A kind of glass fiber sizing agent and its application

A glass fiber and sizing technology, which is applied in the field of glass fiber sizing, can solve the problem of glass fiber dispersion, hairiness, electrostatic penetration speed, light transmittance, glass fiber and matrix resin refractive index mismatch, and production problems. The light transmittance of the lighting board is not good, etc., to achieve the effect of fast soaking speed, good chopping performance, and meeting the production process and performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

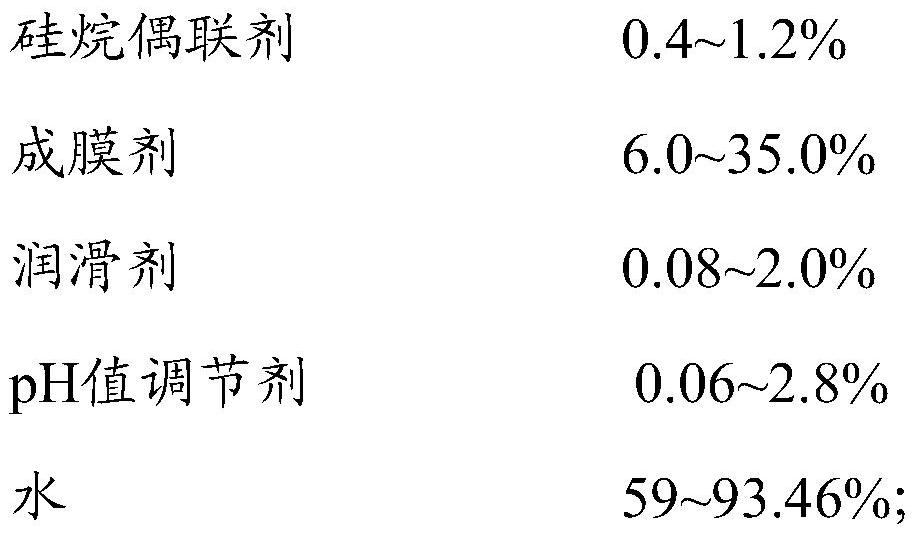

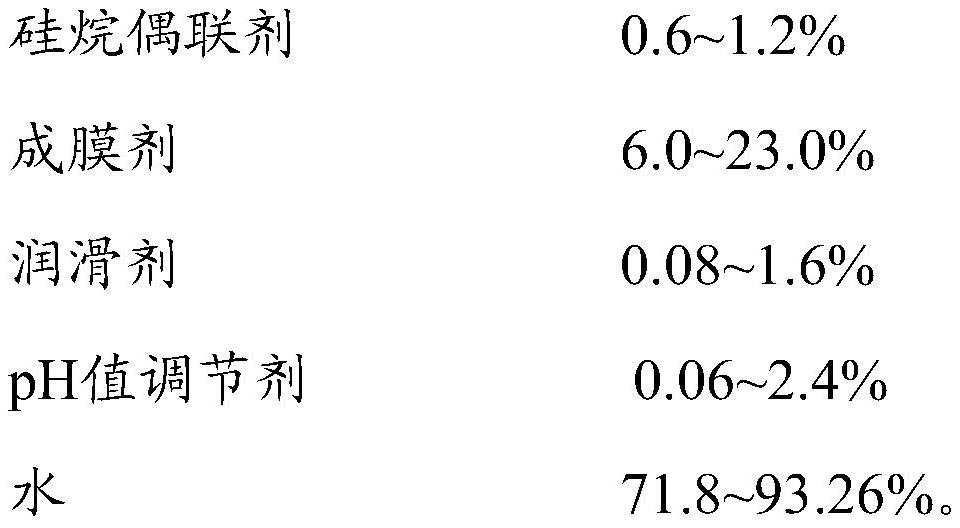

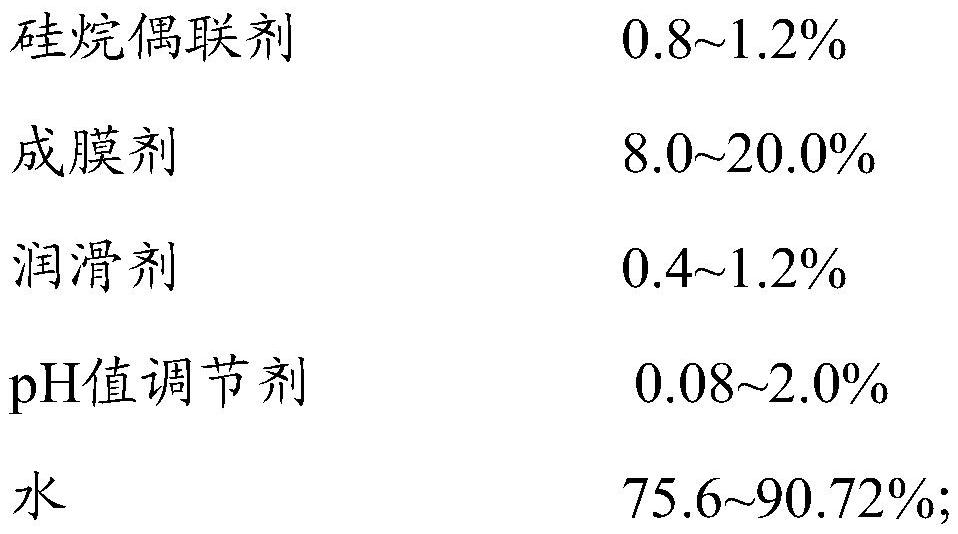

[0051] Table 1 shows specific examples of the content of each component in some sizing agents, and the corresponding values of each component are mass percent / %. It should be pointed out that the specific example data in Table 1 does not limit the protection scope of the present invention.

[0052] in,

[0053] Coupling agent A is a silane coupling agent with amino groups, the model is S-70;

[0054] Coupling agent B is γ-methacryloxypropyltrimethoxysilane coupling agent, model A-06;

[0055] Film-forming agent A is an acrylic modified epoxy emulsion, model T-08, produced by the first branch of Jushi Group, and its Tg is between 10 and 25 °C;

[0056] Film-forming agent B is a silane coupling agent-modified cross-linked PVAc emulsion, model T-66, produced by the first branch of Jushi Group, and its Tg is between 18 and 30 °C;

[0057] Lubricant A is silicone emulsion;

[0058] Lubricant B is a cationic surfactant using polyethyleneimine quaternary ammonium salt;

[0059...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com