Ultrasonic wave roller bottle washing machine

A technology of ultrasonic wave and bottle washing machine, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., which can solve the problems of increasing labor intensity and labor costs, difficulty in cleaning residues, and reducing economic efficiency of enterprises, etc. problems, to achieve the effect of saving manpower and labor time, improving cleaning rate and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

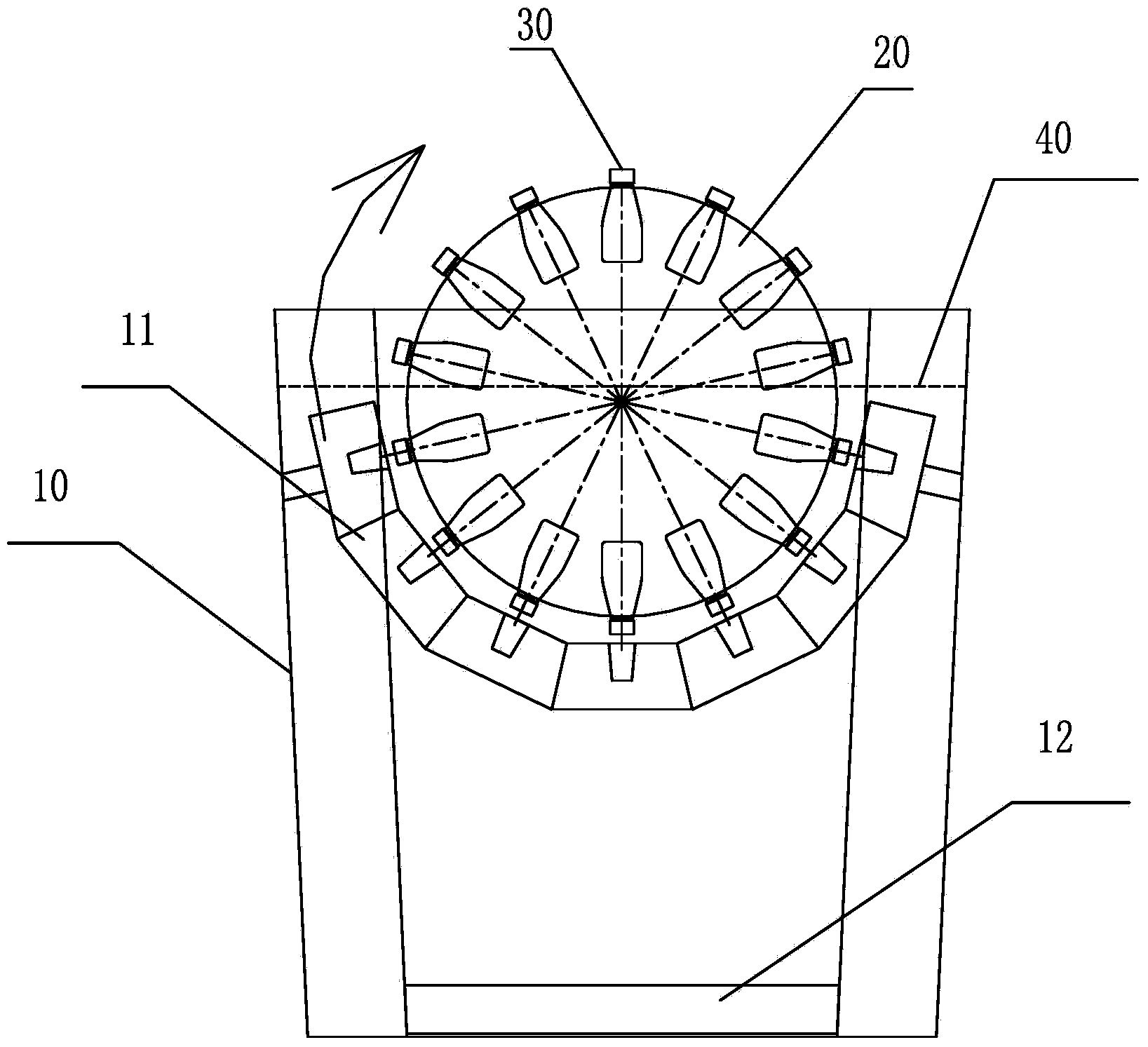

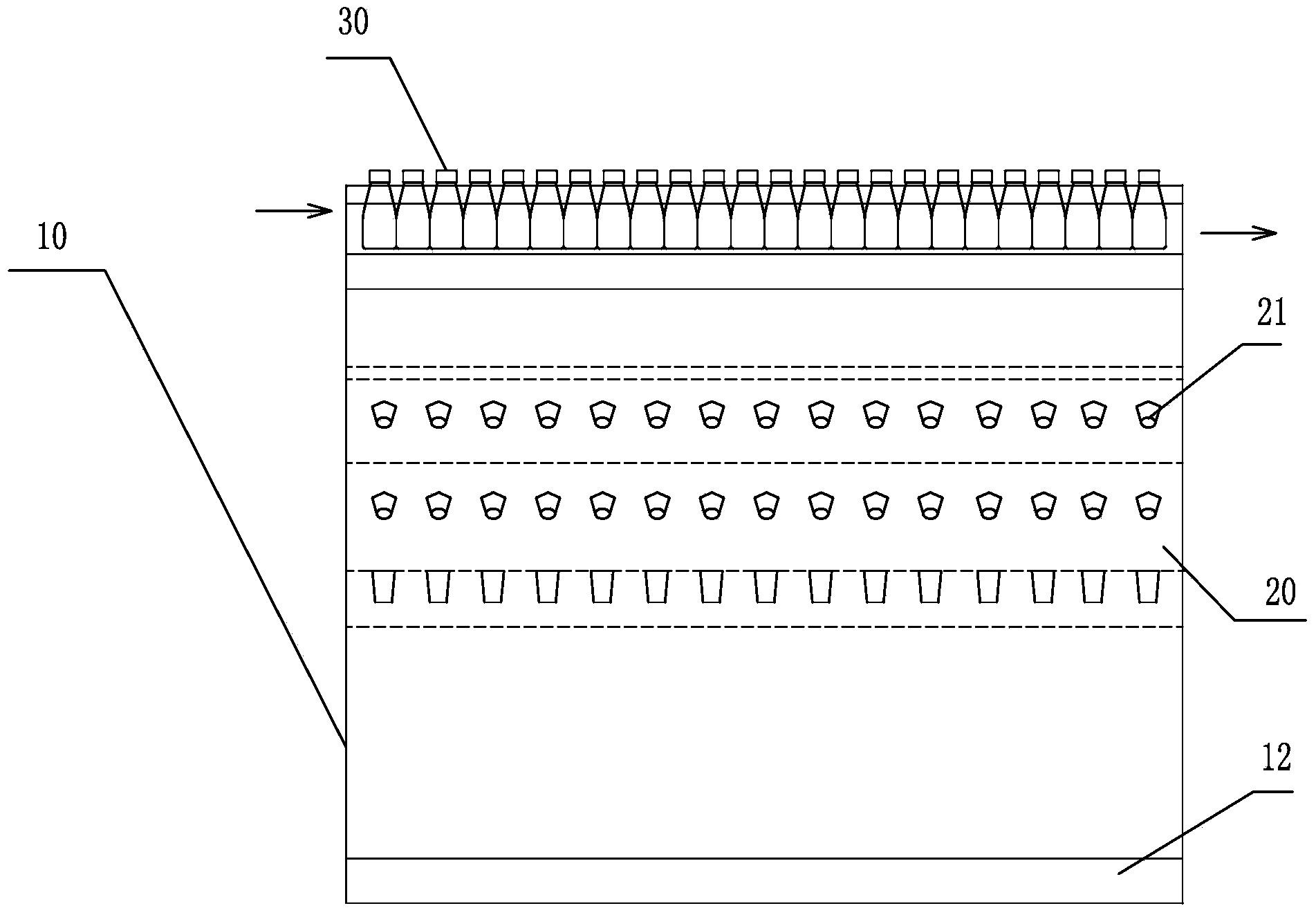

[0020] see figure 1 and figure 2 , the present implementation is to provide a cleaning machine for cleaning bottles of a drum type, i.e. an ultrasonic drum bottle washing machine, which includes a soaking tank 10 filled with a cleaning solution 40 and a drum bottle carrier 20 arranged in the soaking tank 10 and driven The power unit for the rotation of the roller bottle carrier 20. What the roller bottle carrier 20 of this embodiment adopts is the anti-bending combination roller type bottle carrier of the all-plastic bottle box, and is evenly provided with on the circumferential surface of the roller type bottle carrier rack 21 for loading the bottle to be cleaned , What carry bottle groove 21 adopted is the plastic bottle box that is adapted w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com