Method for preparing multilevel-structure alumina by pattern prefabrication through micro-nano ball arrangement

A technology of micro-nano spheres and alumina, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve problems such as low efficiency, high cost, and inability to achieve highly ordered structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Cut an aluminum sheet with a purity of 99.999% and a thickness of 0.3mm into small pieces of 1cm×2cm, anneal for 4 hours under the protection of high-purity nitrogen at 500°C, take it out and press it flat, and then ultrasonically clean it in acetone for 1 hour. The aluminum sheet treated above was subjected to anodic electrochemical polishing treatment in a mixed solution of ethanol and perchloric acid (volume ratio 4:1) at 4° C. with a voltage of 17 V, and then rinsed with distilled water.

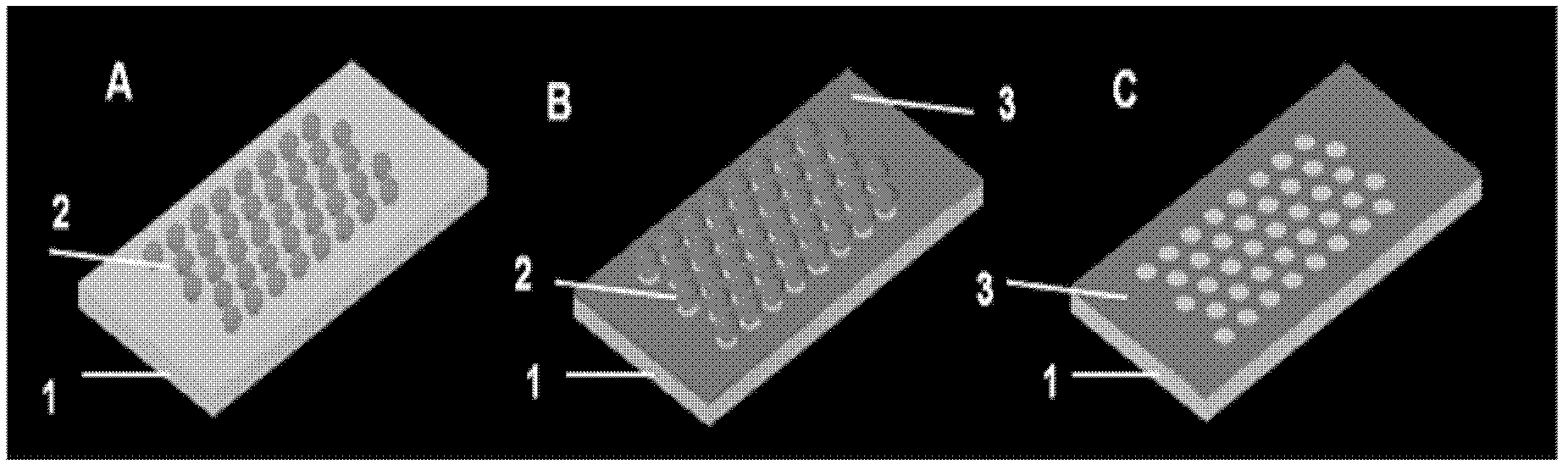

[0025] 2. Patterning process such as figure 1 shown. Select polystyrene microspheres (references: Zhang, J.H.; Chen, Z.; Wang, Z.L.; Zhang, W. Y.; Ming, N.B. Mater. Lett. 2003, 57, 4466-4470) with a particle size of 535 nm. The method of assembling makes it arrange into a monolayer film according to the hexagonal close-packing mode, and the specific method is that the mixed solution of polystyrene microspheres with water and ethanol volume ratio of 1:1 is made into a solution ...

Embodiment 2

[0030] 1. Cut a high-purity aluminum sheet with a purity of 99.999% and a thickness of 0.3mm into small pieces of 1cm×2cm, anneal for 4 hours under the protection of high-purity nitrogen at 500°C, take it out and press it flat, then ultrasonically clean it in acetone for 1 hour . The aluminum sheet treated above was subjected to anodic electrochemical polishing treatment in a mixed solution of ethanol and perchloric acid with a volume ratio of 4:1 at 4°C, and the controlled voltage was 17V, and then rinsed with distilled water.

[0031] 2. The whole patterning process as figure 1 shown. Select silica microsphere 2, adopt the method (X. Yan, J.Yao, G. Lu, X. Chen, K. Zhang, B. Yang, J.Am.Chem.Soc. 2004, 126, 10510. R. Micheletto, H. Fukuda, M. Ohtsu, Langmuir 1995, 11, 3333-3336.) make it orderly arranged on the polished aluminum sheet 1, the arrangement is a hexagonal structure, choose The particle size of the microspheres is 350nm; then the microspheres are etched smaller ...

Embodiment 3

[0034] 1. Cut a high-purity aluminum sheet with a purity of 99.999% and a thickness of 0.3mm into small pieces of 1cm×2cm, anneal for 4 hours under the protection of high-purity nitrogen at 500°C, take it out and press it flat, then ultrasonically clean it in acetone for 1 hour . The aluminum sheet treated above was subjected to anodic electrochemical polishing treatment in a mixed solution of ethanol and perchloric acid with a volume ratio of 4:1 at 4°C, and the controlled voltage was 17V, and then rinsed with distilled water.

[0035] 2. Patterning process such as figure 1 shown. Select 680nm polystyrene microspheres (references: Zhang, J.H.; Chen, Z.; Wang, Z.L.; Zhang, W. Y.; Ming, N.B. Mater. Lett. 2003, 57, 4466-4470), using the method of interface assembly, Make it arranged into a single-layer film according to the hexagonal close-packing method, use the polished aluminum sheet 1 as the substrate, and extract the single-layer film of polystyrene balls; use the method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com