A kind of flow leaching uranium system and flow leaching uranium process

A kind of leaching, part of the technology, applied in the field of uranium smelting, can solve the problems of long cycle, difficult to adapt to demand, affecting the reliable supply of uranium resources and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

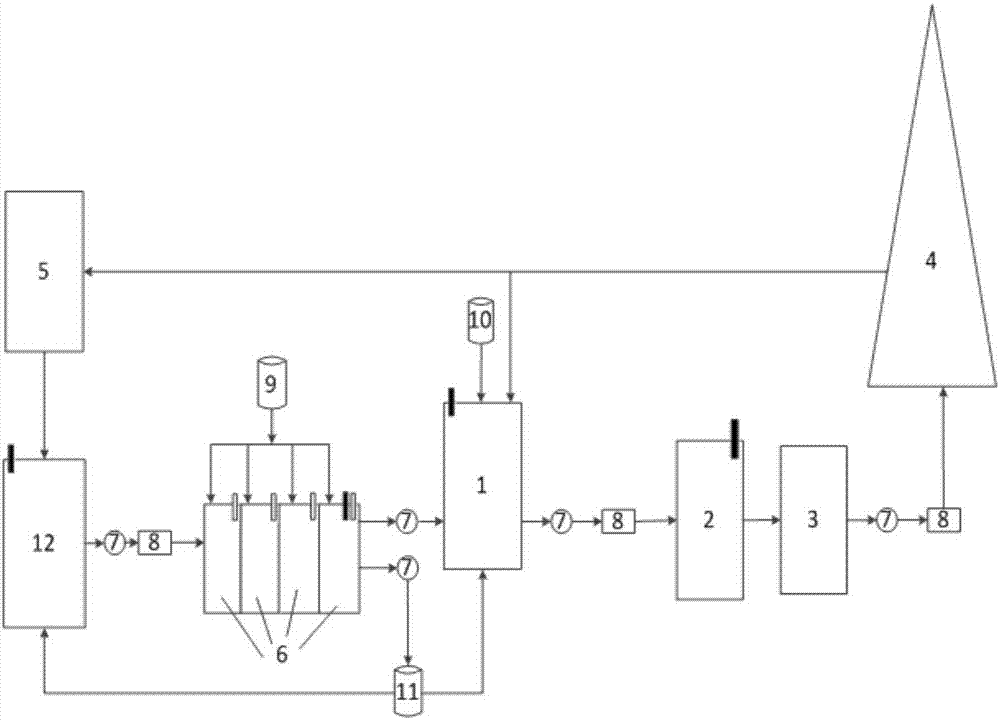

[0069] A mobile uranium leaching system, such as figure 1 -3 shows that it includes a liquid distribution tank 1, a flow uranium immersion tank 2, a stock solution tank 3, an adsorption tower 4, a tail liquid tank 5, a culture solution distribution tank 12, an oxidation tank 6, a liquid pump 7, a flow meter 8 and connected pipes.

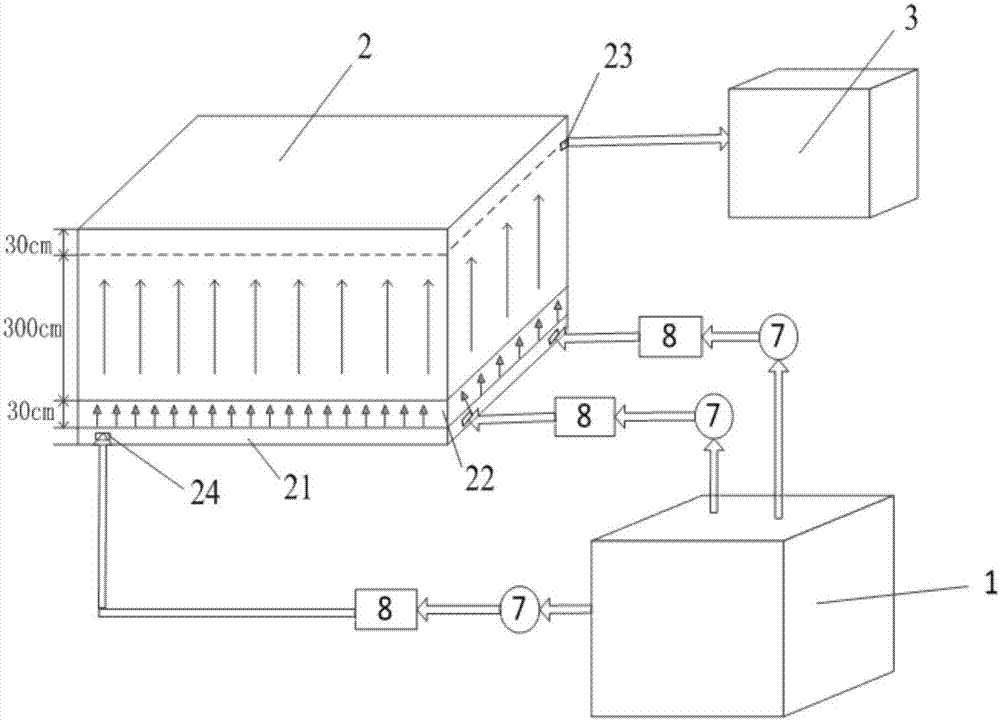

[0070] The leaching solution of the flowing uranium leaching pool 2 enters from the bottom and exits from the top. The height of the flowing uranium leaching pool is 360 centimeters, and the liquid outlet 23 is set at a height of 330 centimeters in the flowing uranium leaching pool. The liquid inlet system includes a leaching solution inlet 24, a cloth The liquid pipe 22 and the pebble layer, four immersion liquid inlets 24 are evenly arranged at the bottom of the pool body, in order to maintain the balance of the liquid inlet pressure, the immersion liquid inlet 24 is externally connected to the liquid inlet pipe 21, internally connected to the liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com