Glass fiber sizing agent and application thereof

A technology of glass fiber and sizing agent, which is applied in the field of glass fiber sizing agent to achieve the effect of improving infiltration speed, good compatibility and fast infiltration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

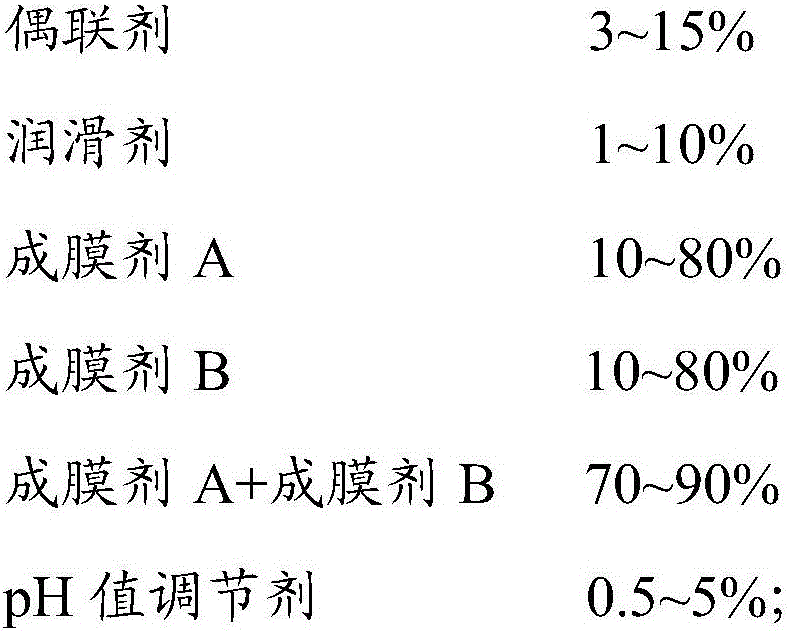

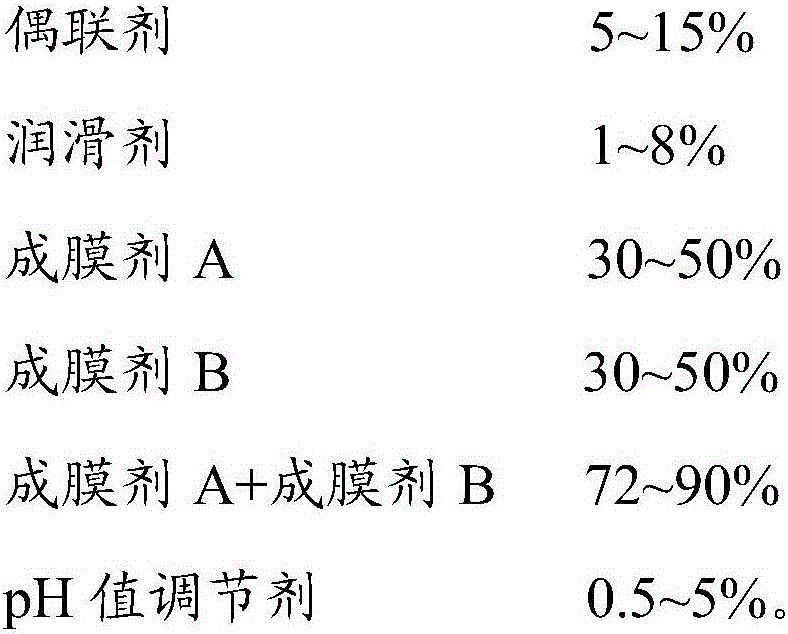

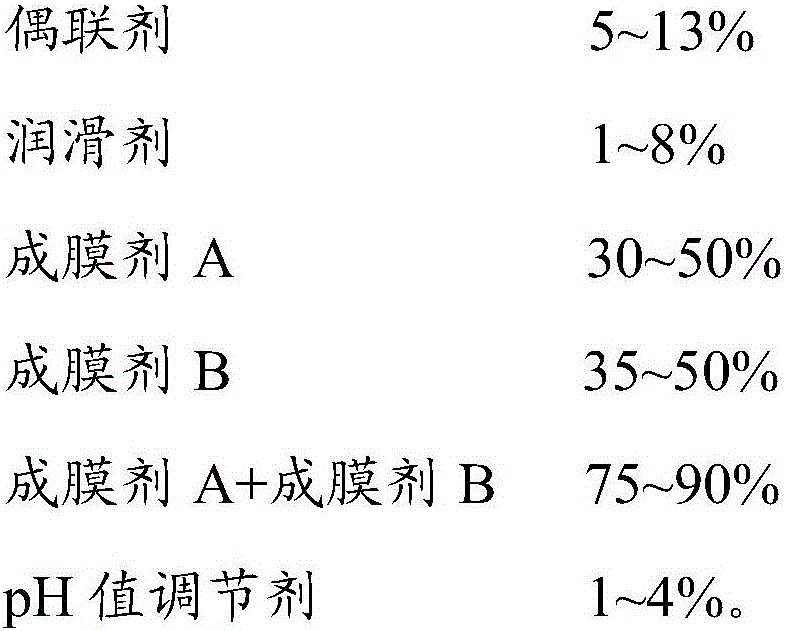

[0047] In the embodiment of the present invention, the content of water accounts for 94% of the total mass of the wetting agent. Table 1 shows the percentage value of the solid mass of each component in the wetting agent to the total mass of the wetting agent. The corresponding value of each component is the mass percentage / %. Among them, the coupling agent uses γ-methacryloxypropyl trimethoxysilane (production grade is A-174), γ-aminopropyltriethoxysilane (production grade is A-1100), γ- One or more of (2,3-glycidoxy)propyltrimethoxysilane (A-187) and vinyltris(β-methoxyethoxy)silane (A-172); Lubricant uses PEG1000; film-forming agent A uses unsaturated polyester resin emulsion (production grade is Neoxil 954); film-forming agent B uses epoxy resin emulsion (production grade is BH-620); pH regulator uses acetic acid.

[0048] Table 1 list of specific examples of wetting agent

[0049]

[0050] Wherein, embodiment 1, the coupling agent of embodiment 4 selects the coupling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com