A kind of glass fiber sizing agent for transparent mat and its preparation method and application

A technology for sizing and felt, applied in the field of glass fiber sizing for transparent felt and its preparation, can solve the problems of many white filaments in glass fiber felt, short service life of products, poor compatibility, etc., and achieve good transparency, The effect of high product strength and good weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

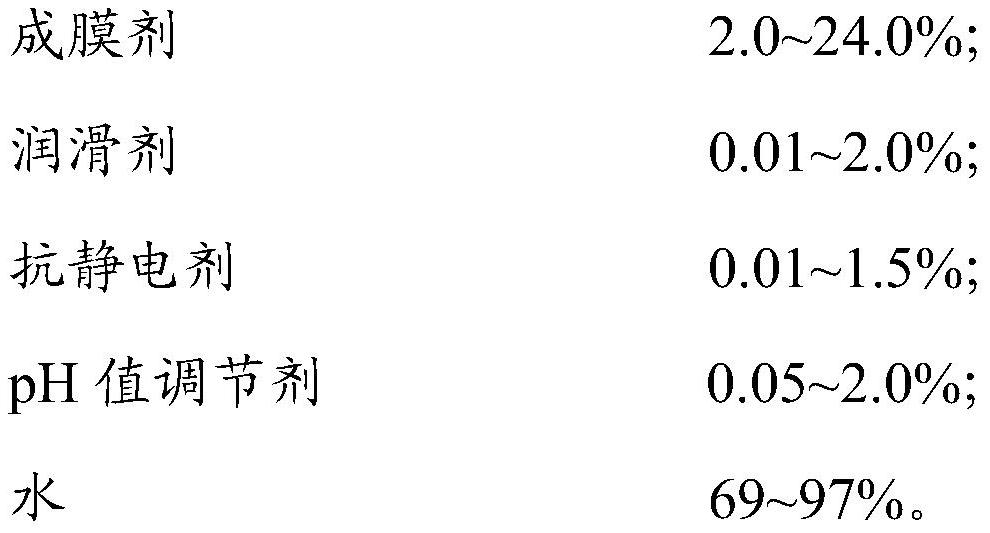

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of this sizing agent comprises the following steps:

[0052] Pre-dispersed silane coupling agent: In the first disperser, add deionized water with a weight of 20 to 40 times the weight of γ-methacryloxypropyl trimethoxysilane, add a pH value regulator, and control the pH value at 3.5~4.0, add γ-methacryloxypropyl trimethoxysilane under stirring state, control the stirring speed at 50~150r / min, and stir for 10~20 minutes;

[0053] In the second disperser, add deionized water whose weight is 10 to 30 times the weight of the composition of cationic benzylaminosilane, add a pH adjuster, control the pH value at about 3.5 to 4.5, and add cationic benzylamino silane under stirring For the composition of silane, the stirring speed is controlled at 50-150r / min, stirring for 10-20 minutes;

[0054] Pre-dissolve and dilute the lubricant: add deionized water at 85-90°C in an amount 15-25 times the weight of the lubricant in the first container, then add glac...

Embodiment

[0063] In the examples of the present invention, the coupling agent γ-methacryloxypropyl trimethoxysilane is produced by EVONIC Company, and the model is MEMO; the cationic benzylaminosilane is produced by EVONIC Company, and the model is 1161;

[0064] The lubricant uses alkyl imidazoline derivatives;

[0065] The antistatic agent adopts quaternary ammonium methyl sulfate, AO5620 and ammonium chloride;

[0066] The pH regulator uses acetic acid,

[0067] Film-forming agent: Bisphenol A type unsaturated polyester emulsion is from JS-111 of COIM company in Italy, and bisphenol A type epoxy emulsion is from Jushi Group TX-209;

[0068] The final pH value of the infiltrating agent is controlled at 3.5-6.0, and the LOI value is controlled at 0.25-0.8%.

[0069] Table 1 list of specific examples of wetting agent

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com