Manufacturing method of double-high-energy-beam metal additive material

A manufacturing method and metal additive technology, which is applied in the field of metal additive manufacturing, can solve problems such as large residual stress, pores, and surface roughness, and achieve the goal of improving hardness and thermal fatigue resistance, improving dimensional accuracy, and improving surface morphology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

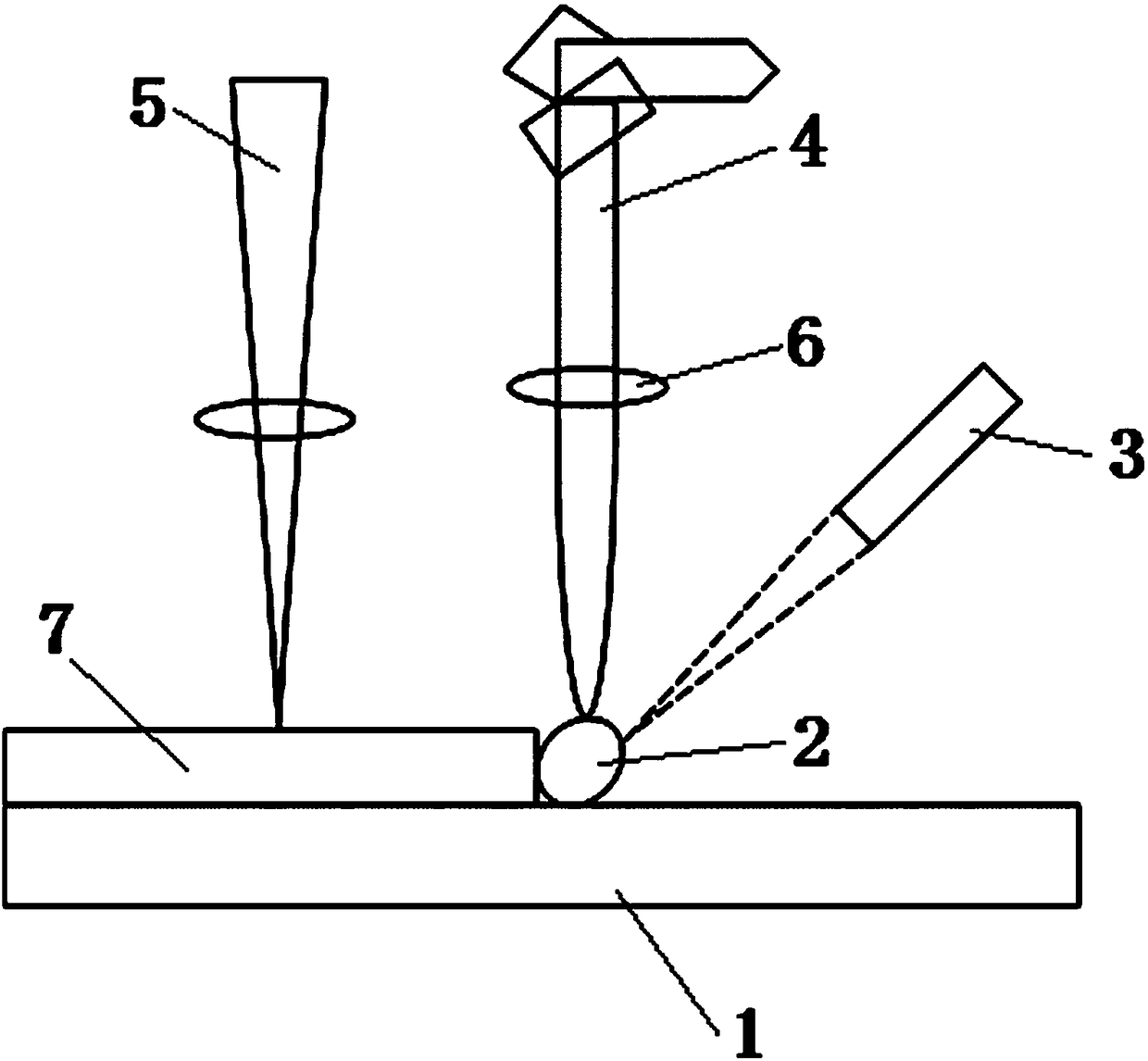

Image

Examples

Embodiment 1

[0029] a) Determine the three-dimensional solid model and modeling of the formed component: the digital model type of the formed part of the present invention is the digital model type of double high-energy beam forming, which is defined as: the first high-energy beam is produced by a continuous fiber laser, and the second high-energy beam It is generated by a nanosecond pulsed laser, and the first high-energy beam and the second high-energy beam have the same trajectory, with an interval of 20ms; then use CAD 3D software to establish the 3D shape of the formed part in the control system of the SLM additive manufacturing equipment. Digital model;

[0030] b) Additive manufacturing of formed parts: slice and layer the digital model in step a), obtain the two-dimensional profile information of each layer section and generate the processing path; import the above information into the control system of the SLM additive manufacturing equipment, Put the titanium alloy powder with a ...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that the additive manufacturing equipment used is LENS additive manufacturing equipment, the first high-energy beam additive manufacturing process adopts the LENS forming process to obtain the formed sheet, and the other conditions are the same as the embodiment.

[0041] After testing, the formed parts prepared in this embodiment avoid internal defects such as pores, incomplete fusion, cracks, etc., and the dimensional accuracy of the formed parts is high, and the surface roughness of the formed parts is low.

Embodiment 3

[0043] The difference between this embodiment and Embodiment 1 is that the first high-energy beam is produced by an electron gun, and the additive manufacturing equipment used is EBM additive manufacturing equipment. The first high-energy beam additive manufacturing process adopts the EBM forming process to obtain a formed sheet , the electron beam current of the electron gun in the additive manufacturing process is 15mA, the scanning speed is 500mm / s, the electron beam spot diameter is 80μm, and other conditions are the same as in the embodiment.

[0044] After testing, the formed parts prepared in this embodiment avoid internal defects such as pores, incomplete fusion, cracks, etc., and the dimensional accuracy of the formed parts is high, and the surface roughness of the formed parts is low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com