Flow uranium leaching process

A process and leaching technology, applied in the field of uranium smelting, can solve problems such as increasing production costs, precipitation clogging, and affecting the recovery of uranium resources, and achieve the effects of increased production efficiency, reduced material costs, and significant leaching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

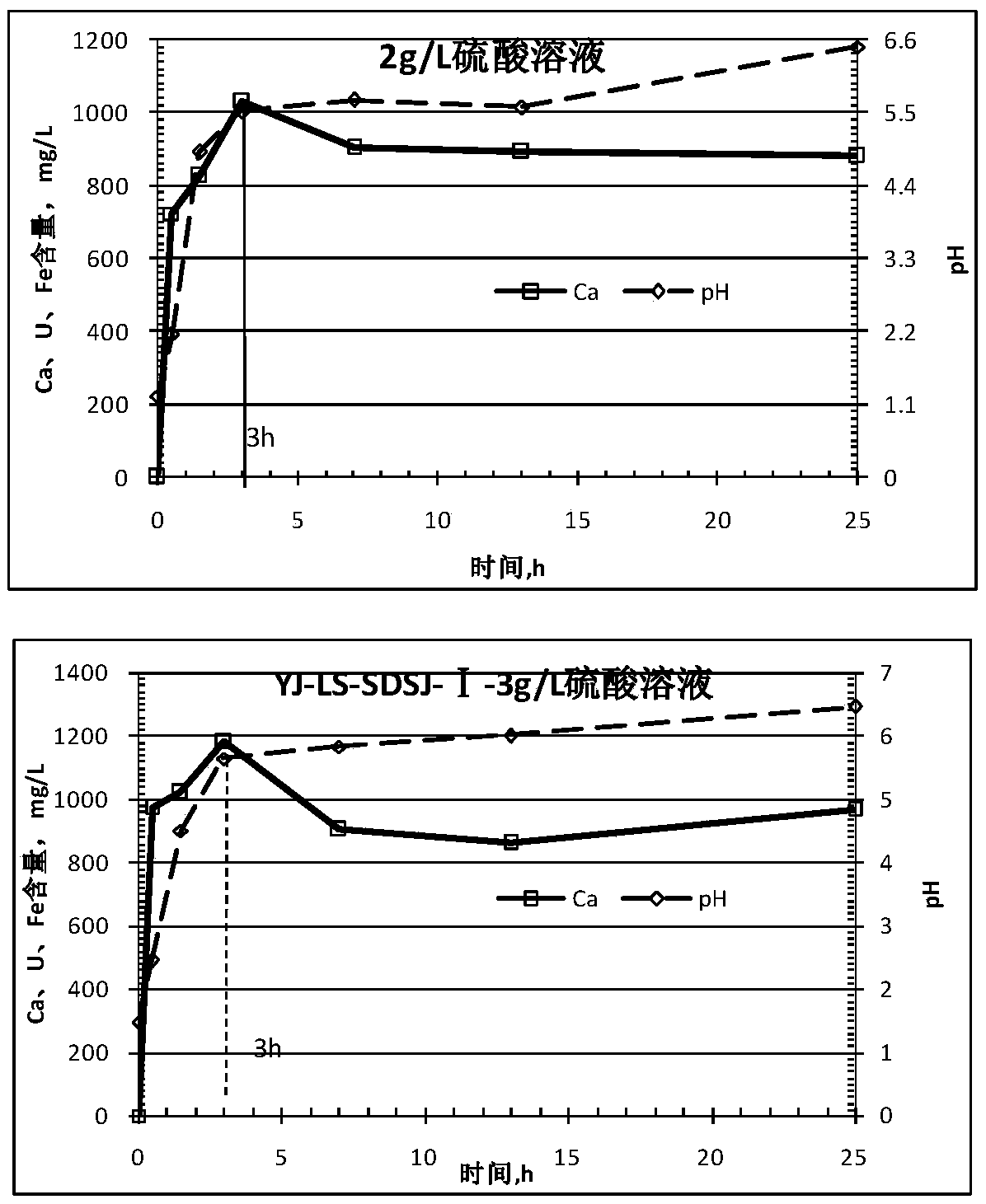

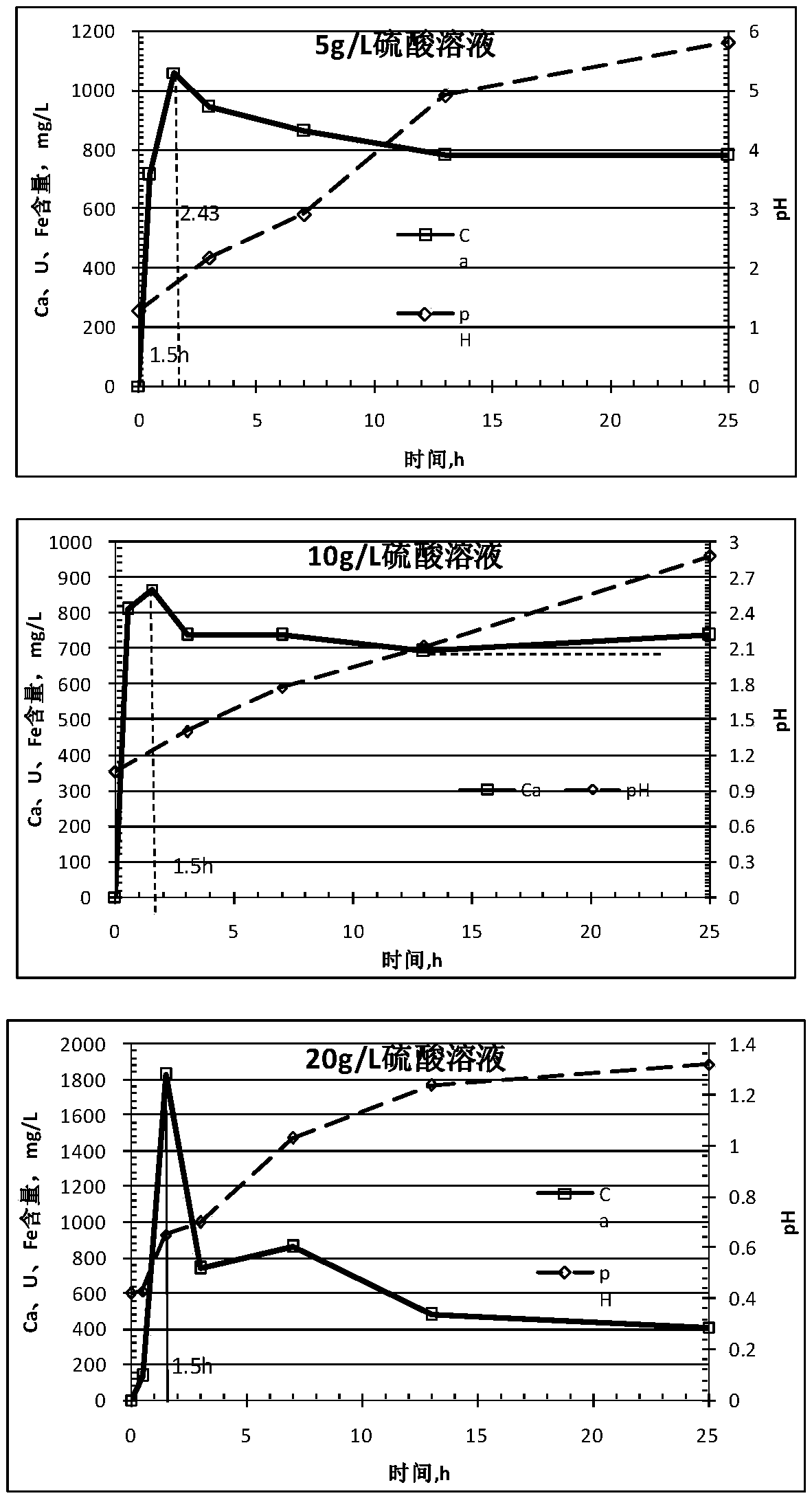

[0058] Alkaline cloud uranium ore is a very acid-consuming and difficult to leach ore. The uranium grade is low, 0.1-0.12%, but the calcium carbonate content is high, more than 4-5%. In September 2015, two flow uranium leaching process tests were carried out using alkaline cloud-bound uranium ore, Example 1 and Example 2, and the two examples were YJLS7LD4 and YJLS8LD5 respectively.

[0059] 1. Determination of three hydrogeochemical parameters

[0060] 1. Reaction condition boundary value

[0061] When the reaction free energy of hydrogeochemical action is set to zero, and other reaction conditions related to the action are set as constant values, the ideal value of another studied reaction condition calculated according to the principle of thermodynamics is called Reaction condition boundary value.

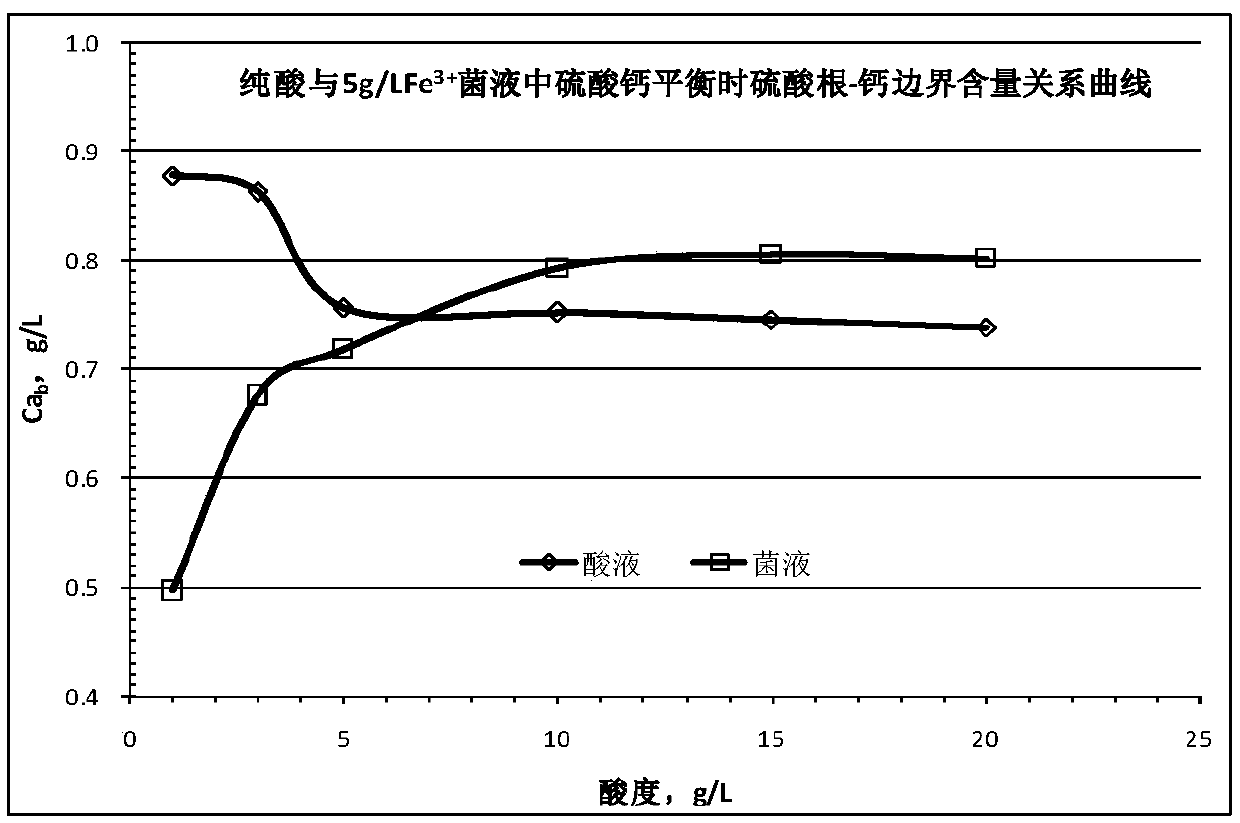

[0062] In sulfuric acid medium, the reaction conditions related to calcium sulfate precipitation include sulfate radical and calcium ion, but the decisive factor is calcium io...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com