Casting material for wear-resistant pump block of nuclear power steam turbine and manufacturing method thereof

A steam turbine and wear-resistant pump technology, applied in the field of casting materials, can solve the problems of difficult secondary molding, inclusions on the surface of pores, and the inability of bronze ingots to meet requirements, and achieve the effects of avoiding cracking, reducing porosity, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing a casting material applied to a wear-resistant pump block of a nuclear power steam turbine, comprising the following steps:

[0020] 1), according to the ratio of aluminum: 2.4%, iron: 7.2%, manganese: 1.5%, nickel: 5.5%, copper: the mass percentage of the balance, configure the raw materials, put them in a power frequency electric furnace, and heat them to 1100 degrees , after completely melting and keeping warm;

[0021] 2), add the rare earth element lanthanum or cerium: 1.5%, by mass percentage, in the middle of the alloy solution being kept warm, open the vibrating device and the stirring device, the vibration frequency of the vibrating device is: 10 times / second; the stirring rate of the stirring device is : 150 rpm, stirring time: 5-10 minutes;

[0022] 3) Add 6.5% of titanium boride with a particle size greater than 100 microns to less than 200 microns, by mass percentage, into the alloy solution, and stir again at the same time, the stir...

Embodiment 2

[0027] Embodiment 2 is different from Embodiment 1 only in the ratio of raw materials, and is the same in other respects. Therefore, only the differences will be described below.

[0028] The mass percentage of each component in step 1) is: aluminum: 3.0%, iron: 7.6%, manganese: 2%, nickel: 6%, copper: balance.

[0029] The mass percentage of the rare earth element lanthanum or cerium in step 2) is: 2%.

[0030] The mass percentage of titanium boride in step 3) is: 7%.

[0031] According to the second embodiment, basically the same effect as that of the first embodiment can be achieved.

Embodiment 3

[0033] Embodiment 3 is different from Embodiment 1 and 2 only in the ratio of raw materials, and is the same in other respects. Therefore, only the differences will be described below.

[0034] The mass percent of each component in step 1) is: aluminum: 3.2%, iron: 7.8%, manganese: 2.5%, nickel: 6.5%, copper: balance.

[0035] The mass percentage of the rare earth element lanthanum or cerium in step 2) is: 2.5%.

[0036] The mass percentage of titanium boride in step 3) is: 7.5%.

[0037] According to the third embodiment, basically the same effects as those of the first and second embodiments can be achieved.

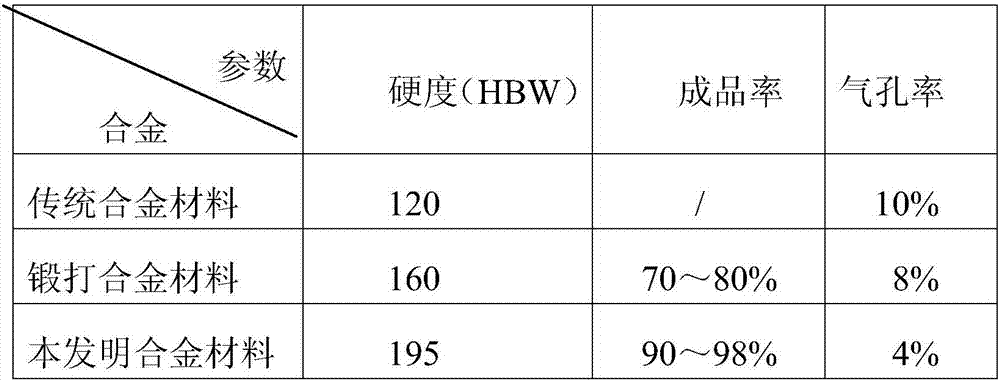

[0038] Material experiment data performance comparison table:

[0039]

[0040] It can be seen from the above table that the hardness and yield of the material are improved and the porosity of the material is reduced through the casting of the material in the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com