Environmentally friendly size and its sizing process

A sizing and environmental protection technology, applied in the field of textile sizing, can solve the problems of insufficient strength of starch sizing, difficult to desizing of PVA, large environmental pollution, etc. stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

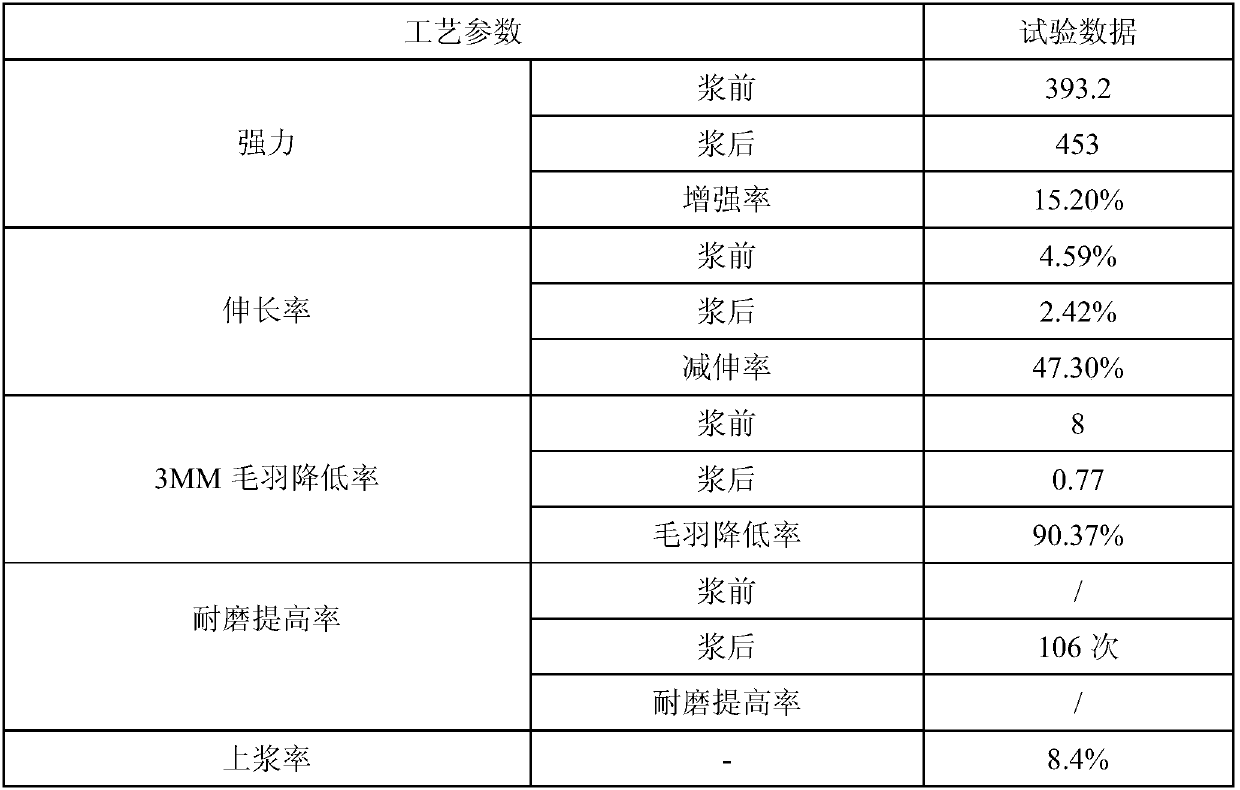

Embodiment 1

[0030] An environment-friendly slurry is composed of the following components in parts by weight: 10 parts of FLOLINE SIZE P, 100 parts of starch, 25 parts of acrylic acid, 0.3 part of FLOSIZE PA 760H, and 6 parts of wax.

[0031] The warp variety is: cotton 80 / 2.

[0032] The sizing process includes the following steps:

[0033] (1) Put water in the mixing bucket;

[0034] (2) Add FLOLINE SIZE P and starch in sequence to the mixing tank, raise the temperature to 75±2°C, add acrylic acid and FLOSIZE PA 760H in turn, and then add wax, the concentration of the slurry is 9%, and heat up to 100°C for 65 minutes;

[0035] (3) Inject the slurry obtained in step (2) into the sizing machine and keep the temperature at 93°C;

[0036] (4) sizing the planned warp yarn on the sizing machine, the size used for sizing is the size obtained in step (3), and the pressure roller pressure is 21KN; 0.5.

[0037] (5) Adjust the moisture regain of the yarn to 8.5% during the sizing driving proc...

Embodiment 2

[0053] A kind of environment-friendly slurry, is made up of the following components by weight: 10 parts of FLOLINE SIZE P, 100 parts of starch, 25 parts of acrylic acid, 0.3 part of FLOSIZE PA 760H, 6 parts of wax, synergist (BP-A sizing enhancer Efficacy agent) 10 parts.

[0054] The warp variety is: cotton 80 / 2.

[0055] The sizing process includes the following steps:

[0056] (1) Put water in the mixing bucket;

[0057] (2) Add FLOLINE SIZE P and starch in turn to the mixing tank, heat up to 75±2°C, add acrylic acid and FLOSIZE PA 760H in turn, then add wax and synergist, the concentration of the slurry is 9%, and heat up to 100°C. pulp for 65 minutes;

[0058] (3) Inject the slurry obtained in step (2) into the sizing machine and keep the temperature at 93°C;

[0059] (4) sizing the planned warp yarn on the sizing machine, the size used for sizing is the size obtained in step (3), and the pressure roller pressure is 21KN; 0.5.

[0060] (5) Adjust the moisture regai...

Embodiment 3

[0076] An environment-friendly slurry is composed of the following components in parts by weight: 10 parts of FLOLINE SIZE P, 102 parts of starch, 27 parts of acrylic acid, 0.4 parts of FLOSIZE PA 760H and 6 parts of wax.

[0077] Warp yarn variety: 40 cotton warp yarns.

[0078] The sizing process includes the following steps:

[0079] (1) Put water in the mixing tank;

[0080] (2) Add FLOLINE SIZE P and starch in turn to the mixing tank, raise the temperature to 75±2°C, add acrylic acid and FLOSIZE PA 760H in turn, then add wax, the concentration of the slurry is 10%, and heat up to 100°C for 60 minutes;

[0081] (3) Inject the slurry obtained in step (2) into the sizing machine and keep the temperature at 92°C;

[0082] (4) sizing the planned warp yarn on the sizing machine, the size used for sizing is the size obtained in step (3), and the pressure roller pressure is 18KN; 0.3.

[0083] (5) Adjust the moisture regain of the yarn to 8.5% during the sizing driving proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com