Alkali-free continuous glass fiber yarn with high content of FeO and preparation method of alkali-free continuous glass fiber yarn

A glass fiber yarn and content technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of unreachable fiber length, high surface tension, and affecting yield, etc., achieve good uniformity, increase wire drawing speed, and glass hardening speed slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Further, a method for preparing non-alkali continuous glass fiber yarn with high FeO content, comprising the following steps:

[0030] 1) Weigh the raw materials through the batching system, put them into the pneumatic mixing delivery tank, pulse the compressed air 20 to 40 times in the mixing delivery tank, and then become a uniform batching material, each batching amount is 500kg~2000kg; batching material The compressed air is used to transport it to the kiln head bin, and then it is put into the kiln by a screw feeder. At a temperature of 1300-1800 ° C, the batch material is melted to form glass liquid, and the glass liquid passes through the main passage, and then flows into the working passage. 1200~1400℃;

[0031] 2) The molten glass enters the platinum alloy leaking plate, and there are 800 to 1600 leaking nozzles at the bottom of the leaking plate. The molten glass passes through the leaking nozzles, cooling fins, spray water, oiler, cluster wheel, and cable gui...

Embodiment 1

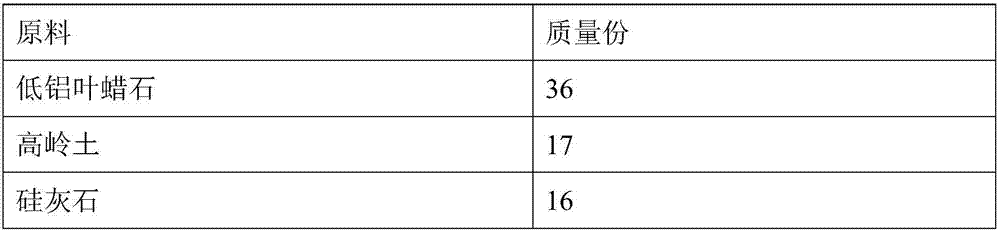

[0035] A raw material of alkali-free continuous glass fiber yarn with high FeO content is composed of the ingredients shown in Table 1.

[0036] The raw material composition of table 1 embodiment 1

[0037] raw material

Embodiment 2

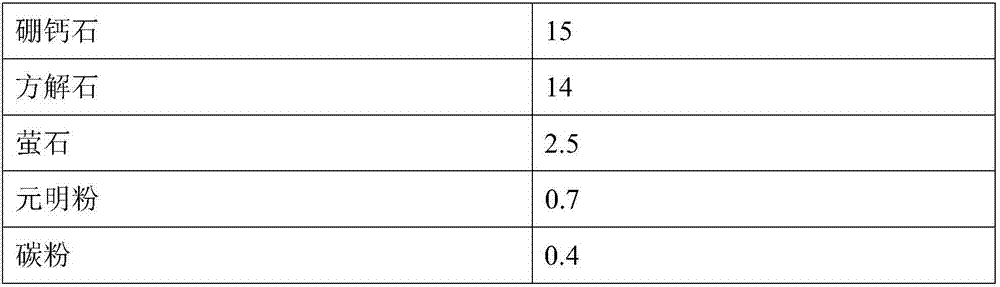

[0039] A raw material of alkali-free continuous glass fiber yarn with high FeO content is composed of the ingredients shown in Table 2.

[0040] The raw material composition of table 2 embodiment 2

[0041] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com