Cigarette tar-reducing harm-reducing process and supercritical extraction device for tobacco shred or tobacco leaves

A treatment process and technology of supercritical fluid, applied in the treatment of tobacco, tobacco, application, etc., can solve the problems of influence, scorched and bitter smell of cut tobacco, low extraction efficiency of cut tobacco, etc., to reduce release, improve safety, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

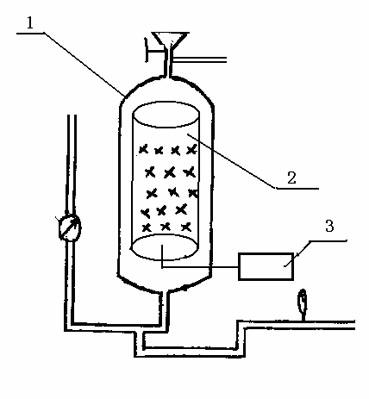

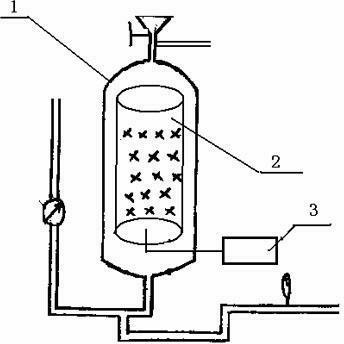

Image

Examples

Embodiment 1

[0030] Place the cage containing 200 Kg of shredded cigarette tobacco in a closed extraction container, and inject liquid CO into the container. 2 As the extraction solvent, add absolute ethanol as an entrainer, adjust the temperature of the extraction kettle to 30°C, adjust the extraction pressure to 20Mpa, completely immerse the shredded cigarette tobacco, adjust the rotation speed of the cage to 40r / min, and rotate the extraction time for 20min. After the extraction, During the process of solvent removal, the temperature in the extraction container is kept at 20°C, the liquid solvent is drawn out from the lower part of the container, and the vaporized solvent is drawn out from the upper part of the container. After the extraction is completed, the cut tobacco is processed in a 150KW microwave for 220s Solvents in tobacco leaves.

Embodiment 2

[0032] Place the cage containing 200 Kg of tobacco leaves in a closed extraction container, and inject liquid CO into the container. 2 As the extraction solvent, add absolute ethanol as an entrainer, adjust the temperature of the extraction kettle to 30°C, adjust the extraction pressure to 20Mpa, completely immerse the finished tobacco leaves, adjust the rotation speed of the cage to 40r / min, and rotate the extraction time for 20min. After the extraction, The leaves were placed in hot air at 100°C for 10 minutes to remove the solvent in the tobacco leaves.

Embodiment 3

[0034] Put the cage containing 200 Kg of finished tobacco leaves in a closed extraction container, inject liquid dimethyl ether into the container as the extraction solvent, and inject acetone as an entrainer, adjust the temperature of the extraction kettle to 40°C, and adjust the extraction pressure to 30Mpa , completely immerse the finished tobacco leaves, adjust the rotating speed of the cage to 20r / min, rotate the extraction time for 25min, after the extraction is completed, extract the vaporized solvent from the upper part of the container, take out the finished tobacco leaves from the container as a whole, and place them in a 200KW microwave for processing 150s to remove the solvent in the tobacco leaves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com