Modified polyvinyl acetate emulsion, preparation method and uses thereof

A polyvinyl acetate, emulsion technology, used in textiles and papermaking, graft polymer adhesives, adhesive types, etc., to achieve the effect of improving penetration speed and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

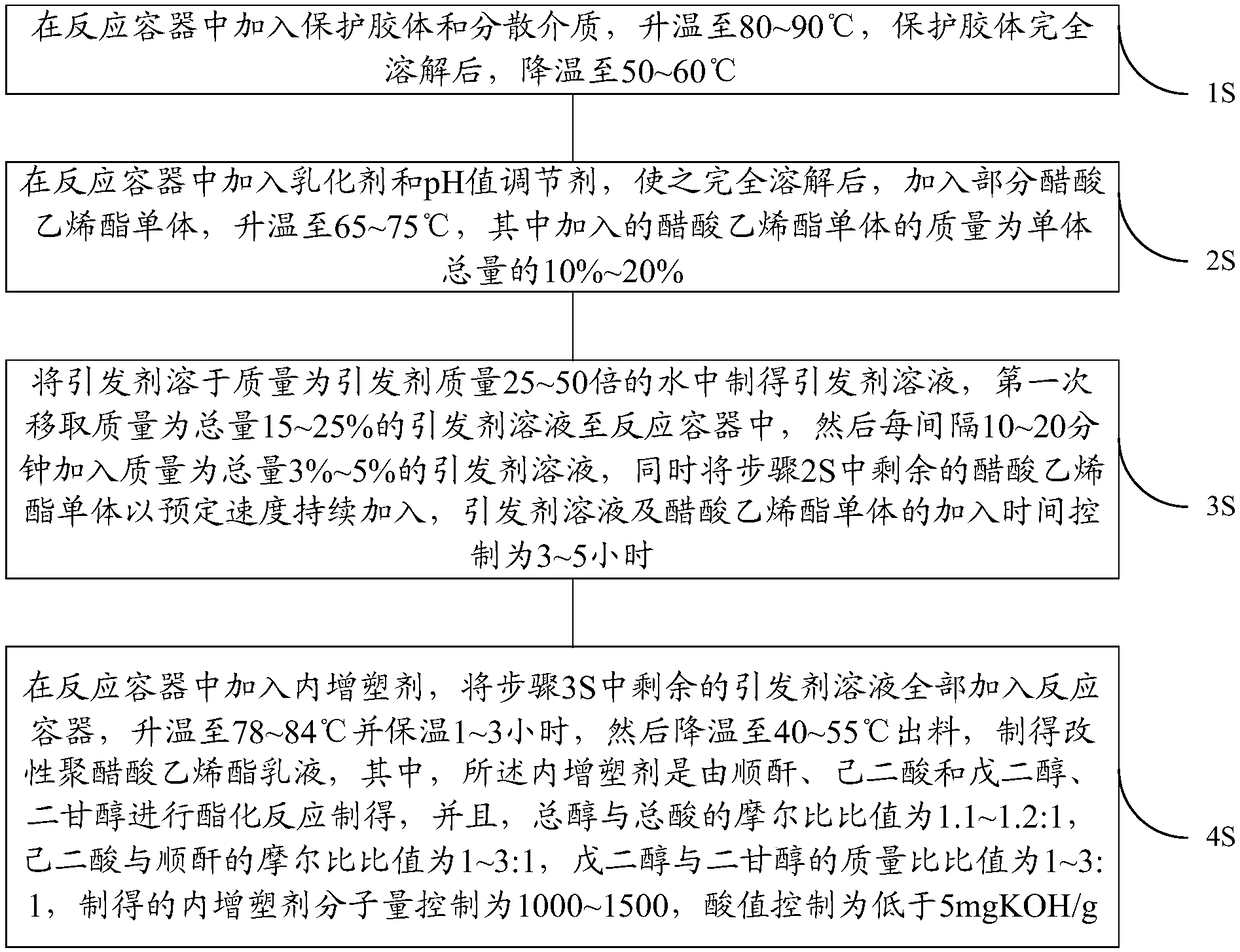

Method used

Image

Examples

Embodiment 1

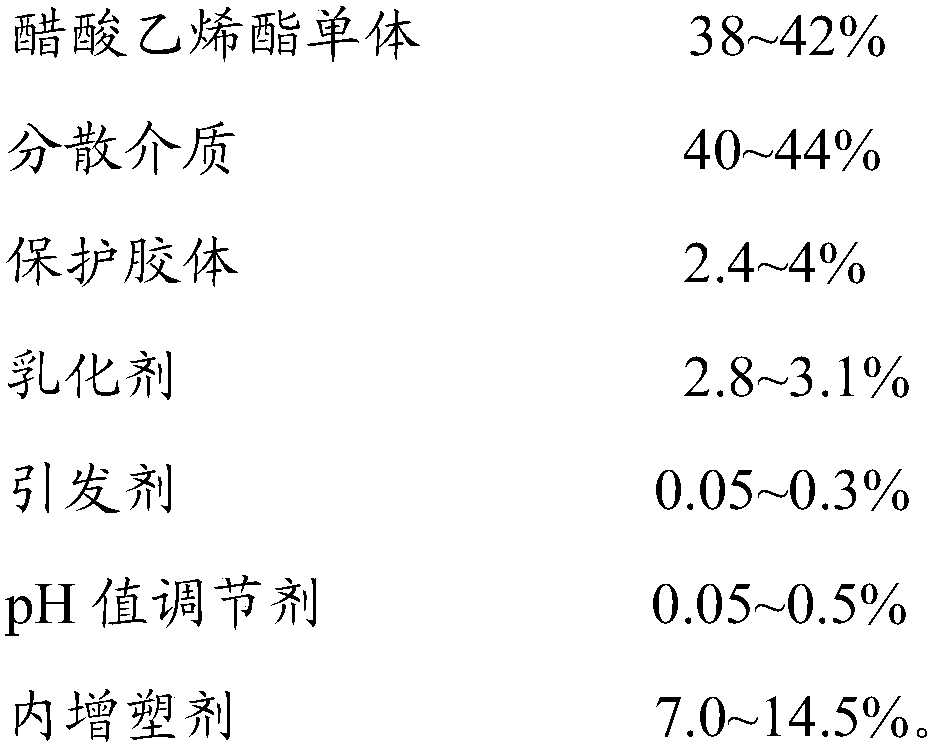

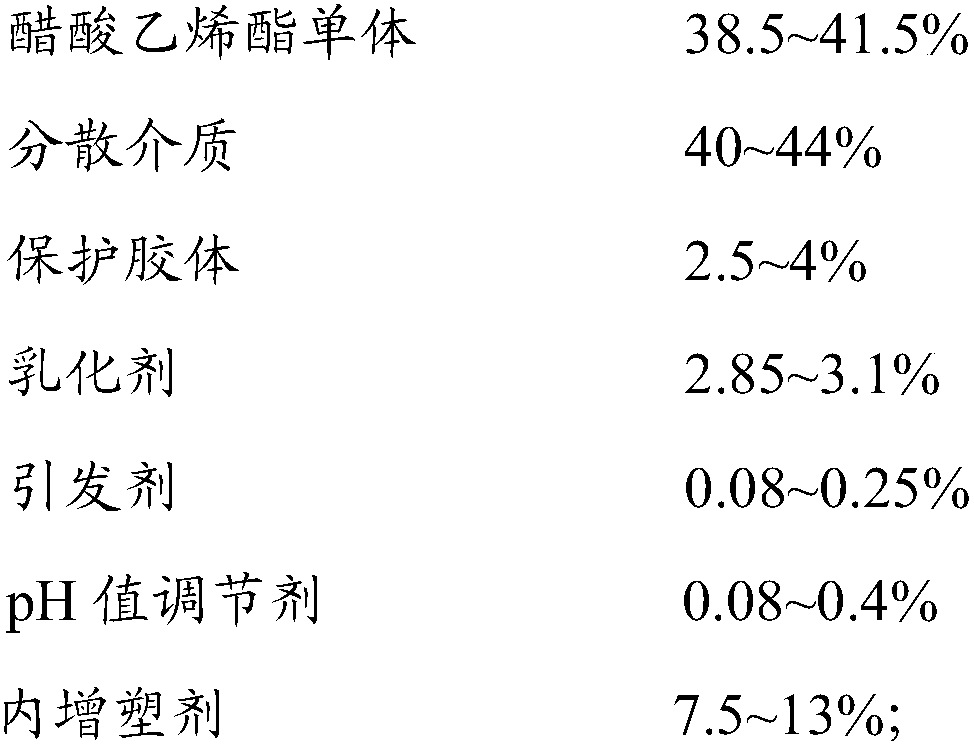

[0064] Weigh each component by mass percentage, wherein, the protective colloids are three kinds of grades BP-20, BP-17 and BF-17, the emulsifier A uses the non-ionic emulsifier of Emcol EO-50, and the emulsifier B Anionic emulsifier SM-618 was used.

[0065] Each component is carried out the preparation of modified polyvinyl acetate emulsion as follows:

[0066] 1S Add 3g BP-20, 3g BP-17, 3g BF-17 and 100g dispersion medium into the reaction vessel, raise the temperature to 90°C, after the polyvinyl alcohol is completely dissolved, cool down to 60°C, where the dispersion medium is water;

[0067] 2S add 3g emulsifier A and 4g emulsifier B and 0.3g NaHCO to the reaction vessel 3 , after completely dissolving, add 15g of vinyl acetate monomer and heat up to 68°C;

[0068] 3S will be 0.4g (NH 4 ) 2 S 2 o 8 Dissolve in 15g of water to prepare the initiator solution, pipette 3g of the initiator solution into the reaction vessel for the first time, then add 0.6g every 15 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com