Glass fiber-aramid fiber mixed fabric and production method thereof

A technology of glass fiber aramid fiber and woven fabric, which can be used in non-woven fabrics, textiles and paper making, etc., and can solve problems such as easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

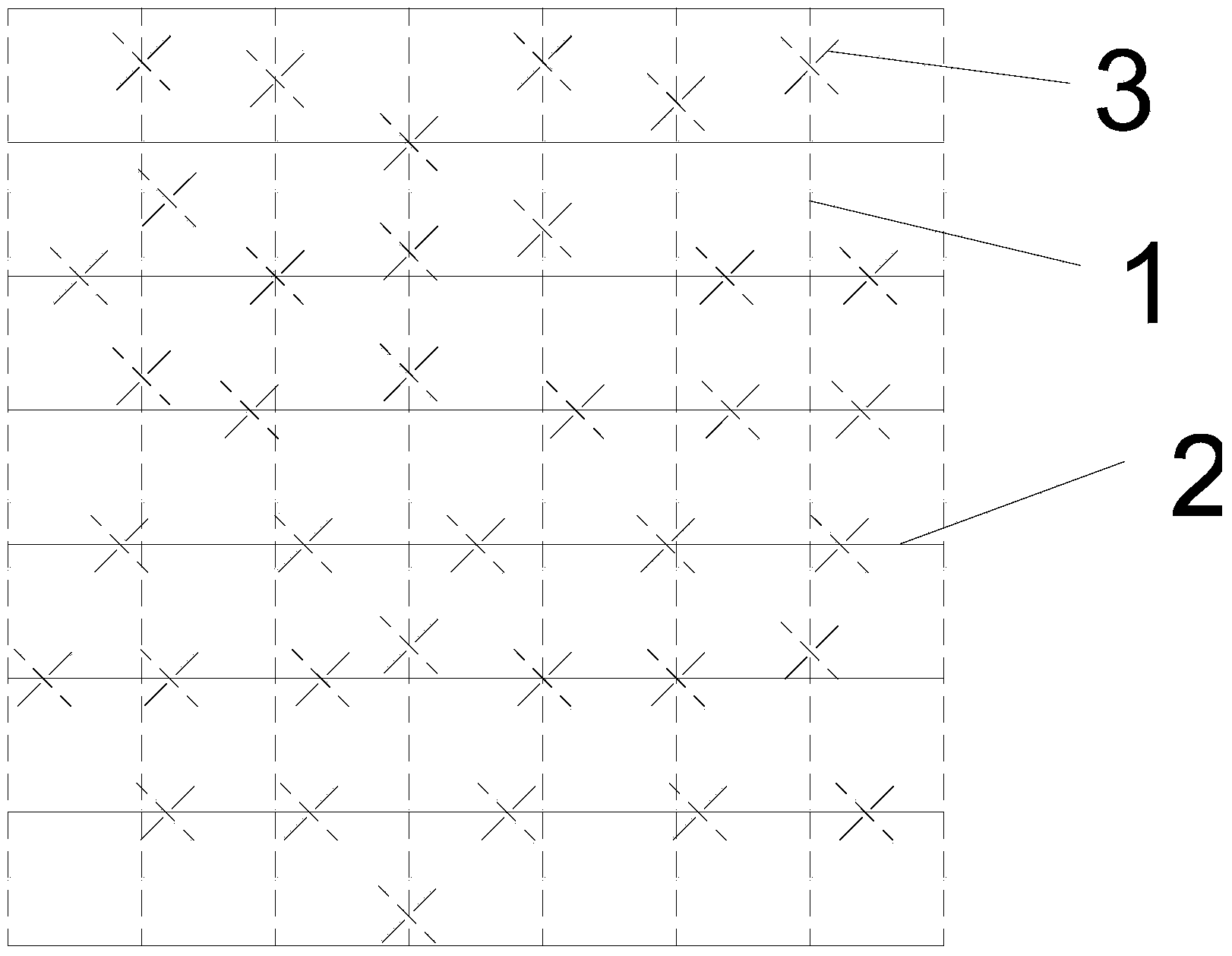

[0020] figure 1 In the above, since the warp fiber bundle and the weft fiber bundle are laid in layers, the weft fiber bundle is represented by a solid line, and the warp fiber bundle is represented by a dotted line. The weft fiber bundle is laid on the warp fiber bundle, while the chopped The yarns are evenly scattered between the warp and weft fiber bundles, and the chopped strands are represented by crossed dashed lines. The positional relationship of laying up and down of warp fiber bundles and weft fiber bundles is not limited to figure 1 The laying method described in , can also be that the weft fiber bundle is laid under the warp fiber bundle.

[0021] see figure 1 , glass fiber and aramid blended fabrics, including warp fiber bundles 1, weft fiber bundles 2, and chopped strands 3, the warp fiber bundles and weft fiber bundles are eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com