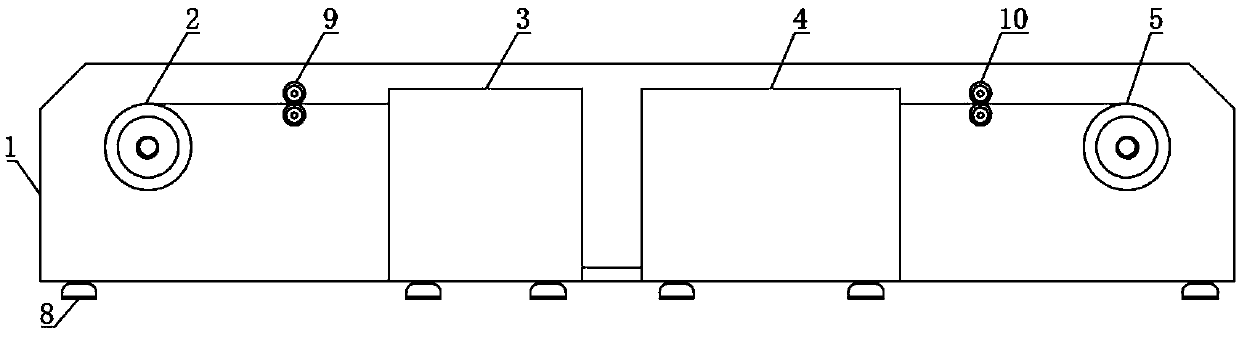

Device for treating yarns by applying plasma technology

A kind of technical treatment and plasma technology, applied in the field of textile fabric surface treatment, can solve the problems of insufficient yarn performance, unable to meet the needs of yarn versatility, etc., and achieve the effect of soft yarn, simple structure and renewable energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for processing yarn using plasma technology, comprising the steps of:

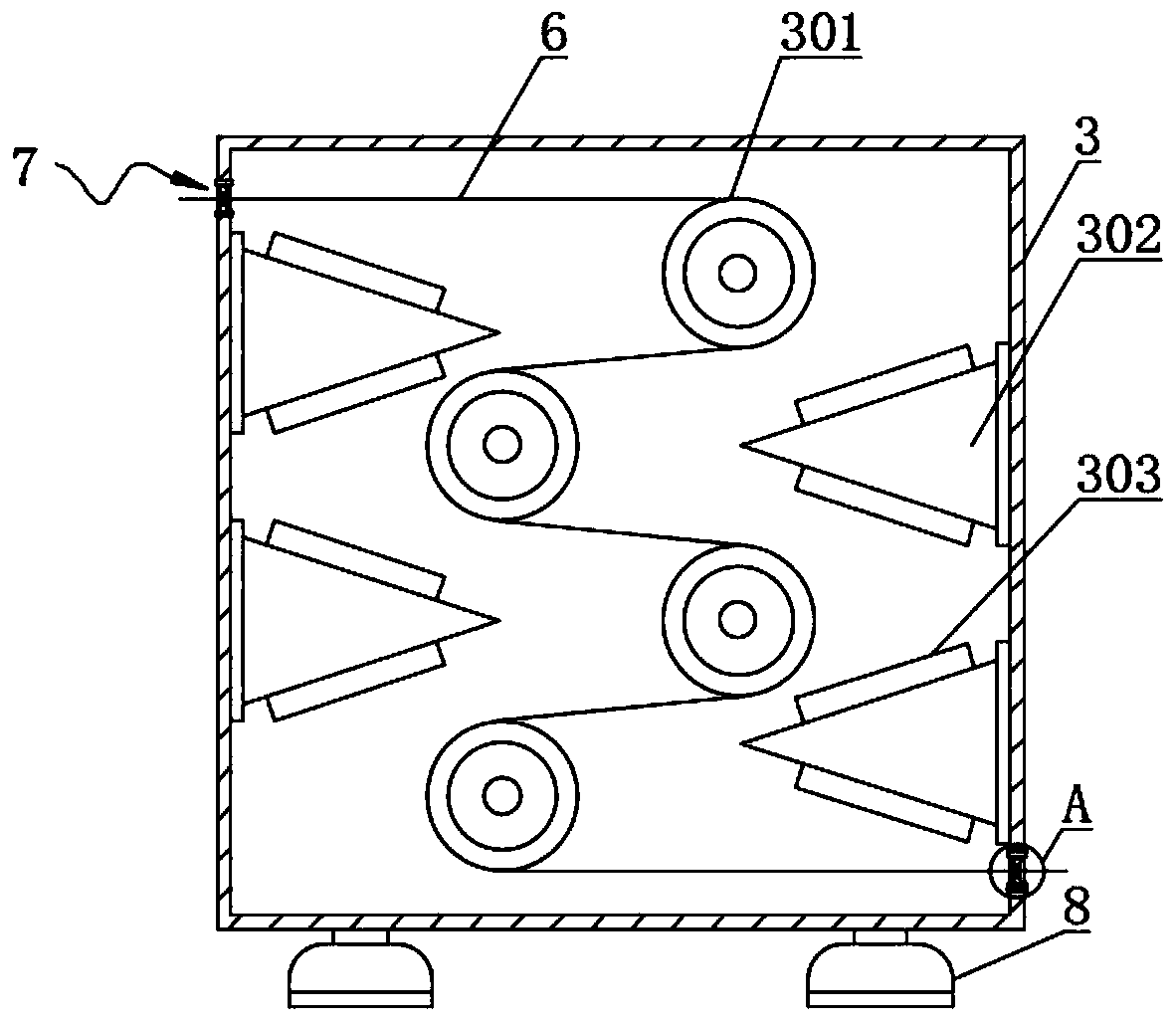

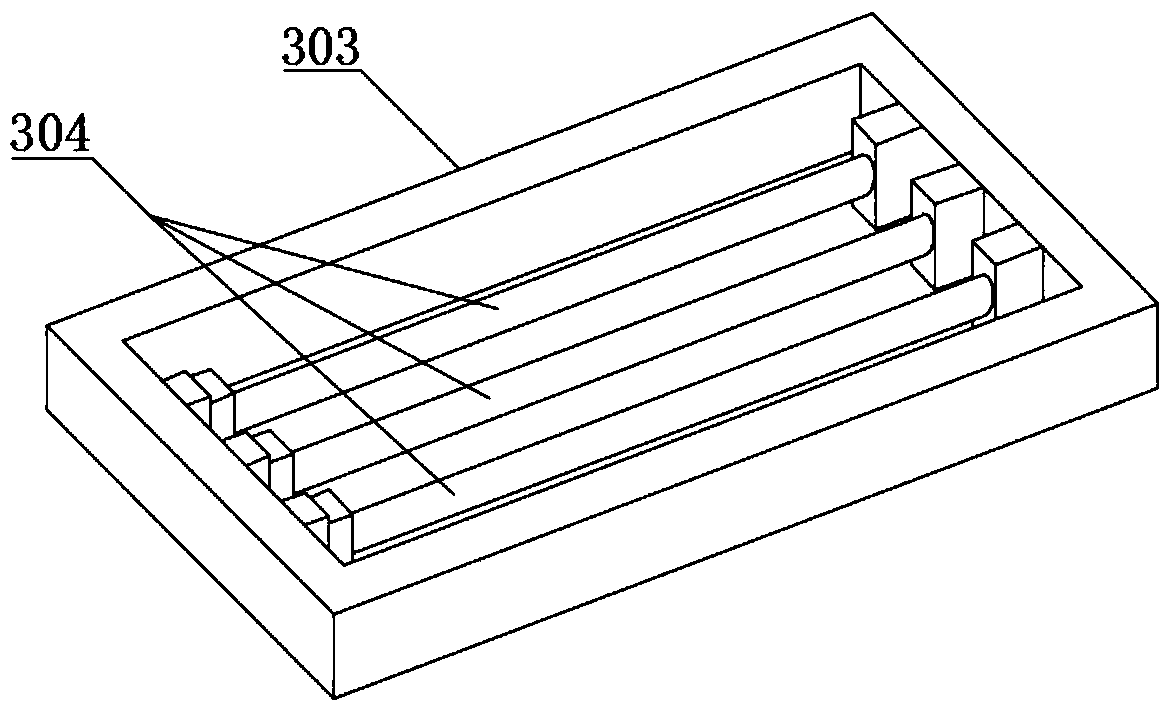

[0031] S1: pretreatment, the wool top 6 with a fineness range of 25um is sent to the preheating chamber 3, the heating temperature of the infrared heating tube 304 is 140°C, and the heating time is 10min;

[0032] S2: Plasma treatment, the pretreated top 6 is sent to the plasma modification chamber 4, air is introduced into the plasma modification chamber 4, and 15,000V is applied between the electrodes of the ceramic roller 403 and the plasma discharge roller 404 under standard atmospheric pressure The voltage is used to perform plasma treatment on the top 6, and the treatment time is 5 minutes.

Embodiment 2

[0034] A method for processing wool tops using plasma technology, comprising the steps of:

[0035] S1: pretreatment, transfer the wool top 6 with a fineness range of 235um to the preheating chamber 3, the heating temperature of the infrared heating tube 304 is 140°C, and the heating time is 10min;

[0036]S2: Plasma treatment, the pretreated top 6 is sent to the plasma modification chamber 4, air is introduced into the plasma modification chamber 4, and 10,000V is applied between the electrodes of the ceramic roller 403 and the plasma discharge roller 404 under standard atmospheric pressure The voltage is used to perform plasma treatment on the top 6, and the treatment time is 15 minutes.

[0037] Working principle: as figure 2 As shown, the wool top 6 is staggered in the preheating chamber 3, and the infrared heating tubes 304 on the two side walls of the preheating chamber 3 fully heat the upper and lower sides of the wool top 6, and the speed of the receiving roller 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com