Preparation of polyvinylidene fluoride dewatering microporous film

A polyvinylidene fluoride and microporous membrane technology, which is applied in the field of preparation of strong hydrophobic polyvinylidene fluoride microporous membranes, can solve the problems of non-penetrating membrane pores, accelerated film formation speed, high retention rate, etc. Effects of film formation speed, improved hydrophobicity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

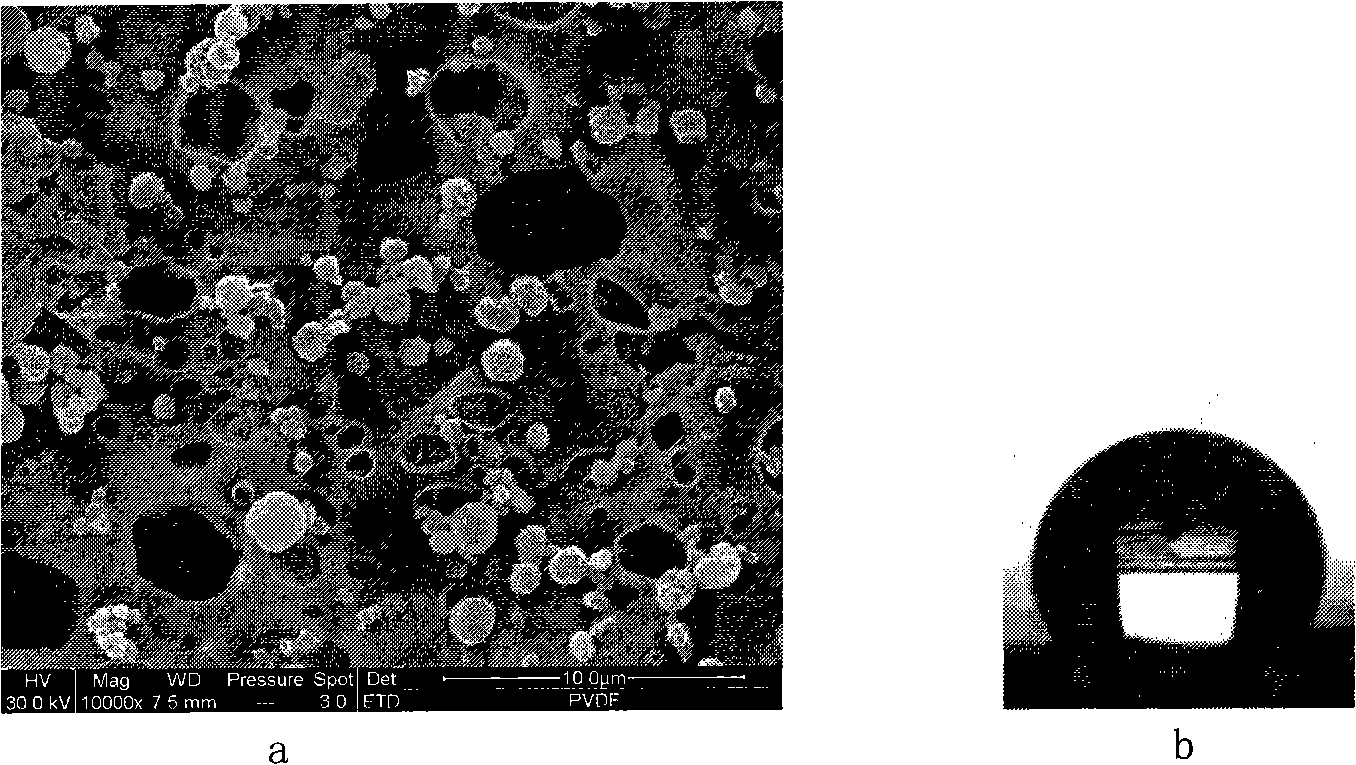

[0026] Polyvinylidene Fluoride Hydrophobic Microporous Membrane Prepared by Gel in Alkali Vapor and Then in Acid

[0027] 1) The total amount of casting solution is 100g. First, mix PVDF (10wt%), DMAC (70wt%), LiCl (4wt%), tetraethoxysilane TEOS (16wt%) and stir for 6 hours with a magnetic stirrer , to obtain a clarified casting solution, and then place it in a 50°C oven for 48 hours to fully mature and defoam;

[0028] 2) Scrape the casting solution obtained in step 1) on a glass plate into a 0.15 mm thick liquid film with a scraper, then immediately place the glass plate in an atmosphere of NaOH alkali vapor with a pH of 12 and a relative humidity of 85%. , keep the liquid film in the alkali vapor atmosphere for 4 minutes to obtain the nascent film;

[0029] 3) Then immerse the nascent membrane in a hydrochloric acid gel bath (20°C, pH = 1). After the membrane is completely peeled off from the glass plate, continue to soak in the gel bath for 30 minutes, and then transfer t...

Embodiment 2

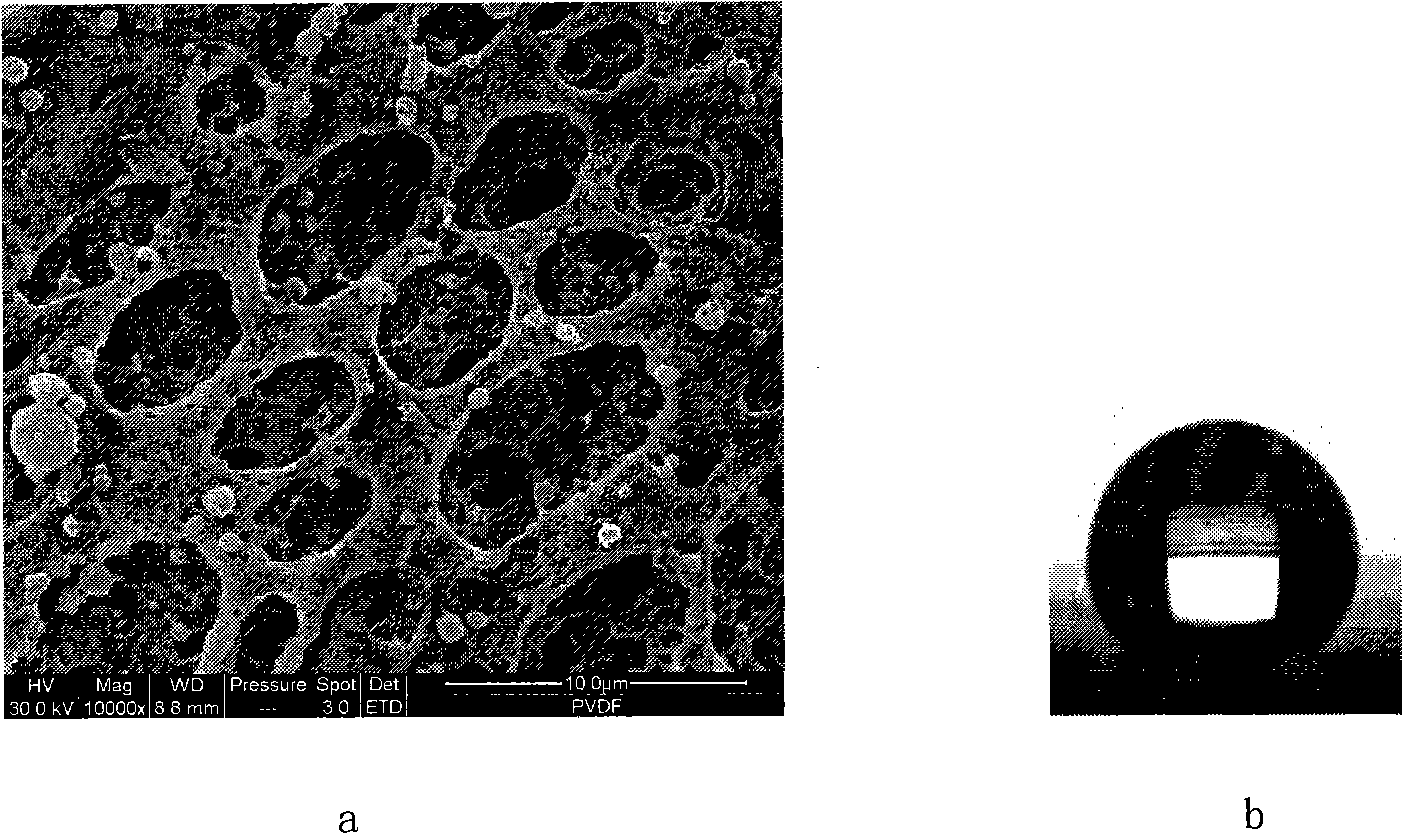

[0032] Polyvinylidene Fluoride Hydrophobic Microporous Membrane Prepared by Gel in Alkali Vapor and Then in Acid

[0033] 1) The total amount of casting solution is 100g. First, mix PVDF (10wt%), DMAC (64wt%), LiCl (4wt%) and TEOS (22wt%) and stir for 6 hours with a magnetic stirrer to obtain a clarified casting solution. Membrane solution, and then put it in an oven at 50°C for 48 hours to fully mature and defoam;

[0034] 2) Scrape the casting solution obtained in step 1) on a glass plate into a 0.15mm thick liquid film with a scraper, then immediately place the glass plate in an atmosphere of NaOH alkali vapor with a pH of 13 and a relative humidity of 85%. , keep the liquid film in the alkali vapor atmosphere for 4 minutes to obtain the nascent film;

[0035] 3) Then immerse the nascent membrane in a hydrochloric acid gel bath (20°C, pH=3). After the membrane is completely peeled off from the glass plate, continue to soak in the gel bath for 30 minutes, and then transfer ...

Embodiment 3

[0038] Polyvinylidene Fluoride Hydrophobic Microporous Membrane Prepared by Gel in Water Vapor and Then in Acid

[0039] 1) The total amount of casting solution is 100g. First, mix PVDF (10wt%), DMAC (73wt%), LiCl (5wt%) and TEOS (12wt%), and stir for 7 hours with a magnetic stirrer to obtain a clarified casting solution. Membrane solution, and then put it in an oven at 50°C for 48 hours to fully mature and defoam;

[0040] 2) After scraping the casting solution obtained in step 1) into a liquid film with a thickness of 0.15 mm on a glass plate, immediately place the glass plate in a water vapor atmosphere (relative humidity 80%) to allow the liquid film to Keep it in the water vapor atmosphere for 3 minutes to get the nascent eco-film;

[0041] 3) Then immerse the nascent membrane in a hydrochloric acid gel bath (18°C, pH=0.5). After the membrane is completely peeled off from the glass plate, continue to soak in the gel bath for 30 minutes, and then transfer to deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com