Quickly assembling method for colloidal crystal with controllable layer number

A technology for colloidal crystals and an assembly method, which is applied in the fields of colloidal chemistry, colloidal chemistry, chemical instruments and methods, etc., can solve the problems of difficulty in obtaining colloidal crystals with a controllable number of layers, complicated and cumbersome preparation methods, and difficult to control, and achieves short preparation time. , The process is stable and controllable, and the effect of less influencing parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

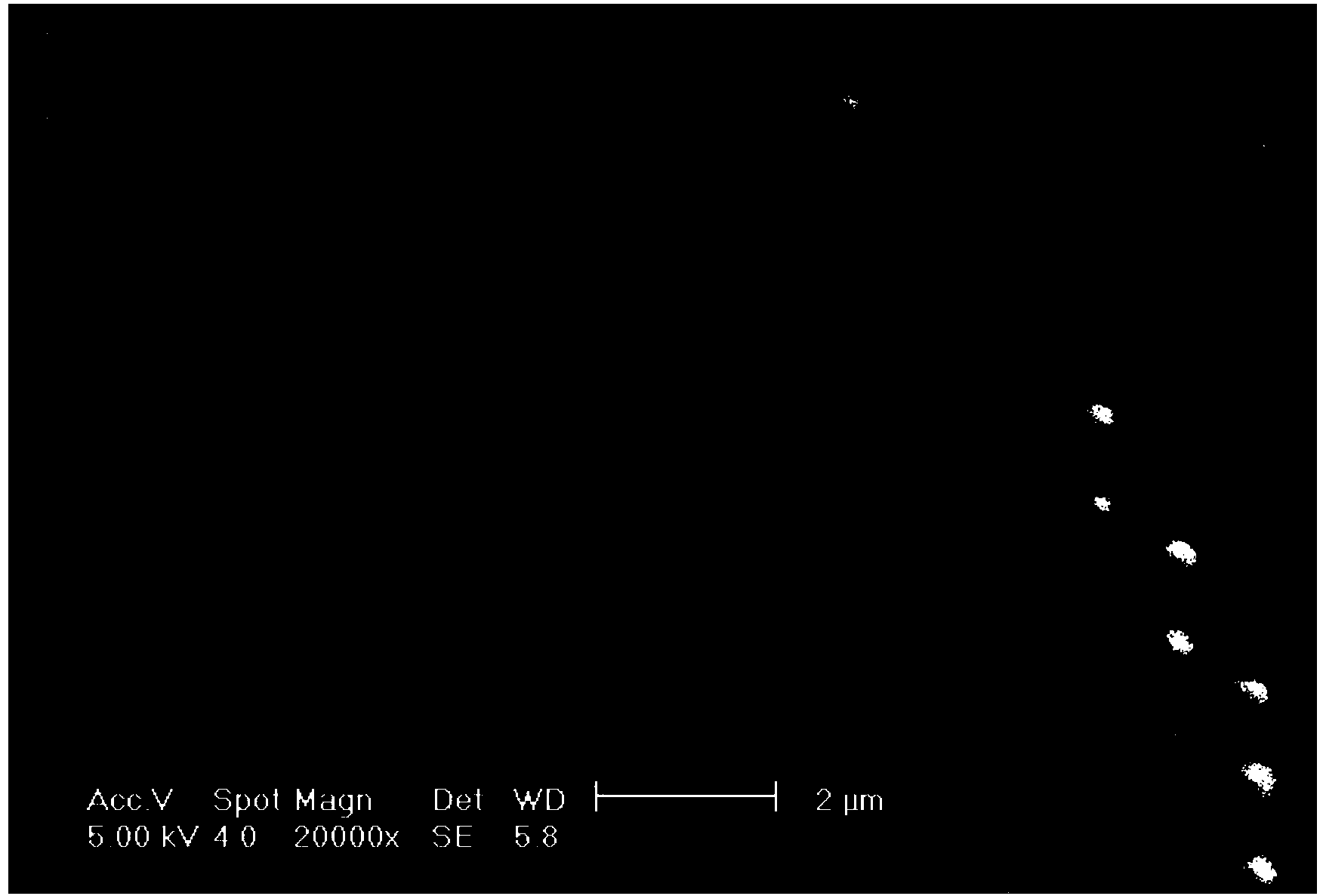

[0019] Inject ultrapure water accounting for 3 / 4 of the volume into the open container, and use a micro-injector to continuously drop polystyrene microsphere emulsion with a particle size of 1 μm on the water surface, and the drop rate of the emulsion is 5 μL / s. The volume fraction ratio of microspheres and alcohol in the styrene microsphere emulsion is 1:1. Stop dripping the emulsion when the polystyrene microspheres are completely covered with the water surface and form a layer of dense particle layer; carry out ultrasonic vibration on the open container, the ultrasonic frequency is 25KHZ, after 2 minutes the dense particle layer on the water surface presents a uniform Color; at this time, immerse the clean substrate under the liquid surface, and lift the substrate out of the liquid surface with a dipping and pulling device, and the linear speed of pulling is 5 μm / s. After drying at 80°C, highly ordered monolayer colloidal crystals were obtained, such as figure 1 and figu...

Embodiment 2

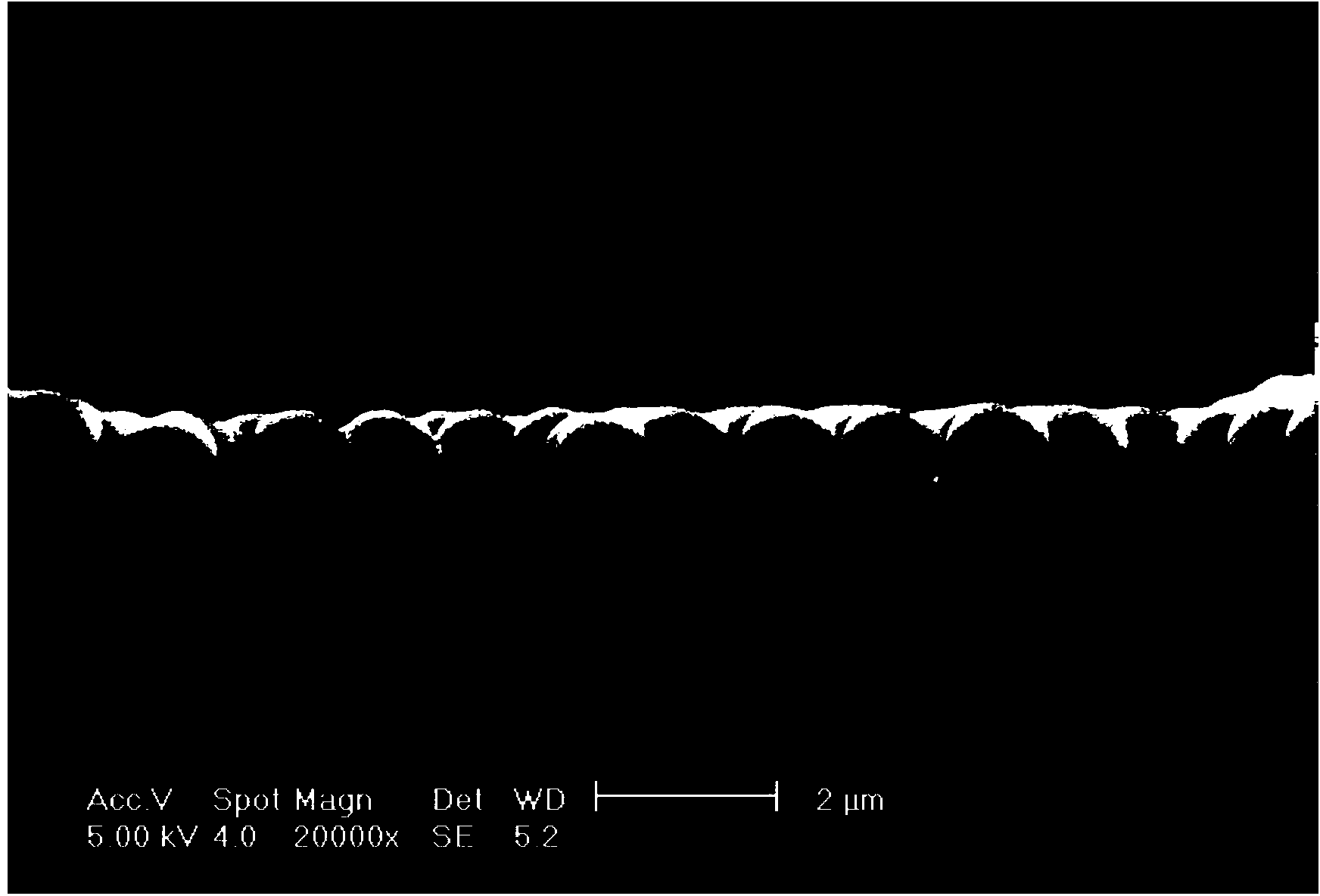

[0021] Inject ultrapure water accounting for 4 / 5 of the volume into the open container, and continuously drop the polystyrene microsphere emulsion with a particle size of 1 μm onto the water surface using a micro-injector. The drop rate of the emulsion is 100 μL / s. The volume fraction ratio of microspheres and alcohol in the styrene microsphere emulsion is 1:5. Stop dripping the emulsion when the polystyrene microspheres are completely covered with the water surface and form a dense granular layer; ultrasonically vibrate the open container, the ultrasonic frequency is 40KHZ, and the dense granular layer on the water surface appears uniform after 10 minutes. Color; at this time, the single-layer colloidal crystal prepared in Example 1 was immersed under the liquid surface, and lifted out of the liquid surface with a dipping and pulling device, and the linear speed of pulling was 500 μm / s. After drying at 100°C, highly ordered bilayer colloidal crystals were obtained, such as ...

Embodiment 3

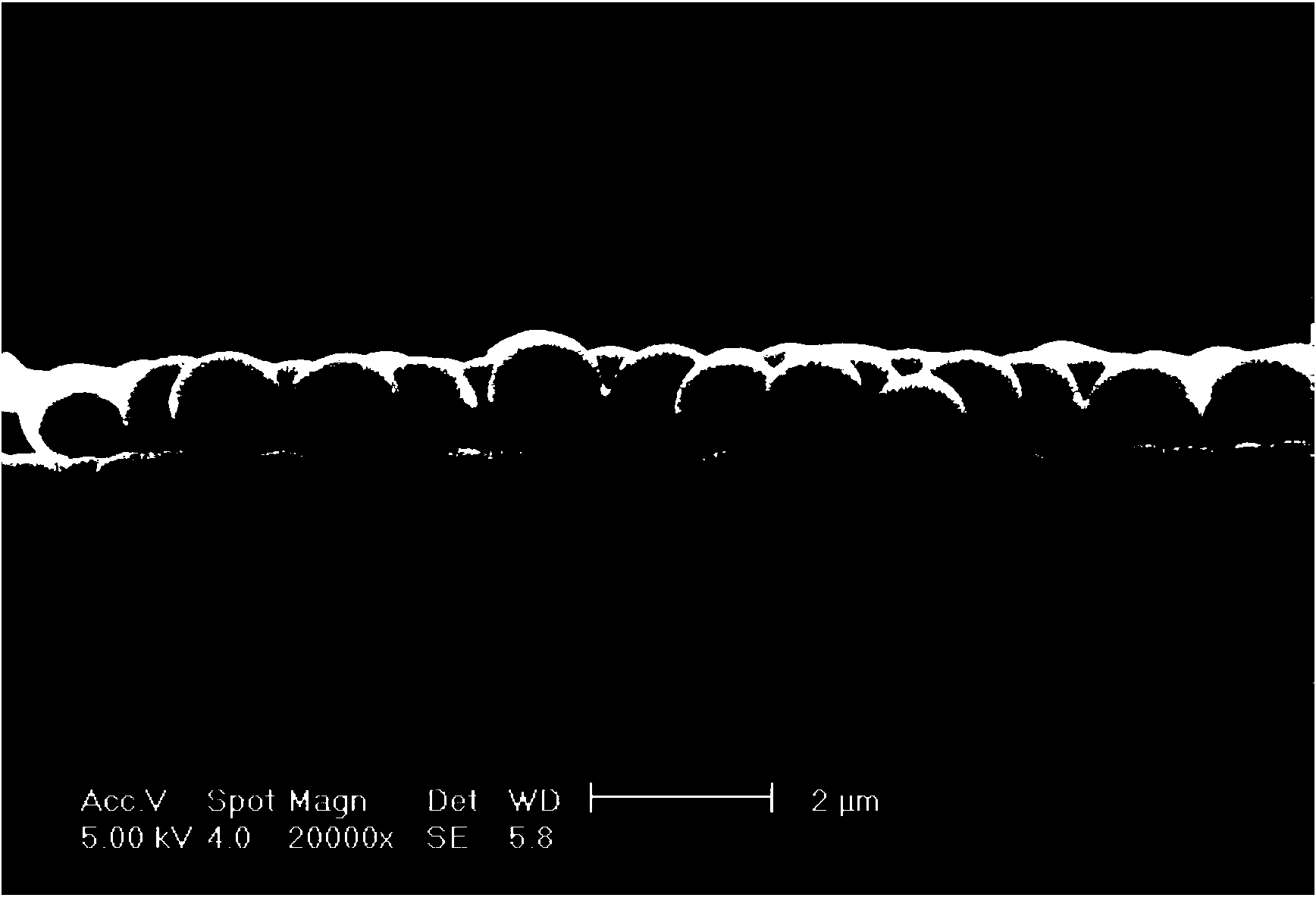

[0023] Inject ultrapure water accounting for 3 / 4 of the volume into the open container, and continuously drop the polystyrene microsphere emulsion with a particle size of 1 μm onto the water surface using a micro-injector, and the drop rate of the emulsion is 50 μL / s. The volume fraction ratio of microspheres and alcohol in the styrene microsphere emulsion is 1:2. Stop dripping the emulsion when the polystyrene microspheres are completely covered with the water surface and form a layer of dense particle layer; carry out ultrasonic vibration on the open container, the ultrasonic frequency is 25KHZ, after 2 minutes the dense particle layer on the water surface presents a uniform Color; at this time, the double-layer colloidal crystal prepared in Example 2 was immersed under the liquid surface, and lifted out of the liquid surface with a dipping and pulling device, and the linear speed of pulling was 200 μm / s. After drying at 90°C, highly ordered three-layer colloidal crystals we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com