Preparation method for nano SiO2 lattice on 316L stainless steel surface

A stainless steel and nanotechnology, applied in the field of preparation of nano-SiO2 lattices on the surface of 316L stainless steel, can solve the problems of wear resistance, corrosion resistance, lack of biological activity, etc. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

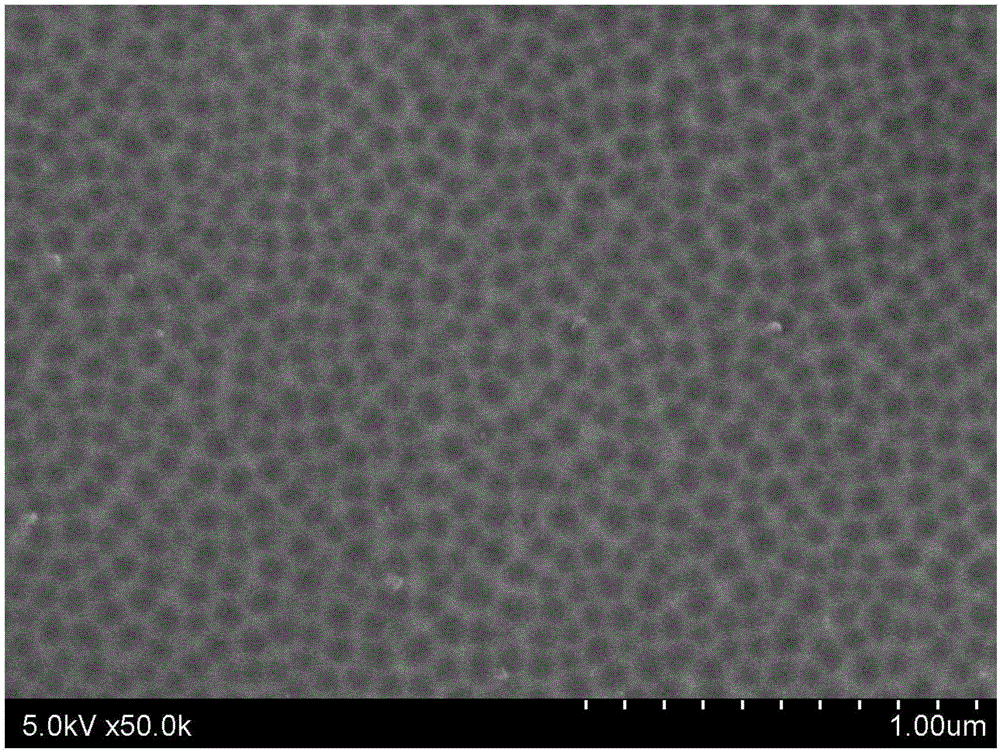

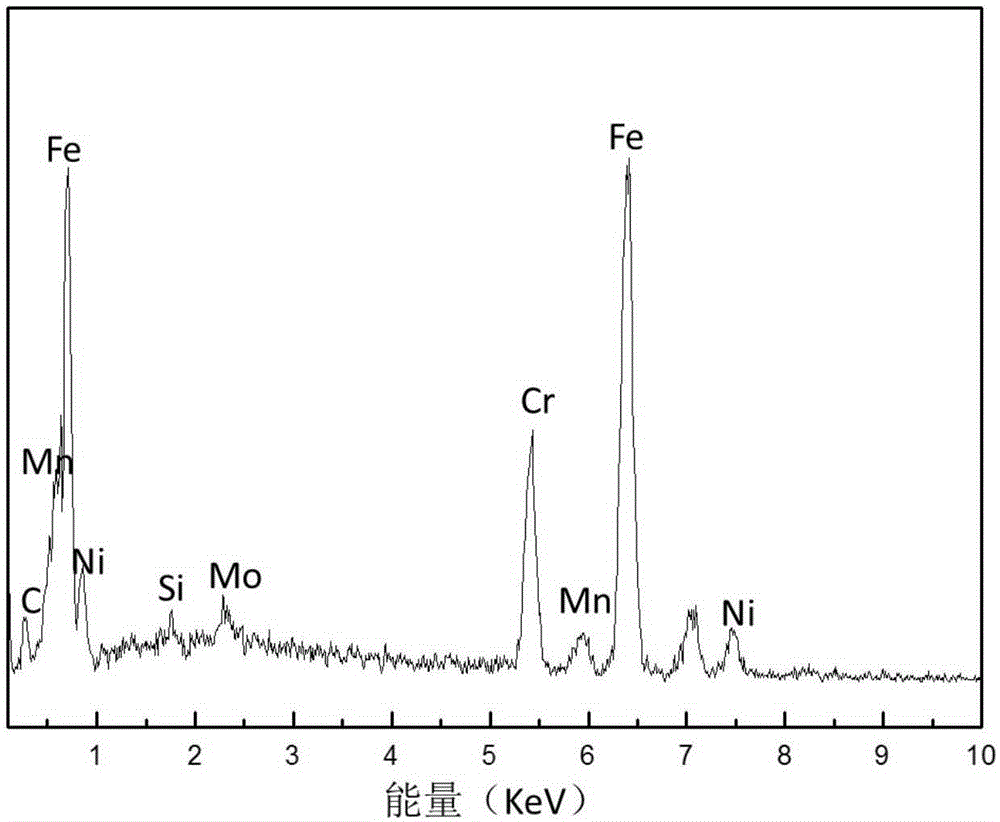

[0035] (1) Preparation of 316LSS surface nano-pit array: 316LSS is mixed in a mixture of perchloric acid and ethylene glycol (V:V=1:15), the system solution temperature is 10℃, 20V anodization is 15min, and the pit diameter is 50nm.

[0036] (2) SiO 2 Preparation of sol: mix 11.60mL of deionized water with 0.1ml of 2mol / L nitric acid, stir to make it uniform, and then add dropwise nitric acid acidified aqueous solution to 21.33mL of ethyl orthosilicate while stirring. Continue, the stirring time is 30min, the stirring temperature is 40℃, and finally SiO is formed 2 Sol; (The volume ratio of ethyl orthosilicate, deionized water and nitric acid is 1:0.54:0.005)

[0037] (3) SiO 2 The viscosity of the sol is 0.001 Pa·s, and it is dropped into a small glass bottle containing 316LSS with a nano-pit array on the surface at 20°C, the diameter of the sol is 50 nm, and it is allowed to stand for 24 hours.

[0038] (4) Take out the obtained sample, rinse it repeatedly with deionized water and...

Embodiment 2

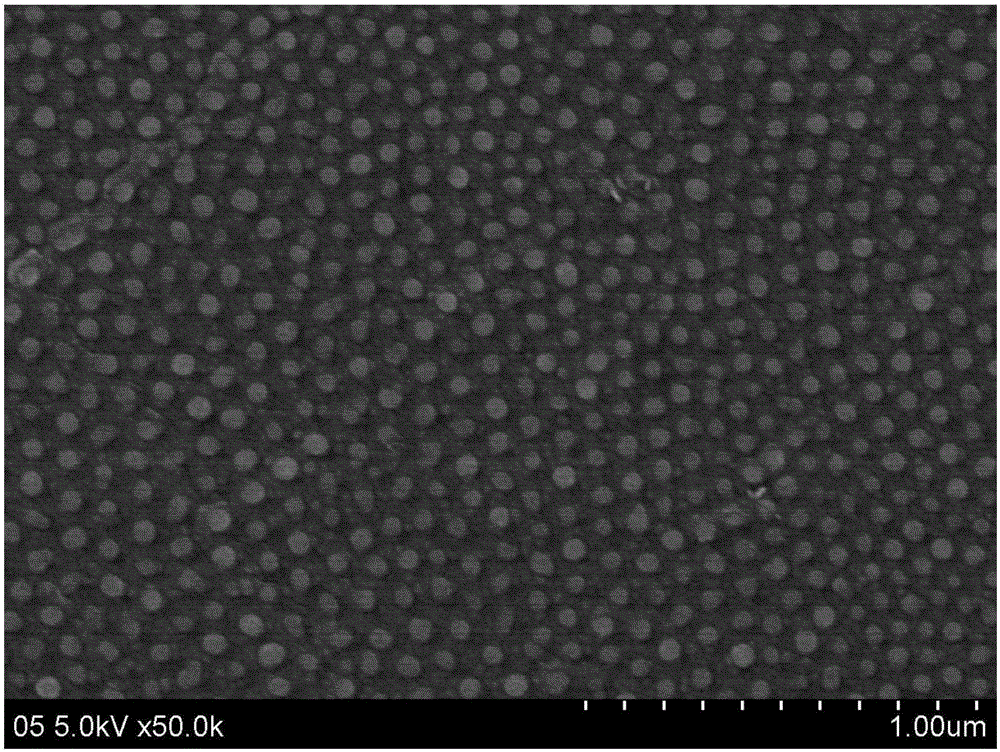

[0044] (1) Preparation of 316LSS surface nano-pit array: 316LSS was anodized in a mixture of perchloric acid and ethylene glycol (V:V=1:19) at 2°C and 40V for 11min, and the pit diameter was 70nm.

[0045] (2) SiO 2 Preparation of the sol: mix 13.7mL of deionized water with 0.15ml of 2mol / L nitric acid, stir to make it uniform, and then add dropwise nitric acid acidified aqueous solution to 17.4mL of methyl orthosilicate while stirring. Continue, stirring time is 40min, stirring temperature is 20℃, and finally SiO is formed 2 Sol (the volume ratio of ethyl orthosilicate, deionized water and nitric acid is 1:0.79:0.009).

[0046] (3) SiO 2 The viscosity of the sol is 0.002Pa·s, and it is dropped into a small glass bottle containing 316LSS with a nano-pit array on the surface at 30°C, the pit diameter is 70nm, and it is left to stand for 18h.

[0047] (4) Take out the obtained sample, wash it repeatedly with deionized water and ethanol for several times, and then dry it at 140°C for 1 ...

Embodiment 3

[0050] (1) Preparation of 316LSS surface nano-pit array: 316LSS was anodized in a mixture of perchloric acid and ethylene glycol (V:V=1:25) at 0°C and 70V for 30s, and the pit diameter was 150nm.

[0051] (2) SiO 2 Preparation of sol: mix 27.4mL of deionized water with 0.5ml of 2mol / L nitric acid, stir to make it uniform, and then add dropwise nitric acid acidified aqueous solution to 27.4mL of ethyl orthosilicate while stirring. Continue, the stirring time is 30min, the stirring temperature is 5℃, and finally SiO is formed 2 Sol (the volume ratio of ethyl orthosilicate, deionized water and nitric acid is 1:1:0.018).

[0052] (3) SiO 2 The viscosity of the sol is 0.002Pa·s, and it is dropped into a small glass bottle containing 316LSS with a nano-pit array on the surface at 30°C, the diameter of the sol is 150nm, and it is left for 4h.

[0053] (4) Take out the obtained sample, wash it repeatedly with deionized water and ethanol for several times, and then dry it at 65°C for 8 hours....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com