Secondary molding sandwich EVA foaming wear-resistant sports sole and manufacture method thereof

A technology of secondary molding and manufacturing method, which is applied in the direction of shoe soles, footwear, footwear, etc.

Active Publication Date: 2015-08-26

泉州泰亚鞋业有限公司

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

And there is no report so far about the secondary molded sandwich EVA foaming wear-resistant sports shoes sole

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

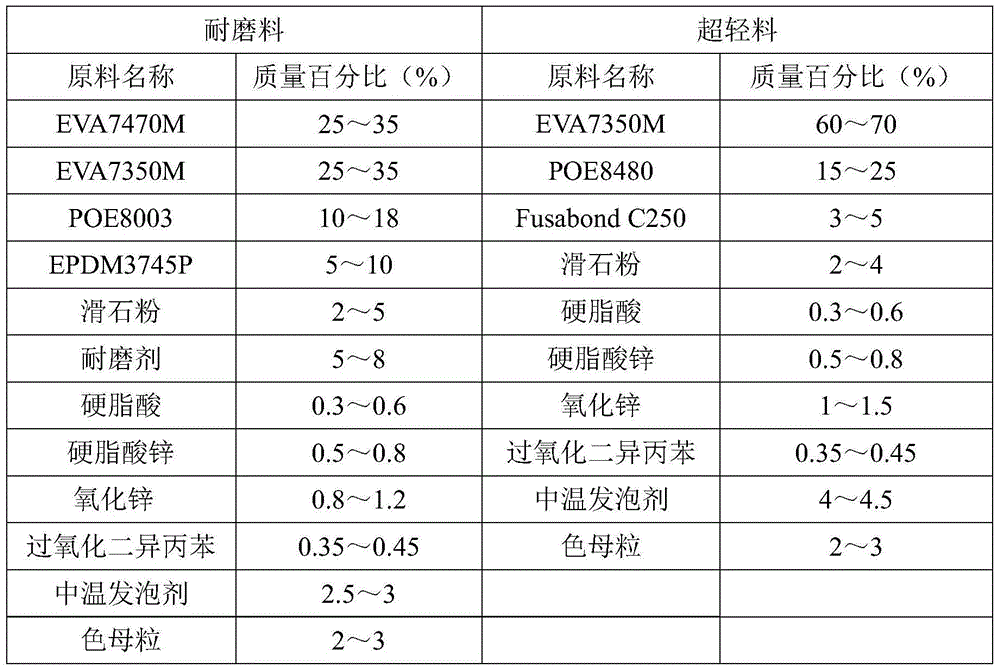

[0035] Example 1 The formula of Example 1 is shown in Table 2.

[0036] Table 2

[0037]

Embodiment 2

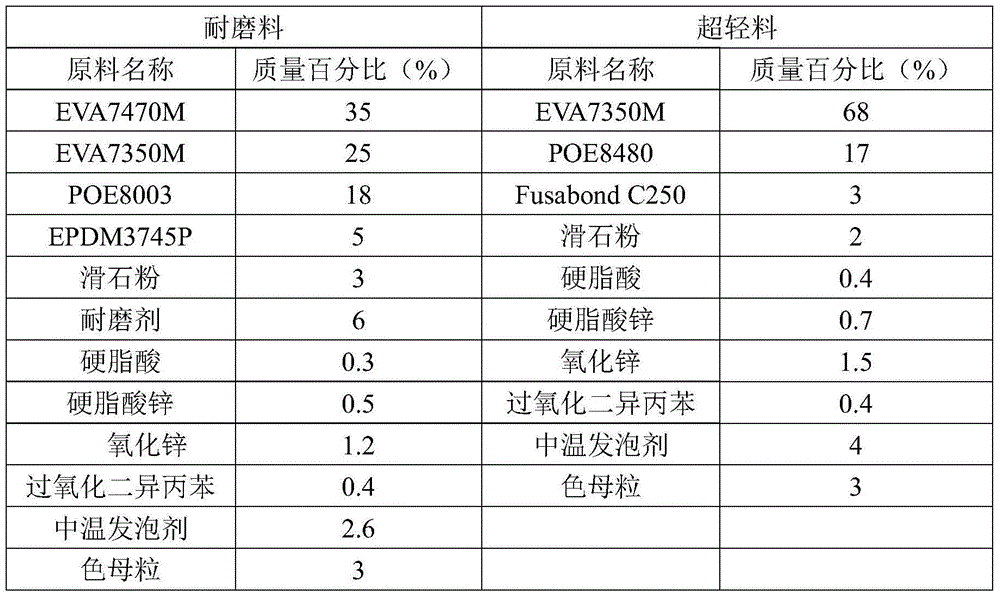

[0038] Example 2 The formulation of Example 2 is shown in Table 3.

[0039] table 3

[0040]

Embodiment 3

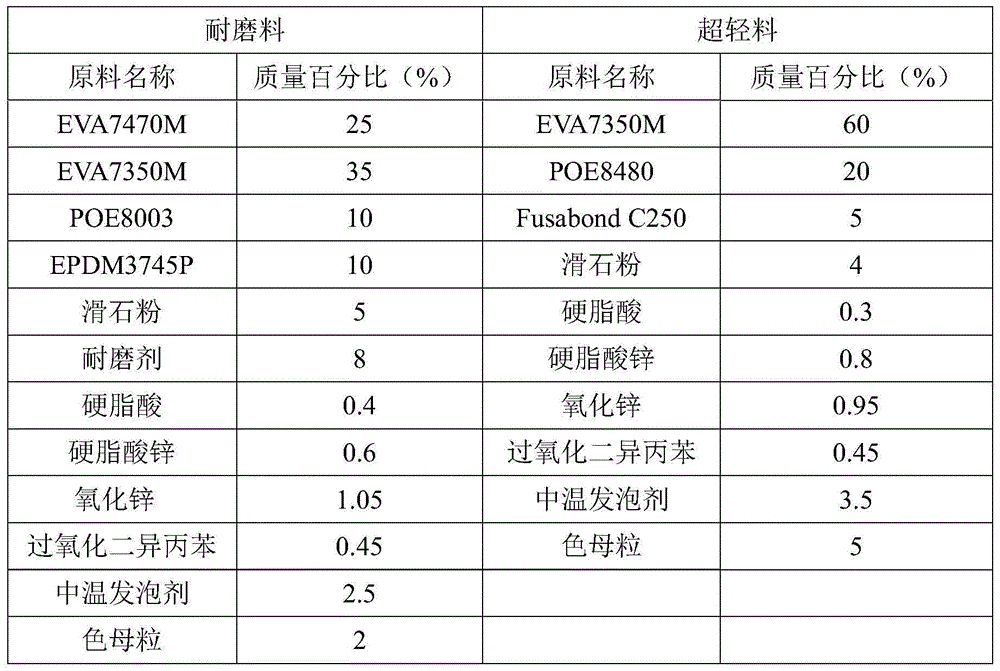

[0041] Example 3 The formulation of Example 3 is shown in Table 4.

[0042] Table 4

[0043]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention discloses a secondary molding sandwich EVA foaming wear-resistant sports sole and a manufacture method thereof, and relates to a sole. The secondary molding sandwich EVA foaming wear-resistant sports sole has an upper wear-resistant layer and a lower wear-resistant layer; and a super light material layer is set between the upper wear-resistant layer and the lower wear-resistant layer. The raw material of the super light material layer comprises ethane-vinyl acetate copolymer, ethane- octene copolymer, terpolymer EP rubber, powdered steatile, wear-resisting agent, eleaostearic acid, zine stearate, zinc oxide, dicumyl peroxide, azodicarbonamide and color master batch. The raw material of the super light material layer comprises ethane-vinyl acetate copolymer, ethane- octene copolymer, ethane-acrylic acid copolymer, powdered steatile, eleaostearic acid, zine stearate, zinc oxide, dicumyl peroxide, azodicarbonamide and color master batch. The product is manufactured by secondary molding, therefore the product is wear-resistant and light.

Description

technical field [0001] The invention relates to a shoe sole, in particular to a secondary molded sandwich EVA foamed wear-resistant sports shoe sole and a manufacturing method thereof. The ultra-light material and the wear-resistant material are foamed together to reduce the link of combining the two materials with glue. At the same time, its sole is light and wear-resistant. Background technique [0002] With the development of Chinese sports brands, more and more functional shoe materials have entered our field of vision, making Chinese shoe materials, especially sports shoe materials, at the forefront of brand development. Before 2007, domestic sports brands experienced the era of male models who only paid attention to appearance. A good-looking sole can be used by everyone; from 2007 to 2012, with the construction of design teams of major brands, male models gradually withdrew from the stage of history. The private model with independent intellectual property rights of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A43B13/12A43B13/04C08L23/08C08L23/16C08K13/02C08K3/34C08K5/09C08K5/098C08K3/22C08K5/14C08J9/10B29D35/14

Inventor 陈永华林松柏

Owner 泉州泰亚鞋业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com