Technology for reducing waste incineration fly ash via water logging pretreatment

A waste incineration fly ash and waste incineration technology, applied to the removal of solid waste, etc., can solve the problems of potential hazards in resource utilization of slag, unrealized purification and removal of heavy metals, and limited processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

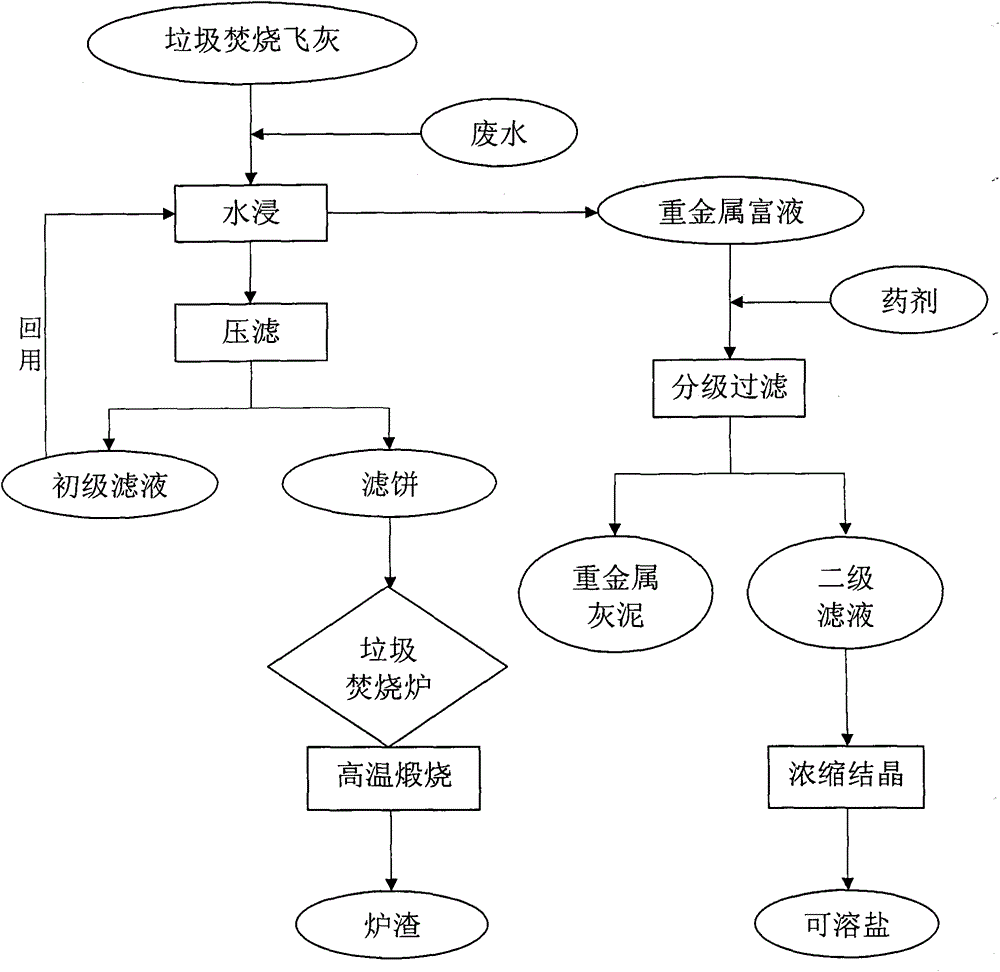

Method used

Image

Examples

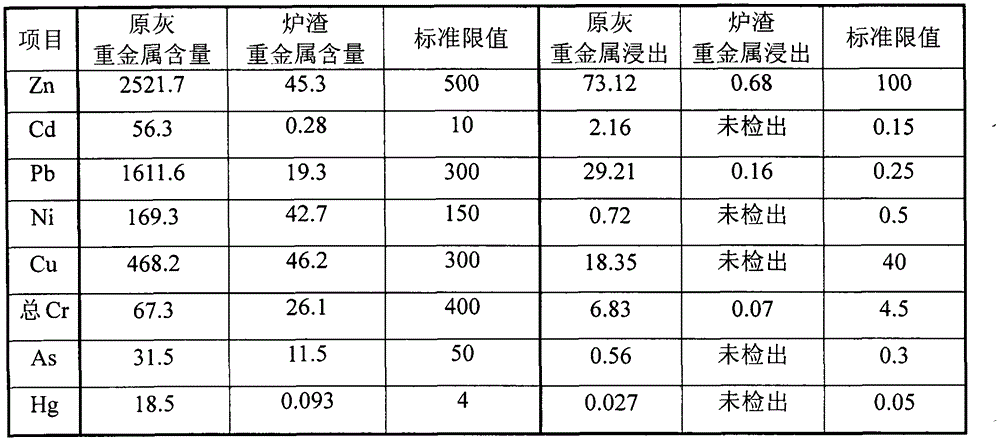

Embodiment 1

[0024] (1) Mix the waste incineration fly ash with a salt content of 22% and the leachate uniformly in the soaking tank. The ratio of the waste incineration fly ash to the leachate is 1:1, soak for 1.5 days, and stir regularly;

[0025] (2) After the ash-water mixture is formed by pressure filtration, the filter cake is sent to a garbage incinerator for high-temperature calcination. The sintering temperature is 900°C. The captured secondary fly ash is 2.2% of the original fly ash. The calcined fly ash is finally The furnace body is discharged in the form of slag, and the primary filtrate is returned to step (1) for reuse, and after being reused 5 times, it is discharged as a heavy metal rich liquid out of the circulating washing system;

[0026] (3) The heavy metal rich liquid is added with heavy metal trapping agent to separate heavy metals from the water body in the form of flocculated sediment, and then the heavy metal mortar is separated from the water body through microfiltrati...

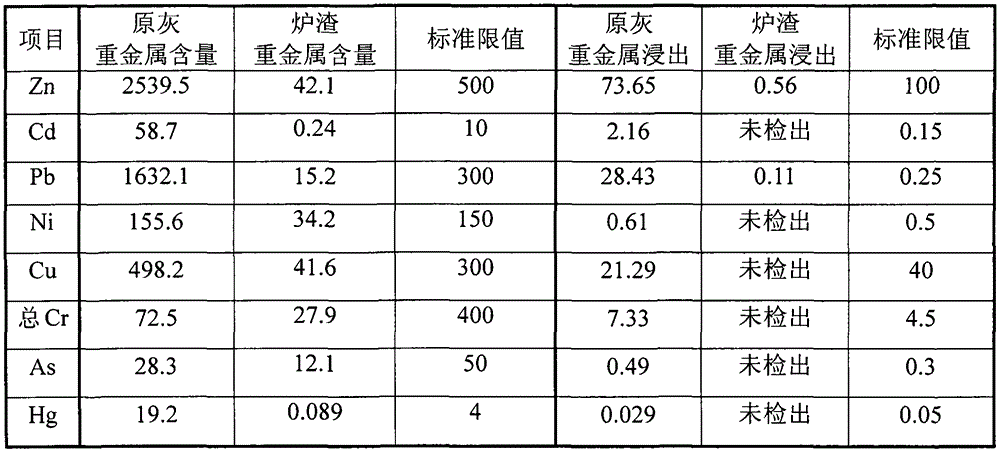

Embodiment 2

[0032] (1) Mix the waste incineration fly ash with a salt content of 25.3% and the MBR effluent evenly in the soaking tank. The ratio of waste incineration fly ash and MBR effluent is 1:2, soak for 2 days, and stir regularly;

[0033] (2) After the ash-water mixture is formed by pressure filtration, the filter cake is sent to the garbage incinerator for high-temperature calcination. The sintering temperature is 950℃. The captured secondary fly ash is 2.5% of the original fly ash. The furnace body is discharged in the form of slag, and the primary filtrate is returned to step (1) for reuse, and after being reused 4 times, it is discharged out of the circulating washing system as a heavy metal rich liquid;

[0034] (3) The heavy metal rich liquid is added with a coagulant to precipitate heavy metals from the water body in the form of flocculated sediments, and then the heavy metal mortar is separated from the water body through ultrafiltration and nanofiltration, and the heavy metal m...

Embodiment 3

[0040] (1) Mix the waste incineration fly ash with a salt content of 27.2% and the RO concentrated water evenly in the soaking tank. The ratio of the waste incineration fly ash and RO concentrated water is 1:3, soak for 3 days, and stir regularly;

[0041] (2) After the ash-water mixture is formed by pressure filtration, the filter cake is sent to the garbage incinerator for high-temperature calcination. The sintering temperature is 1000°C. The captured secondary fly ash is 2.9% of the original fly ash. The calcined fly ash is finally The furnace body is discharged in the form of slag, and the primary filtrate is returned to step (1) for reuse, and after being reused 3 times, it is discharged as a heavy metal rich liquid out of the circulating washing system;

[0042] (3) The heavy metal rich liquid is added with heavy metal trapping agent to precipitate heavy metals from the water body in the form of flocculated sediment, and then the heavy metal mortar is separated from the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com