Polycarboxylic acid water reducing agent with excellent rust resisting function and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of concrete water reducing agent for construction engineering materials, can solve the problems of limited application, concrete cannot be used alone, and has no water reducing function, and achieves simple process, mild reaction conditions, and easy scale The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

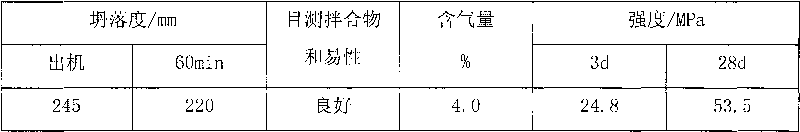

Examples

Embodiment 1

[0017] (1) The first step esterification reaction: 90.0 g of polyethylene glycol monomethyl ether with a molecular weight of 1000, 20.0 g of acrylic acid, 0.12 g of sodium benzoate, 0.36 g of benzotriazole, 1.0 g of 98% concentrated sulfuric acid, press Put the above sequence into a 250ml three-necked flask reaction vessel, heat while stirring, cover the bottle mouth and seal, heat up to 110-120°C, keep warm for 4 hours for esterification reaction, and generate polyethylene glycol triazole-based acrylate a; when the temperature is lowered to 50°C, add 50g of water to dilute the solution to about 70% for later use;

[0018] (2) The second polymerization reaction: Add 60g of bottom water into a 250ml four-necked flask, and when the temperature rises to 90±5°C while stirring, add 110g of the reactant solution of the first step dropwise while adding the mass ratio 37g of 3% ammonium persulfate solution, control the rate of addition, drop it at the same time in about 120 minutes, k...

Embodiment 2

[0020] (1) The first step of esterification reaction: 108.0 g of polyethylene glycol monomethyl ether with a molecular weight of 1200, 22.0 g of acrylic acid, 0.13 g of sodium benzoate, 0.39 g of benzotriazole, 1.1 g of 98% concentrated sulfuric acid, press Put the above sequence into a 250ml three-necked flask reaction vessel, heat while stirring, cover the bottle mouth and seal, heat up to 110-120°C, keep warm for 4 hours for esterification reaction, and generate polyethylene glycol triazole-based acrylate a; when the temperature is lowered to 50°C, add 55g of water to dilute the solution to about 70% for later use;

[0021] (2) The second polymerization reaction: Add 60g of bottom water into a 250ml four-necked flask, and when the temperature rises to 90±5°C while stirring, add 110g of the reactant solution of the first step dropwise while adding the mass ratio 39g of 3% ammonium persulfate solution, control the rate of addition, drop it at the same time in about 120 minute...

Embodiment 3

[0023] (1) The first step of esterification reaction: 120.0 g of polyethylene glycol monomethyl ether with a molecular weight of 1500, 23.0 g of acrylic acid, 0.15 g of sodium benzoate, 0.45 g of benzotriazole, 1.2 g of 98% concentrated sulfuric acid, press Put the above sequence into a 250ml three-necked flask reaction vessel, heat while stirring, cover the bottle mouth and seal, heat up to 110-120°C, keep warm for 4 hours for esterification reaction, and generate polyethylene glycol triazole-based acrylate a; when the temperature is lowered to 50°C, add 60g of water to dilute the solution to about 70% for later use;

[0024] (2) The second polymerization reaction: Add 60g of bottom water into a 250ml four-necked flask, and when the temperature rises to 90±5°C while stirring, add 110g of the reactant solution of the first step dropwise while adding the mass ratio 39g of 3% ammonium persulfate solution, control the rate of addition, drop it at the same time in about 120 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com