High-hardness and erasing-resistant hardening coating liquid and hardened film

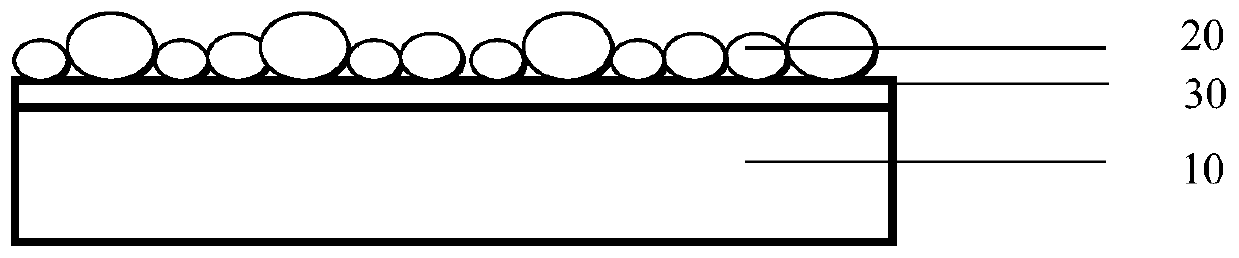

A technology of coating liquid and hardened film, applied in the field of hardened layer coating liquid that is resistant to erasing and writing, and high hardness, it can solve the problem that the protective film cannot have both high hardness and resistance to erasing and writing, and achieve high wear resistance and high hardness. The effect of transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

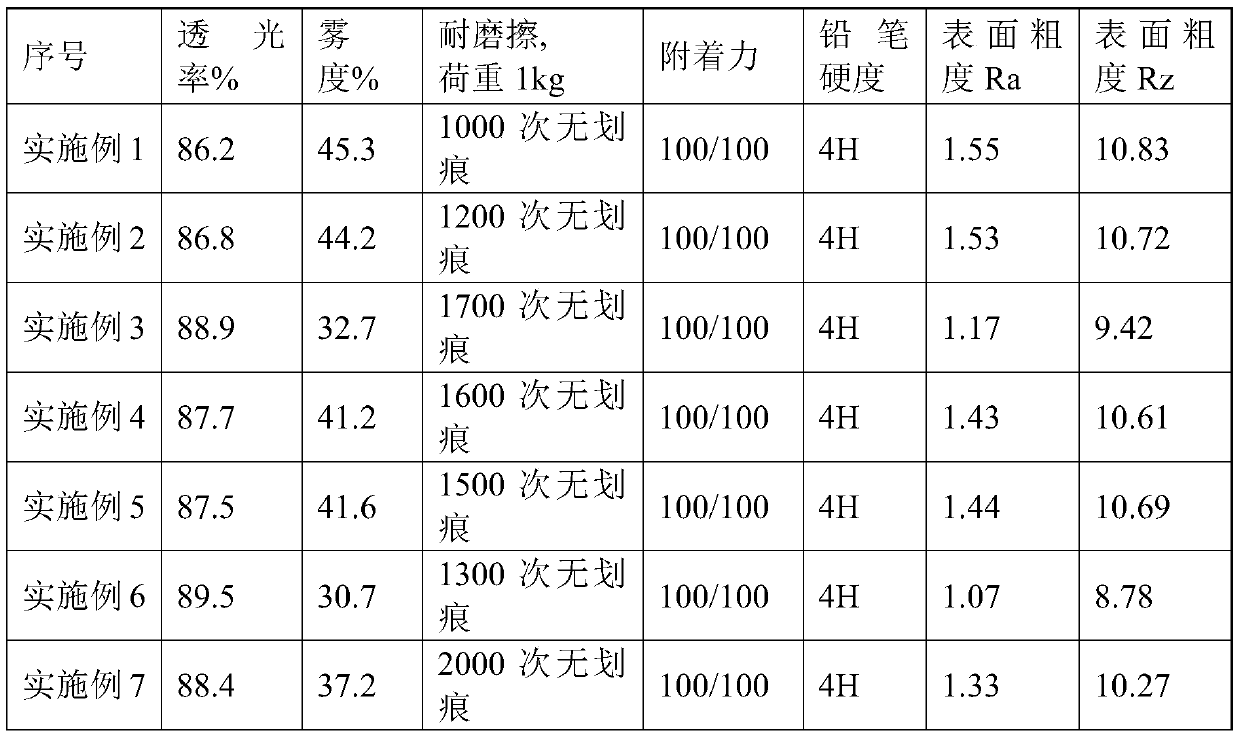

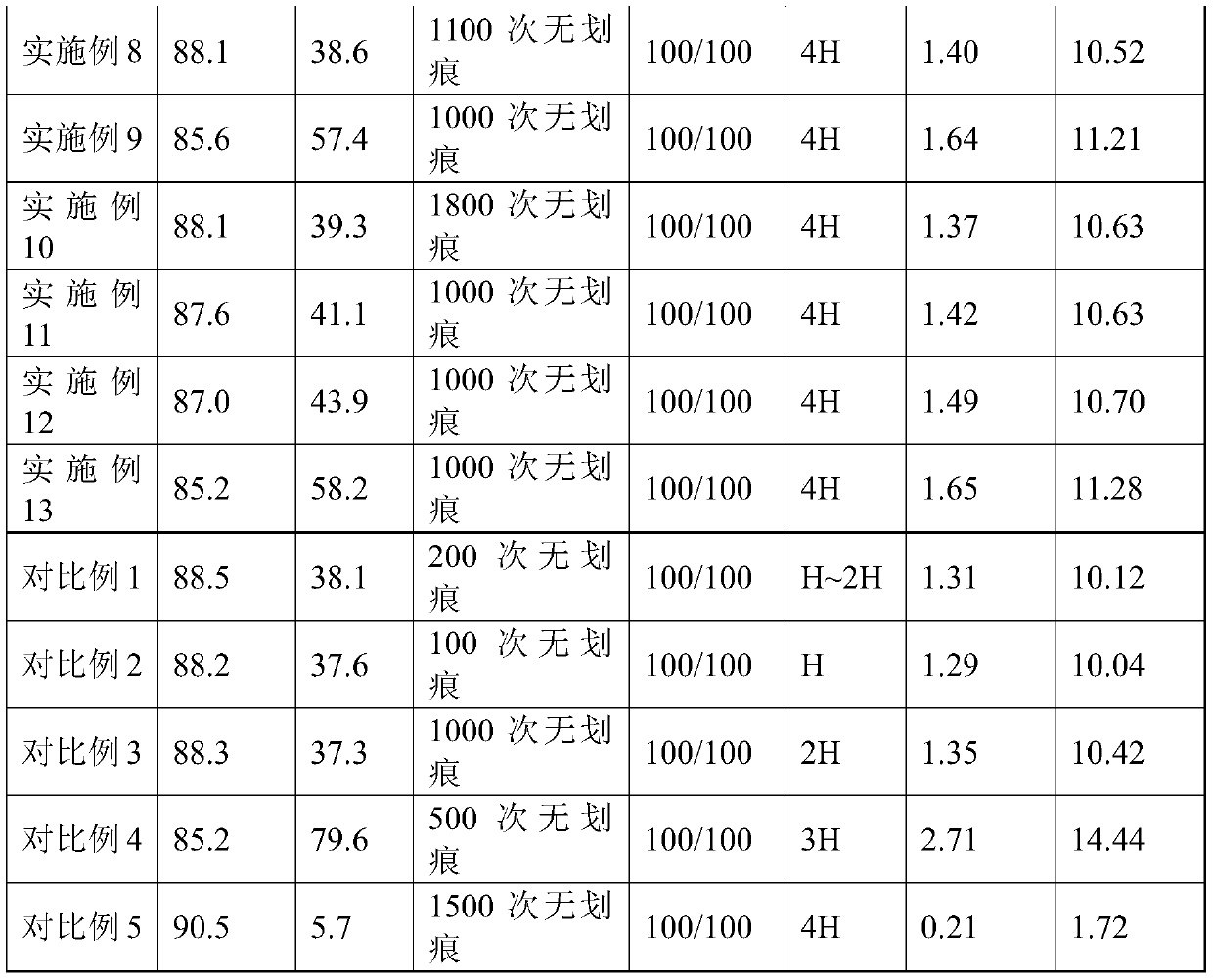

[0077] The invention provides a coating solution for a hardened layer, which comprises 30% acrylate prepolymer, 40% acrylate monomer, 25.6% organic particles (PMMA), 4% photoinitiator, 0.4% auxiliary agent, said percentage content is weight percentage content.

[0078] The preparation method of the hardening solution provided in this embodiment includes:

[0079] 25% nine-official urethane acrylic resin oligomer, 5% six-official urethane acrylic resin oligomer, 40% difunctional acrylate monomer, 25.6% polymethyl methacrylate particles, 4% photoinitiator , 0.4% leveling agent. Disperse the main resin in an organic solvent to form a hardening solution with a solid content of 50%. Among them, the nine-functional polyurethane acrylic resin oligomer, the six-functional polyurethane acrylic resin oligomer, and the difunctional acrylate monomer are all provided by Meiyuan Special Chemical Co., Ltd., and the photoinitiator is 184 provided by BASF Co., Ltd. The base methyl acrylate ...

Embodiment 2

[0084] The preparation method of the hardening solution provided in this embodiment includes:

[0085] 20% nine-official urethane acrylic resin oligomer, 26% six-official urethane acrylic resin oligomer, 24.2% difunctional acrylate monomer, 24.3% polymethyl methacrylate particles, 5% photoinitiator , 0.5% leveling agent. Disperse the main resin in an organic solvent to form a hardening solution with a solid content of 45%. Among them, the nine-functional urethane acrylic resin oligomer, the six-functional urethane acrylic resin oligomer, and the difunctional acrylate monomer are all provided by Meiyuan, the photoinitiator is 184 provided by BASF, and the polymethyl methacrylate particles are from the comprehensive research institute. The leveling agent is provided by BYK, and the organic solvent is ethyl acetate.

[0086] Coatings were applied on 125 μm PET substrates.

[0087] The thickness of the formed hardened layer was 24 μm.

[0088] The performance test results of t...

Embodiment 3

[0090] 35% nine-official urethane acrylic resin oligomer, 10% six-official urethane acrylic resin oligomer, 38.3% difunctional acrylate monomer, 13% polymethyl methacrylate particles, 3.5% photoinitiator , 0.2% leveling agent. Disperse the main resin in an organic solvent to form a hardening solution with a solid content of 37%. Among them, the nine-functional urethane acrylic resin oligomer, the six-functional urethane acrylic resin oligomer, and the difunctional acrylate monomer are all provided by Meiyuan, the photoinitiator is 184 provided by BASF, and the polymethyl methacrylate particles are from the comprehensive research institute. The leveling agent is provided by BYK, and the organic solvent is ethyl acetate.

[0091] Coatings were applied on 188 μm PET substrates.

[0092] The thickness of the formed hardened layer was 15 μm.

[0093] The performance test results of the prepared cured film are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com