Lithium ion battery pole piece and preparation method thereof

A lithium-ion battery and pole piece technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of rising battery manufacturing costs and declining electrical performance, and achieve short soaking time, reduced pressure, The effect of high craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

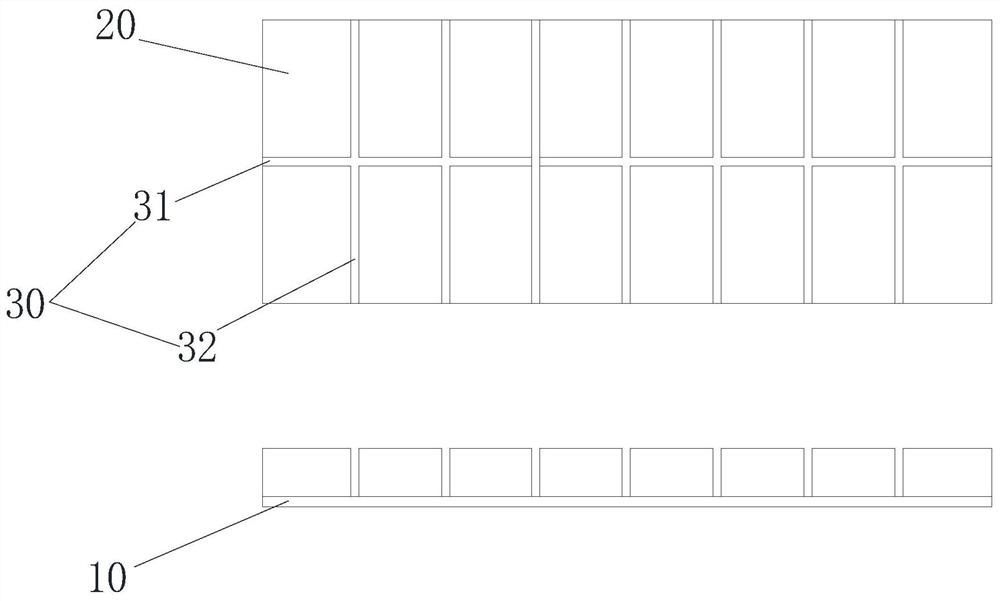

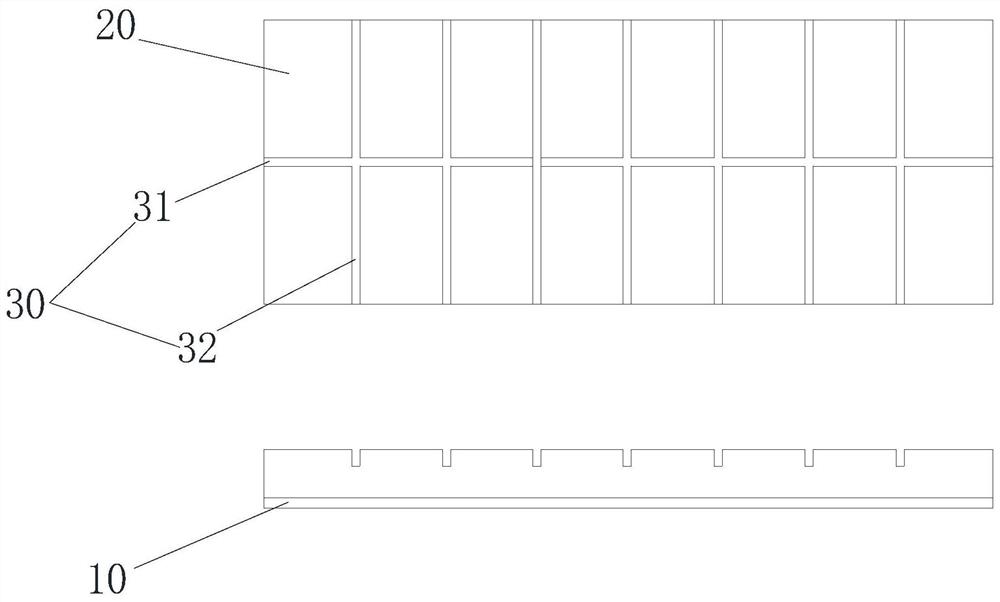

[0029] See figure 2 , the present invention has a lithium-ion battery pole piece, including a current collector 10, an active material layer 20 coated on the surface of the current collector 10, and an electrolyte immersion channel 30 distributed on the active material layer 20; the electrolyte immersion channel 30 includes at least one transverse wetting channel 31 and at least one longitudinal wetting channel 32 perpendicular to the transverse wetting channel 31 .

[0030] More specifically in this embodiment, the thickness of the active material layer 20 is 60 μm˜100 μm. The active material layer 20 is made of lithium iron phosphate, conductive carbon black, and binder PVDF uniformly mixed and coated on the current collector 10 .

[0031] More specifically in this embodiment, the active material layer 20 is made of lithium iron phosphate, conductive carbon black, binder PVDF and solvent NMP uniformly mixed and coated on the current collector 10 .

[0032] In this embodim...

Embodiment 2

[0034] A method for preparing lithium-ion battery pole pieces, comprising the following steps

[0035] The first step is to mix the following four active materials lithium iron phosphate, conductive carbon black, binder PVDF and solvent NMP or the following three active materials lithium iron phosphate, conductive carbon black and binder PVDF to make active material slurry material;

[0036] In the second step, the active material slurry is coated on the current collector 10 by intermittent coating or uniform coating to form an active material layer 20, and dried and rolled at 120°C to a thickness specified by the process;

[0037] In the third step, the active material layer 20 formed by uniform coating in the second step is laser-melted to form the electrolyte infiltration channel 30 .

[0038] More specifically in this embodiment, the intermittent coating method can be realized by coating setup or 3D printing. The active material slurry used in the 3D printing is prepared...

Embodiment 3

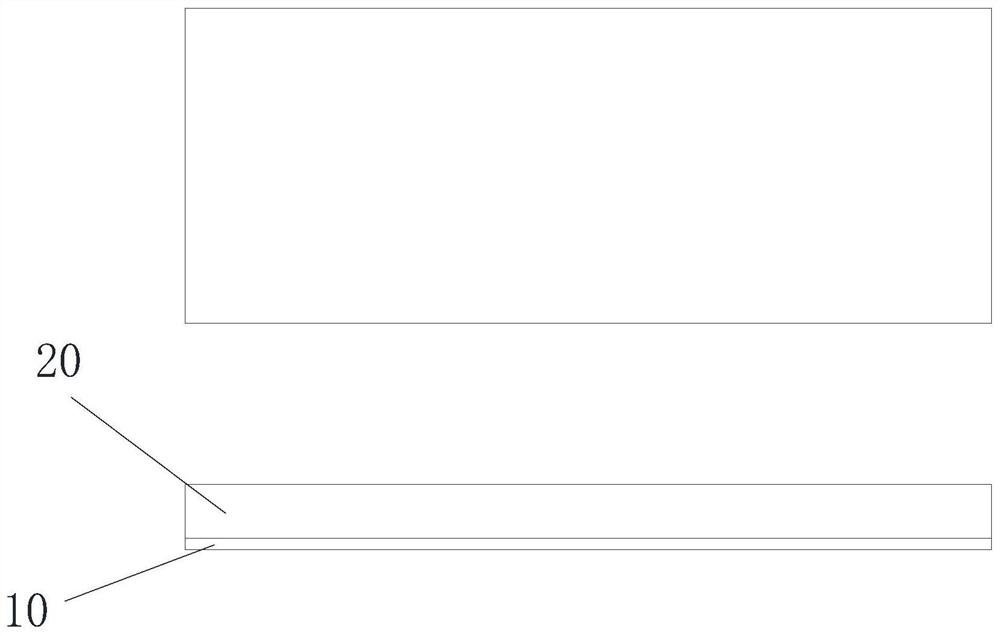

[0040] See figure 1 , the first step, the active material lithium iron phosphate, conductive carbon black, binder PVDF and solvent NMP are evenly mixed to make a slurry;

[0041] In the second step, a coating machine is used to uniformly coat the active material slurry on the current collector 10 to form an active material layer 20;

[0042] The second step is to dry at 120° C. and roll the active material layer 20 of the pole piece to a thickness of 70 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com