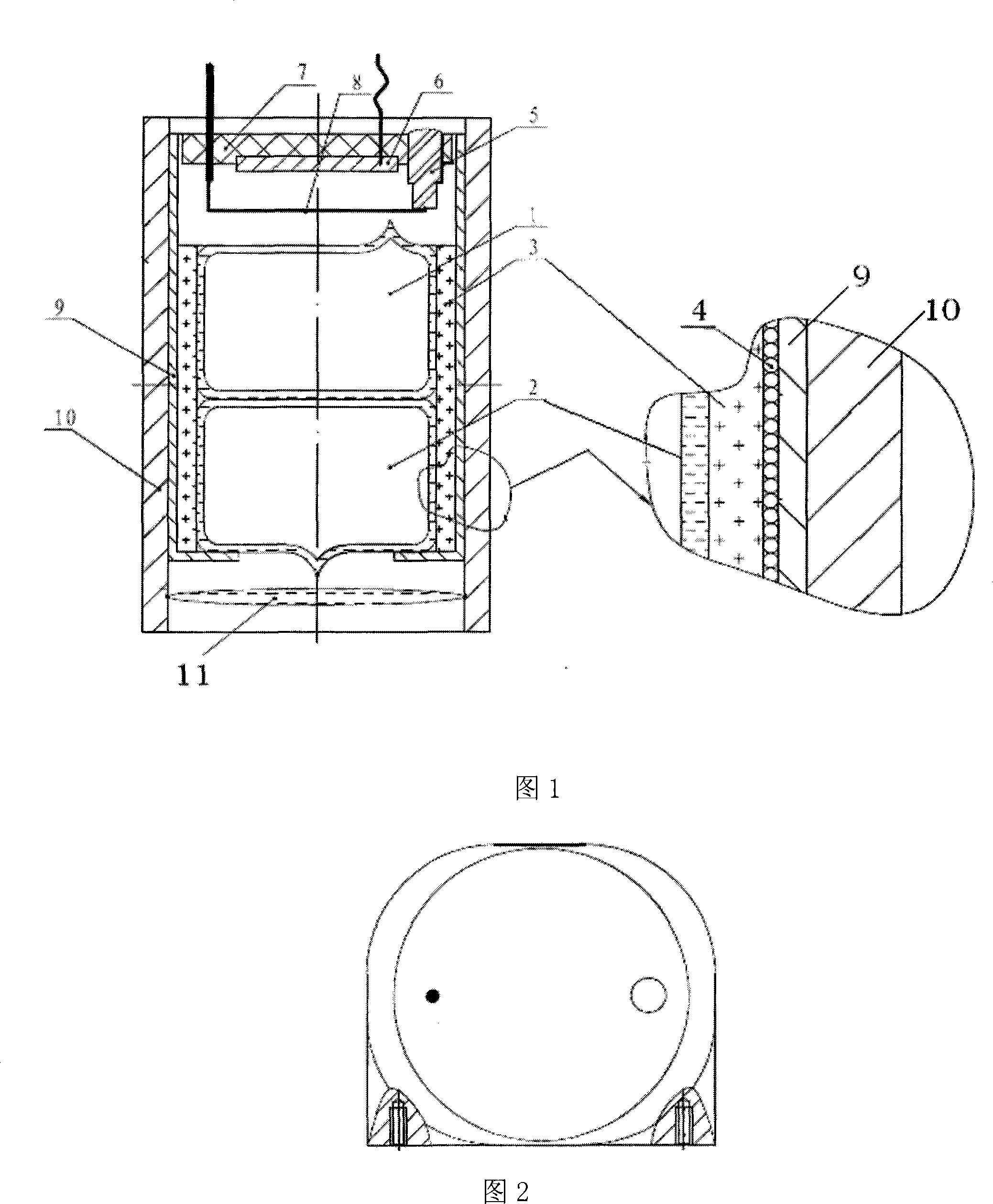

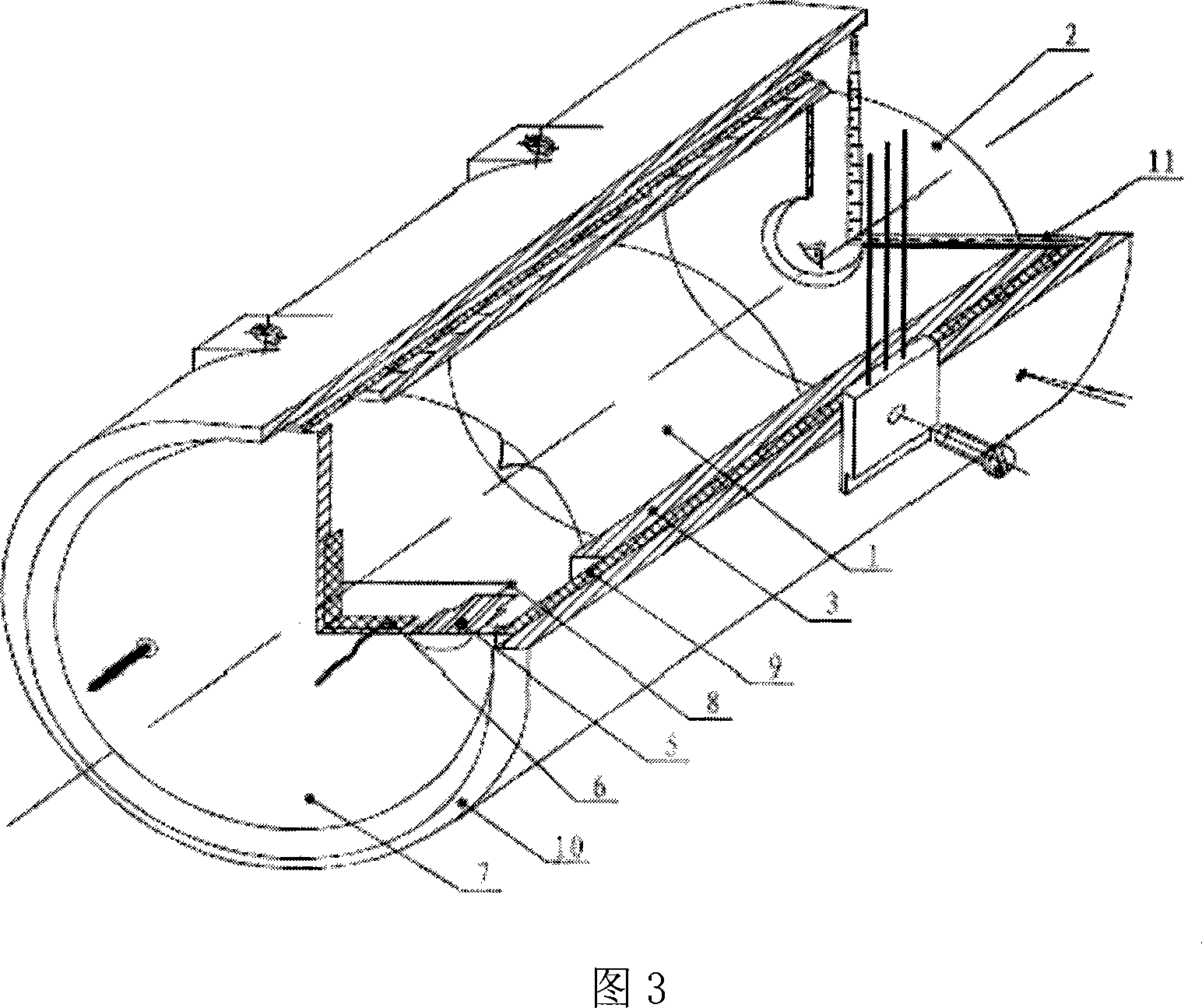

[0021] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing:

[0022]Figures 1 to 3 describe the miniaturized rubidium atoms in the cavity step frequency multiplication mode composed of absorbing bubble 1, filter bubble 2, dielectric tube 3, microwave cavity tube 9, photoelectric components, C field coil 4 and heating constant temperature device The best embodiment of frequency standard cavity bubble system. The cylindrical microwave cavity 9 based on the cylindrical TE111 mode is made of high magnetic permeability metal material. The metal material with high magnetic permeability can be iron-nickel alloy or cymbal alloy, or pure iron. In order to reduce microwave loss and improve performance, the inner surface of the microwave cavity 9 may be plated with a gold layer or a silver layer. One end of the microwave cavity 9 is a fully open end as a part for placing passages in the cavity, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com