Glass fiber impregnating agent as well as preparation method and application of glass fiber impregnating agent

A glass fiber and sizing technology, applied in the field of glass fiber thermosetting resin technology, can solve the problems of small migration of combustible content, sensitive environment temperature and humidity, complex winding process, etc., and achieve small migration of combustible content, less hairiness and compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

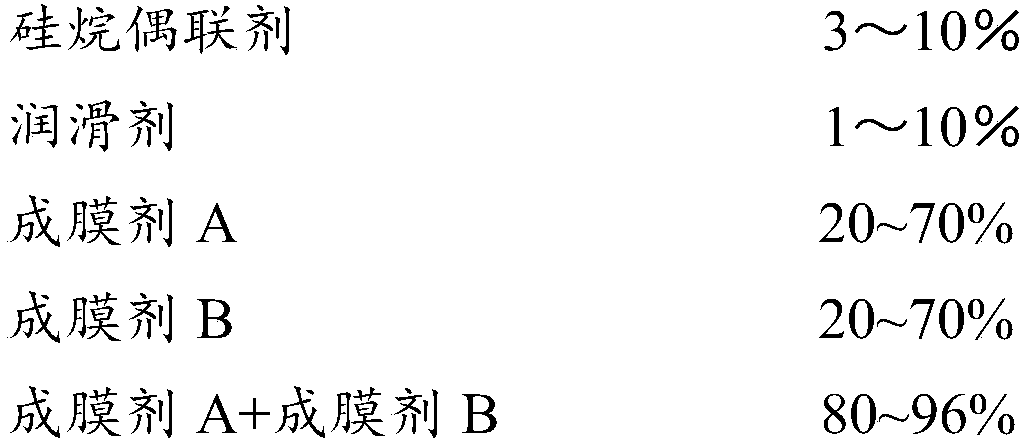

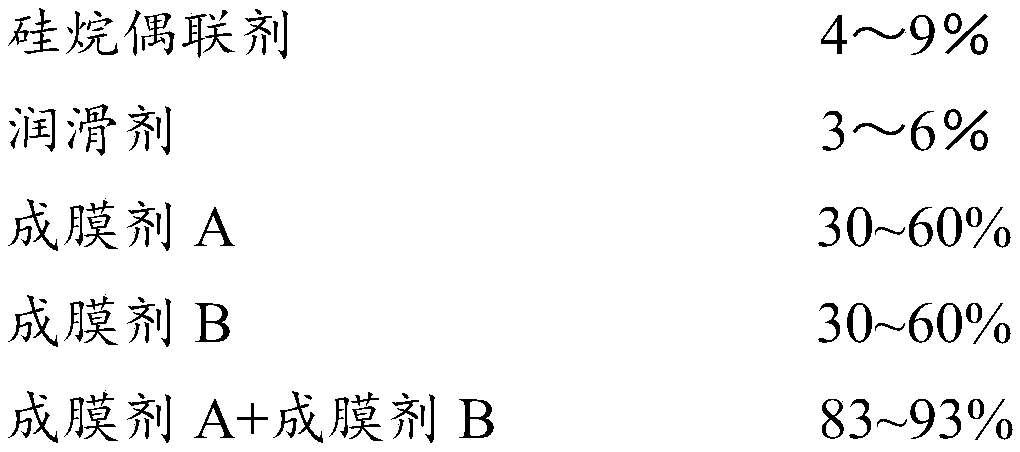

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the embodiment of the present invention and comparative example 1 comprises the following steps:

[0046] 1) Weigh 40-50% of the total water mass into the preparation container, then slowly add the silane coupling agent, and continue stirring for 25-30 minutes;

[0047] 2) Weigh water 3-10 times the mass of the lubricant and heat it to 50-60°C, then add the lubricant into the water at 50-60°C, stir thoroughly to prepare a lubricant solution, and then add it to the preparation container;

[0048] 3) Add film-forming agent A to water whose mass is 2 to 3 times the mass of film-forming agent A, and fully stir to prepare film-forming agent A emulsion; add film-forming agent B to water whose mass is 2-3 times the mass of film-forming agent B times the amount of water, fully stirred to prepare film-forming agent B emulsion; film-forming agent A emulsion and film-forming agent B emulsion were added to the preparation container;

[0049] 4) Add the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com