Electrical heating anti-icing assembly with superhydrophobic property and preparation method of electrical heating anti-icing assembly

An electric heating element, electric heating technology, applied in deicing devices, chemical instruments and methods, aircraft parts, etc., can solve the problems of high energy consumption, inability to meet deicing requirements, low working efficiency of electric heating deicing devices, etc. Reduced adhesion strength, shortened heating time, high practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

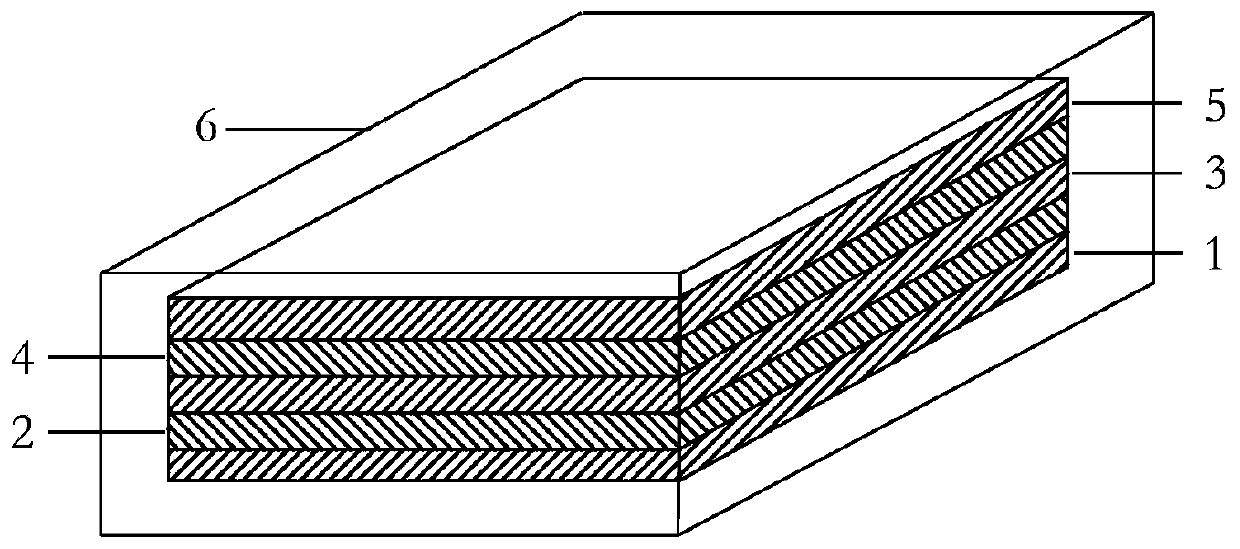

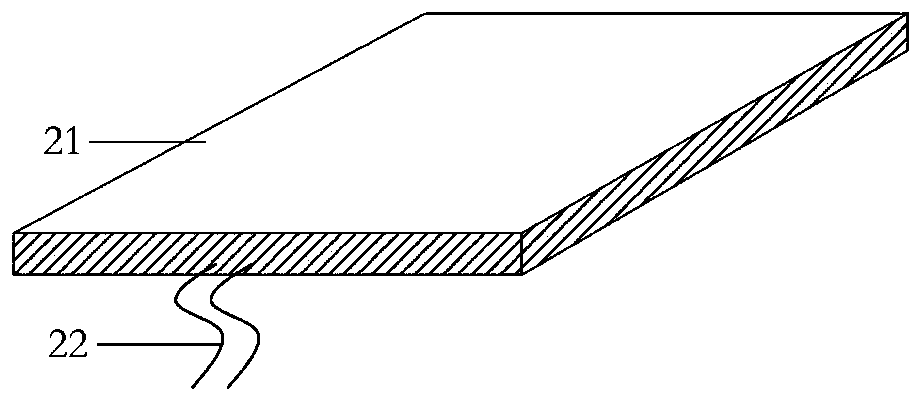

[0049] Step1: sticky electric heating layer

[0050] Select a piece of AMANDA-800 (Amanda) insulation board with a size of 10cm length × 10cm width × 0.3mm thickness, and cover a layer of graphite with a size of 9cm length × 9cm width × 0.05mm thickness at the center of the insulation insulation board Graphene heating sheet (the graphene heating sheet is connected with a power supply cable), the graphene heating sheet (electrical heating element) and the insulating and heat insulating board are combined by bonding with RTV adhesive, and cured at room temperature for 24h.

[0051]Step2: Stick the insulation and heat conduction layer

[0052] Cover the upper surface of the graphene heating sheet with a jyxjb-24 (OUPLI) insulating thermal pad with a size of 10cm long × 10cm wide × 0.3mm thick, and use RTV adhesive to insulate jyxjb-24 (OUPLI) by bonding The thermal pad is combined with the graphene heating sheet.

[0053] Step3: Paste the thermally conductive metal layer

[00...

Embodiment 2

[0069] Step1: sticky electric heating layer

[0070] Select a piece of VESPEL-SP1 board (that is, PI board, the main component is polyimide) with a size of 10cm long × 10cm wide × 0.35mm thick as an insulating and heat insulating board, and cover a layer of 8cm in size at the center of the insulating and heat insulating board A graphene heating sheet (the graphene heating sheet is connected with a power supply cable) of length × 8cm width × 0.05mm thick, and the graphene heating sheet (electric heating element) and the insulating and heat-insulating plate are bonded with an RTV adhesive Combine together and cure at room temperature for 24 hours.

[0071] Step2: Stick the insulation and heat conduction layer

[0072] Cover the upper surface of the graphene heating sheet with an XK-F60 insulating thermal pad with a size of 10cm long × 10cm wide × 0.3mm thick, and heat the XK-F60 insulating thermal pad and graphene with RTV adhesive by bonding pieces together.

[0073] Step3: ...

Embodiment 3

[0083] Step1: sticky electric heating layer

[0084] Select a piece of AMANDA-800 (Amanda) insulation board with a size of 10cm length × 10cm width × 0.4mm thickness, and cover a layer of resistance with a size of 9cm length × 9cm width × 0.1mm thickness at the center of the insulation insulation board Wire heating sheet (the resistance wire heating sheet is connected with a power supply cable), the graphene heating sheet (electric heating element) and the insulation and heat insulation board are combined by bonding with RTV adhesive, and cured at room temperature for 24 hours.

[0085] Step2: Stick the insulation and heat conduction layer

[0086] Cover the upper surface of the graphene heating sheet with a jyxjb-24 (OUPLI) insulating thermal pad with a size of 10cm long × 10cm wide × 0.3mm thick, and use RTV adhesive to insulate jyxjb-24 (OUPLI) by bonding The thermal pad is combined with the graphene heating sheet.

[0087] Step3: Paste the thermally conductive metal laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com