Preparation method of porous anodic aluminum oxide film

A technology of aluminum oxide film and porous anode, which is applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems affecting the order degree of porous anodized aluminum oxide film, long anodizing time, and poor order degree of oxide film. and other problems, to achieve the effect of shortening the production cycle, low cost and large scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0017] The preparation method of the porous anodic aluminum oxide membrane of the present embodiment has the following steps:

[0018] ① Pretreatment of pure aluminum surface:

[0019] First, soak pure aluminum in absolute ethanol for 5 minutes to remove oil stains from surface machining. Then, wash the pure aluminum with clean water to remove dust and dirt on the surface of the pure aluminum. Next, the pure aluminum washed with water was placed in an alkaline solution at 60° C. for 30 seconds, thereby removing the natural thin oxide layer on the surface of the pure aluminum. The alkaline solution was an aqueous solution containing 20 g of sodium hydroxide per liter. Next, take out the pure aluminum and wash it with water again, and place it in a dilute nitric acid solution with a volume percentage of 25% for 30 seconds. Finally, the pure aluminum was taken out and ultrasonically cleaned with deionized water for 5 min.

[0020] ② Put the pure aluminum pretreated in step ① a...

Embodiment 2~ Embodiment 4)

[0029] The preparation method of each embodiment is basically the same as that of Example 1, and the differences are shown in Table 1.

[0030] Table 1

[0031]

[0032]

[0033] .

Embodiment 5)

[0035] The preparation method of this embodiment is basically the same as that of Example 1, except that step ②: the pure aluminum after step ① pretreatment is used as the anode and put into the electrochemical polishing solution together with graphite as the cathode, at a voltage of 20V Electrochemical polishing was carried out for 30 s to form a nanoscale porous film on the surface of pure aluminum.

[0036] The above electrochemical polishing solution is composed of absolute ethanol and perchloric acid in a weight ratio of 4:1.

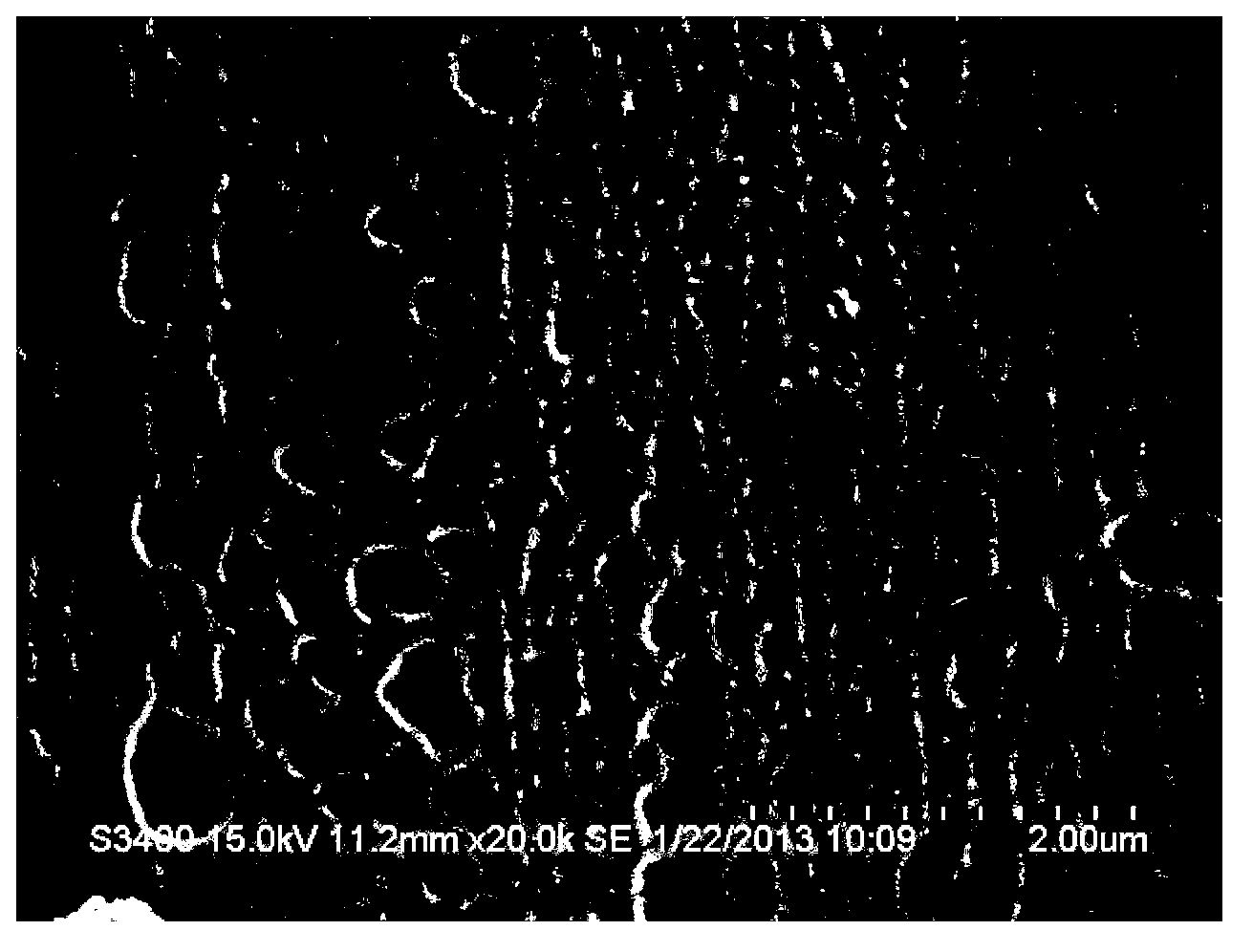

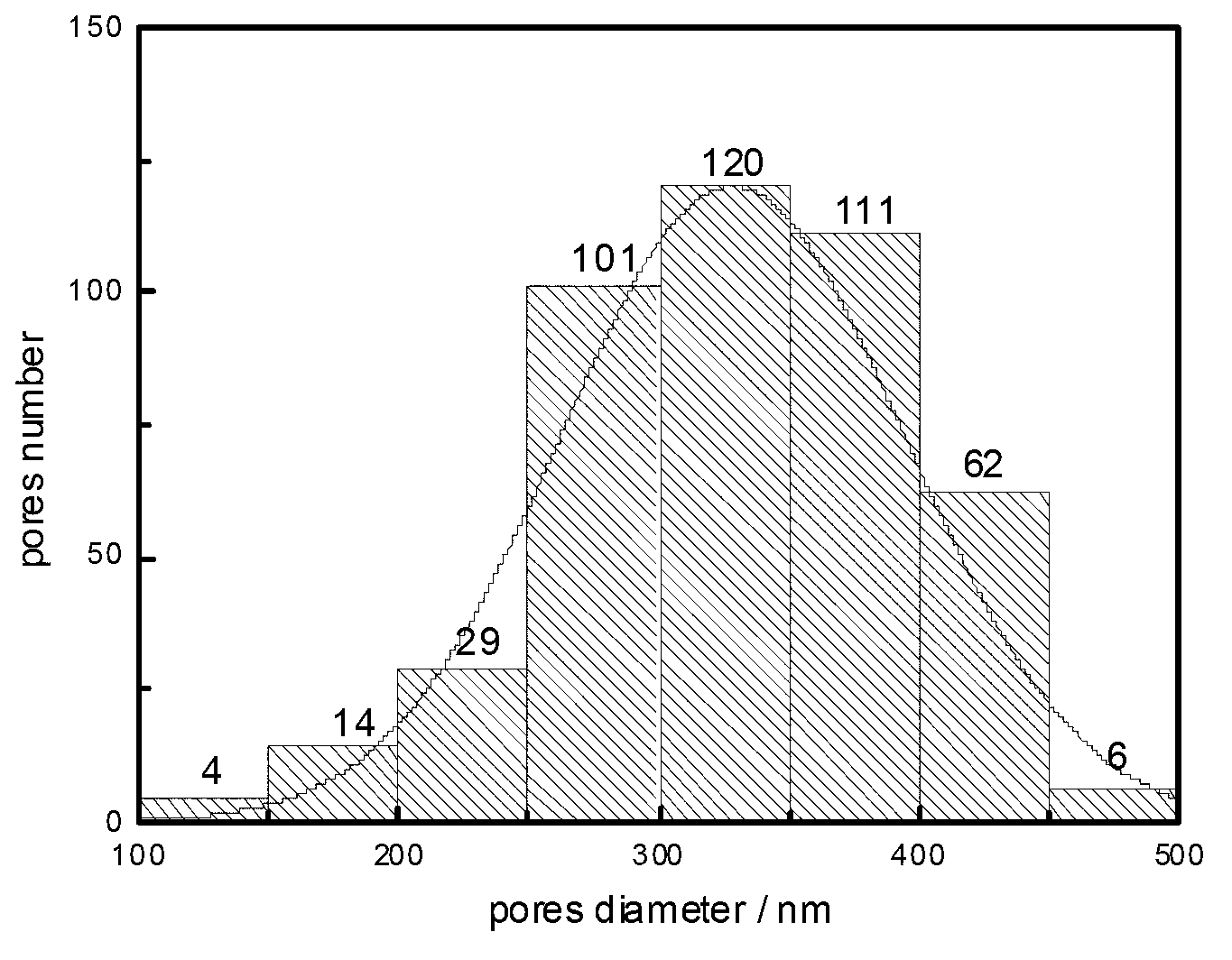

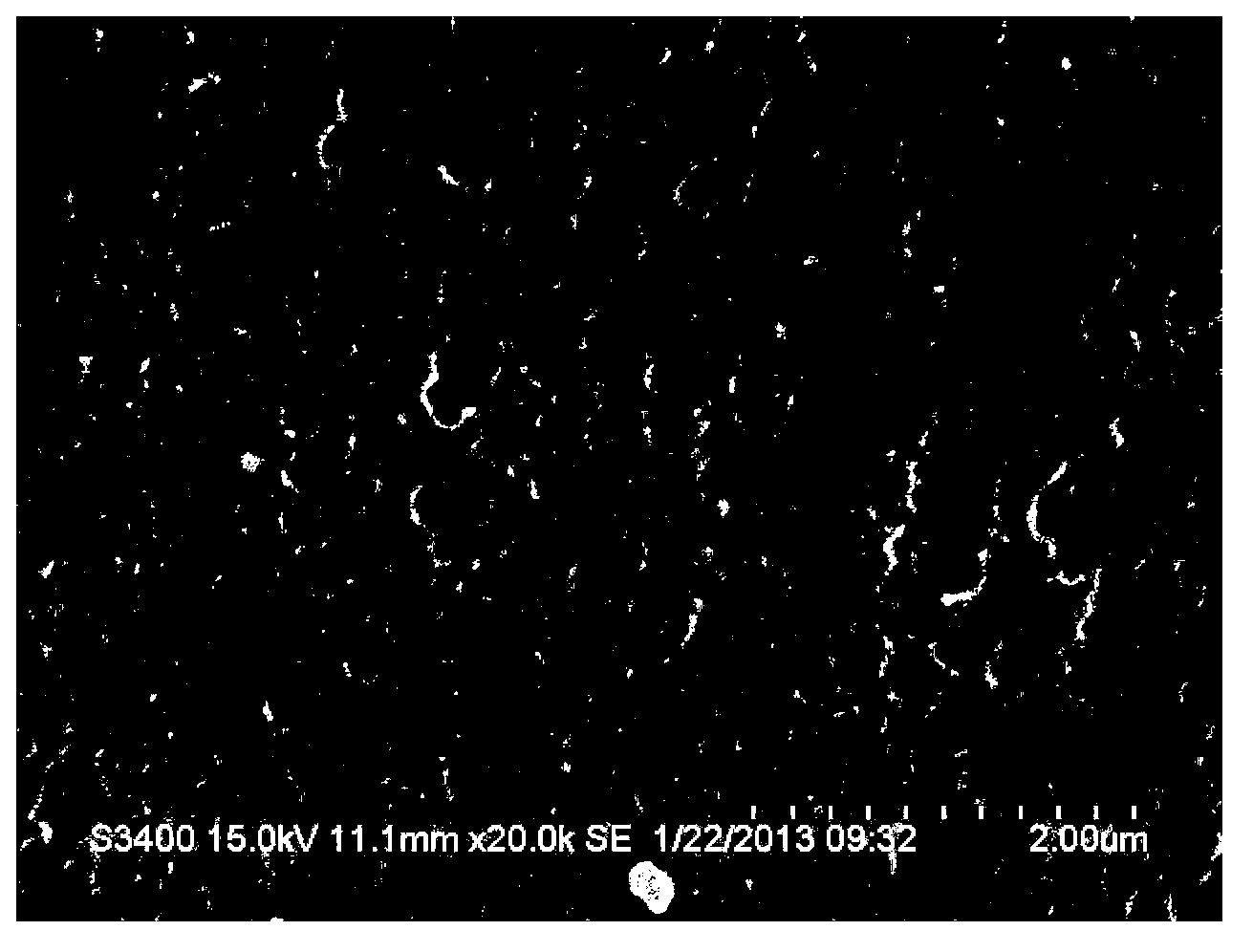

[0037] The scanning electron microscope picture of the surface of the porous anodized aluminum oxide film prepared in this embodiment is shown in image 3 , pore size distribution diagram see Figure 4 ,Depend on image 3 and Figure 4 It can be seen that the pore size distribution of the porous anodized aluminum oxide membrane prepared in this example is slightly worse, the porosity is only about 5%, and the average pore size is 80nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com