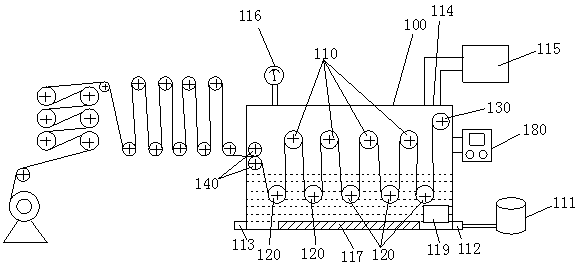

Dyeing apparatus and dyeing method

A dyeing device and dyeing method technology, applied in the field of textile printing and dyeing, can solve the problems of high cost of yarn dyeing device, long yarn production process, large number of dyeing tanks, etc., so as to increase the sufficient soaking time, improve the utilization rate, and reduce the storage capacity. The effect of the barrel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

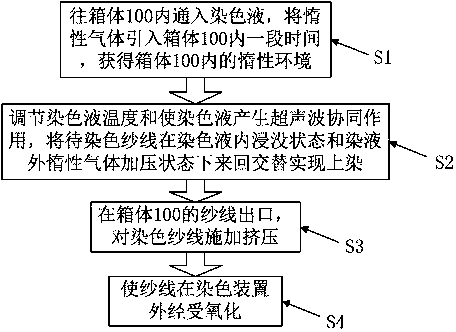

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1: When the temperature of the dyeing solution is 50°C, the amount of nitrogen in the box 100 is 2m 3 , the transmission speed of the yarn to be dyed is 30 m / min, and the K / S value of the fabric woven into a fabric after the yarn is dyed is measured to be 15.89.

Embodiment 2

[0066] Embodiment 2: When the temperature of the dyeing solution is 50°C, the amount of nitrogen in the box 100 is 5m 3 , the transmission speed of the yarn to be dyed is 30 m / min, and the K / S value of the fabric woven into a fabric after the yarn is dyed is measured to be 16.31.

Embodiment 3

[0067] Embodiment 3: When the temperature of the dyeing solution is 50°C, the amount of nitrogen in the box 100 is 2m 3 , the transmission speed of the yarn to be dyed is 30 m / min, the power of the ultrasonic device 119 is 4000W, and the measured K / S value of the fabric woven into a fabric after dyeing the yarn is 16.29.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com