Formation method of lithium ion battery, and lithium ion battery

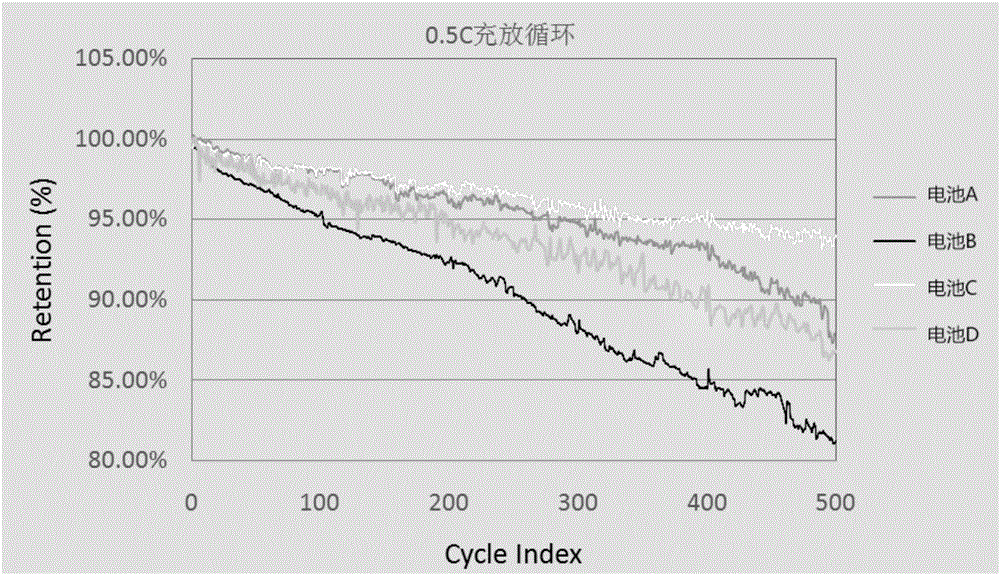

A lithium-ion battery, a technology of a formation method, which is applied in the field of lithium-ion batteries and the formation of lithium-ion batteries, and can solve the problems of poor battery cycle performance, poor battery flatness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

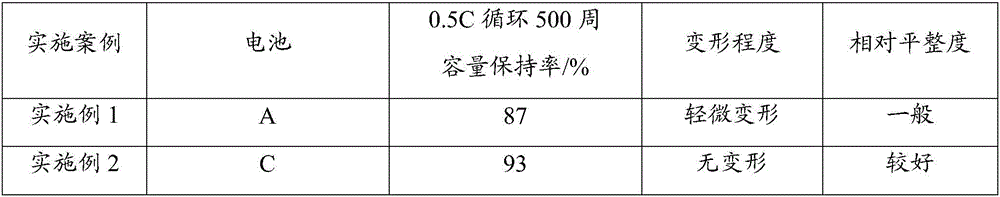

Embodiment 1

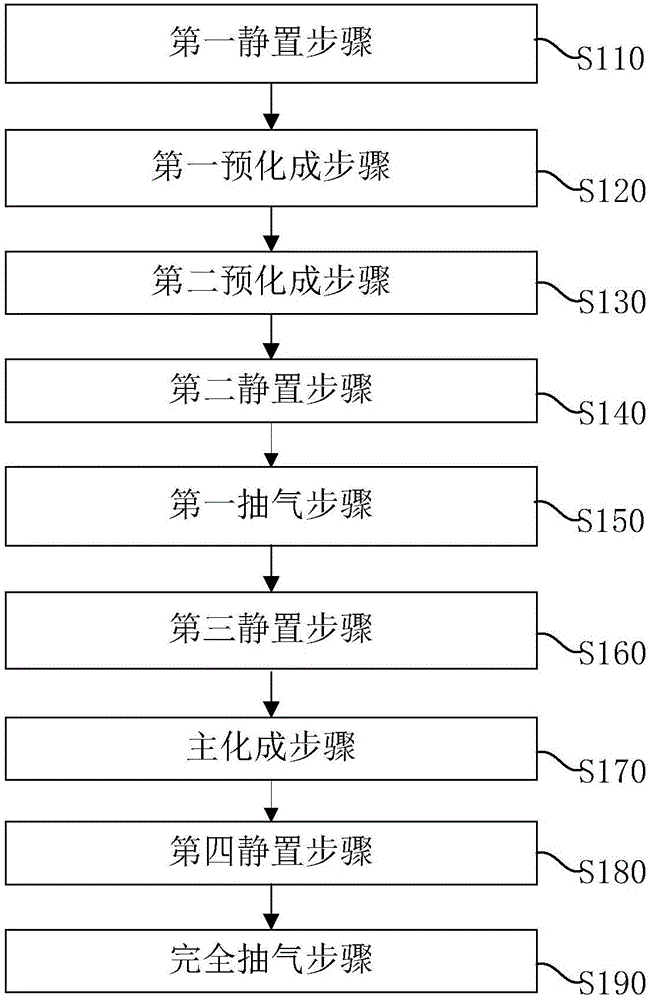

[0096] Lithium-ion battery formation method, comprises the following steps:

[0097] 1) Standing at room temperature: After injecting the electrolyte, the lithium cobalt oxide battery was left standing at 40°C for 30 hours, and then at room temperature for 12 hours.

[0098] 2) Preformation: 1.2kgf / cm force on the front and back of the battery 2 , and the airbag belt avoids the pressure equipment, and is charged according to the following current:

[0099] First charge at 0.01C constant current for 30 minutes, and the voltage is 3850mV.

[0100] Then charge at 0.02C constant current for 40min, the voltage is 3850mV.

[0101] Then charge at a constant current of 0.05C for 70 minutes, and the voltage is 3850mV.

[0102] Then charge at 0.1C constant current for 150min, and the voltage is 4000mV.

[0103] 3) Standing at high temperature: the battery was left standing at 40°C for 16 hours.

[0104] 4) After vacuum pre-extraction, under the pressure of 1.4kgf / cm 2 , Stand at a...

Embodiment 2

[0111] Lithium-ion battery formation method, comprises the following steps:

[0112] 1) Standing at room temperature: After liquid injection, the lithium cobalt oxide battery was left standing at 40°C for 30 hours, and then at room temperature for 12 hours.

[0113] 2) Preformation: the force on the front and back of the battery is 1.2kgf / cm 2 , and the airbag belt avoids the pressure equipment. And charge according to the following current:

[0114] First charge at 0.01C constant current for 30 minutes, and the voltage is 3850mV.

[0115] Then charge at 0.02C constant current for 40min, the voltage is 3850mV.

[0116] Then charge at a constant current of 0.05C for 70 minutes, and the voltage is 3850mV.

[0117] Then charge at 0.1C constant current for 150min, and the voltage is 4000mV.

[0118] 3) Standing at high temperature: the battery was left standing at 40°C for 16 hours.

[0119] 4) Pre-extraction: Under vacuum, extract part of the gas inside the battery.

[012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com