Method and device for infiltrating reinforced material and resin glue continuously

A technology of reinforcing materials and glues, which is applied to devices and coatings that apply liquid to the surface. It can solve the problem of insufficient infiltration of reinforcing materials, and achieve the effect of solving insufficient infiltration, prolonging infiltration time and good wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

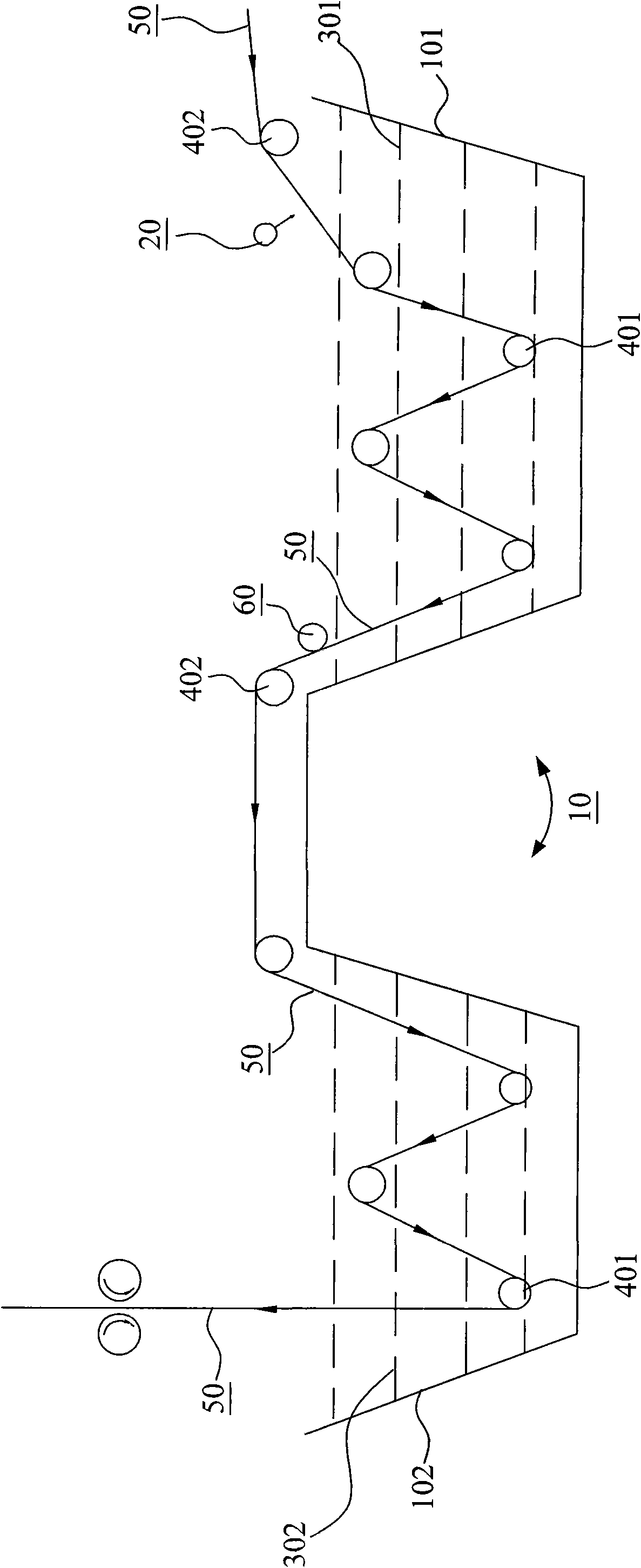

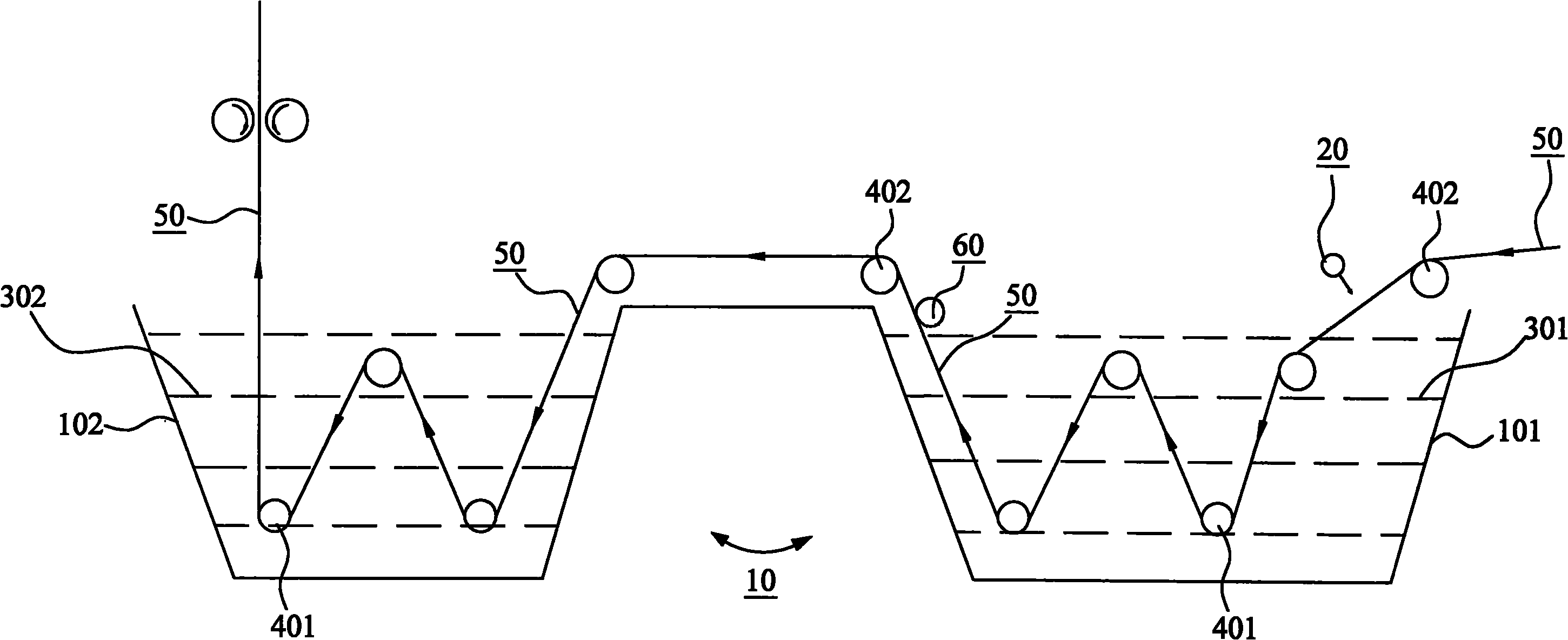

[0012] Please refer to figure 1 As shown, a device for continuously infiltrating the reinforcing material and resin glue includes an infiltration cylinder 10 and a high-pressure glue spray gun 20, wherein:

[0013] The soaking cylinder 10 is provided with two arrays of the first gluing tank 101 and the second gluing tank 102, the viscosity of the resin glue 301 housed in the first gluing tank 101 is lower than that of the second gluing tank 102. The viscosity of the installed resin glue 302; the first guide roller 401 and the second guide roller 402 are respectively arranged inside and outside the first glue tank 101 and the second glue tank 102, and the reinforcing material 50 is wound around the first guide roller 402 On a guide roller 401 and a second guide roller 402, the high-pressure glue spray gun 20 is arranged above the first gluing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com