Glass fiber continuous strand mat impregnating agent

A technology of glass fiber and sizing agent, which is applied in the field of glass fiber continuous strand mat sizing agent, which can solve the problems of affecting glass fiber, single fiber breakage, sizing agent can not fully meet the glass fiber protection effect, etc., and achieve good resin binding , low static electricity, fast resin soaking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention will be further described below with specific examples, but protection scope of the present invention is not limited to this:

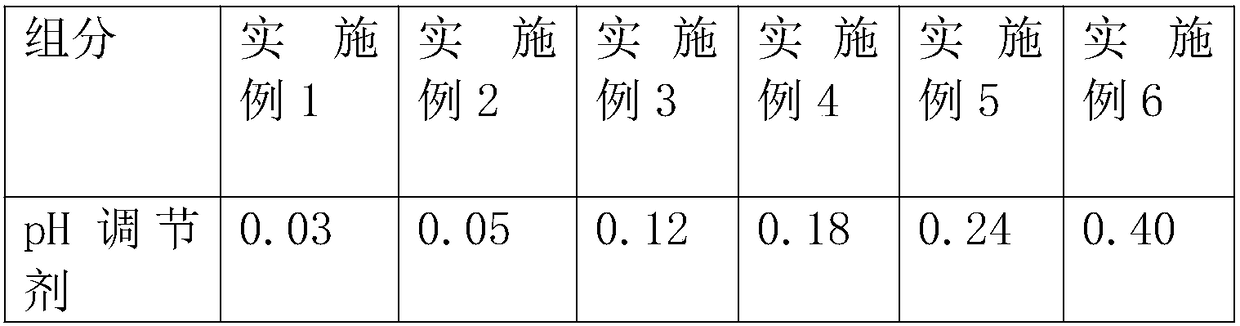

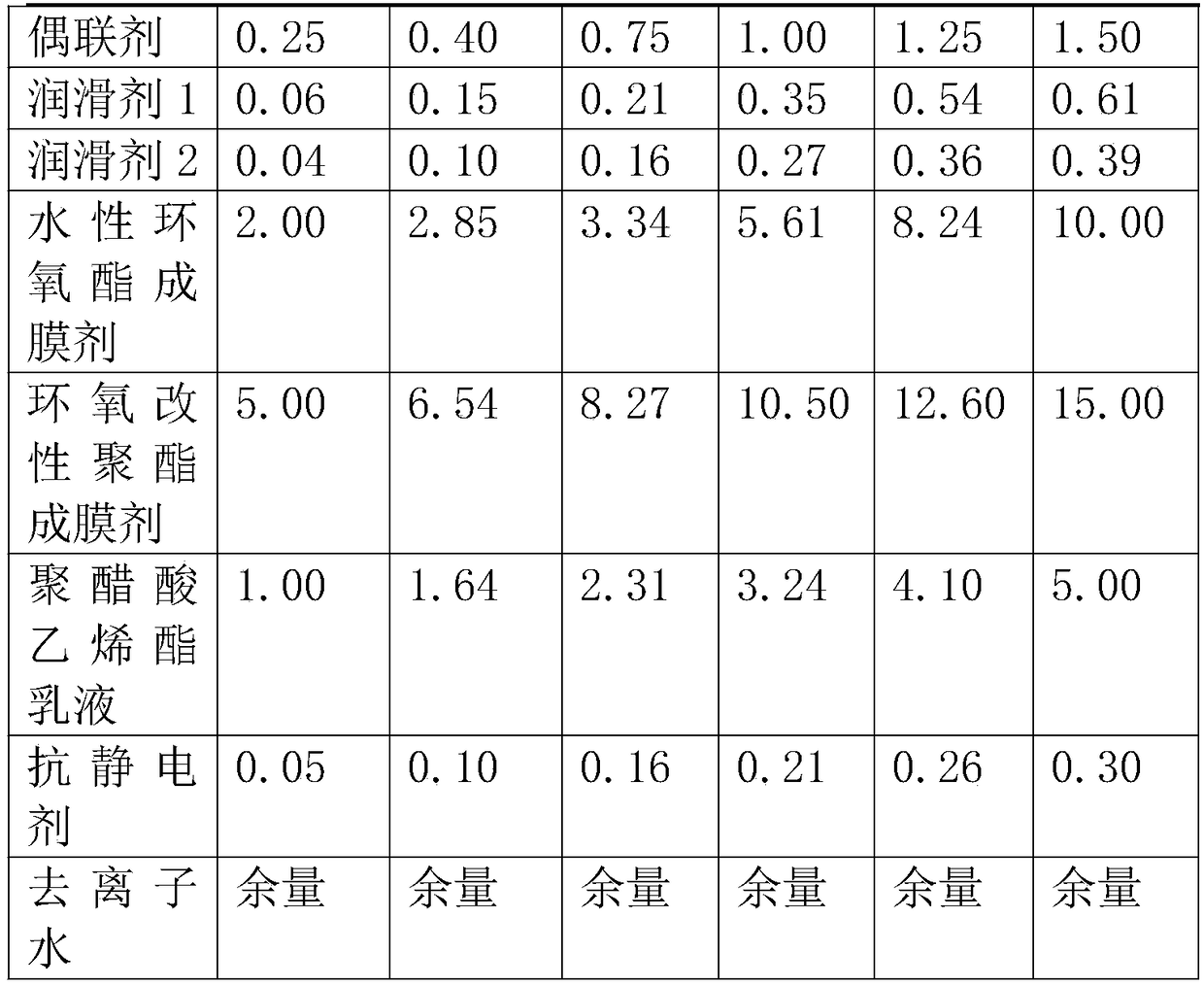

[0026] Among the examples of the present invention: the coupling agent is γ-(methacryloxy) propyl trimethoxysilane, the model is KH570; the pH regulator is technical grade glacial acetic acid; lubricant 1 is cationic lubricant 6760, lubricant 2 is the non-ionic lubricant type PEG300; the water-based epoxy ester emulsion is P-70, the epoxy modified polyester emulsion is FILCO 339, and the polyvinyl acetate emulsion is MC-2046; the antistatic agent is lithium nitrate. The recipe is shown in the table below.

[0027] Table 1 glass fiber continuous strand mat formula embodiment

[0028]

[0029]

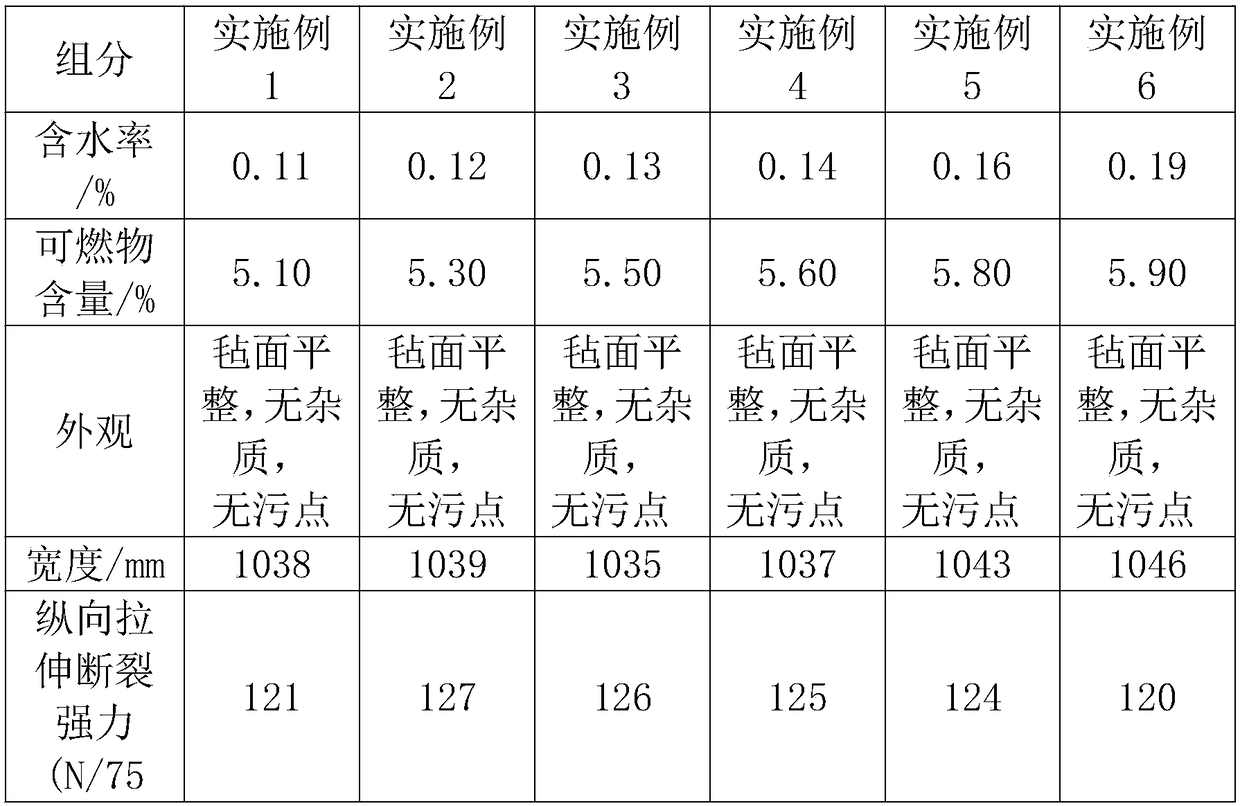

[0030] The continuous precursor mat of the present invention adopts the "two-step method" molding process and equipment, the diameter of the single filament is 13 μm, the number of strands bundled is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com