Method for preparing medical titanium alloy with bionic multilayered structure interface

A multi-layer structure, titanium alloy technology, applied in chemical instruments and methods, coatings, medical science, etc., can solve the problem of not providing a suitable extracellular microenvironment for cells, difficult to control the thickness of hydroxyapatite, difficult to control hydroxyphosphate limestone morphology and other issues, to achieve good biocompatibility and osseointegration, affinity, strong activity, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]Example 1. Construction of a biomimetic multilayer structure on the surface of a titanium alloy that promotes osteoblast differentiation

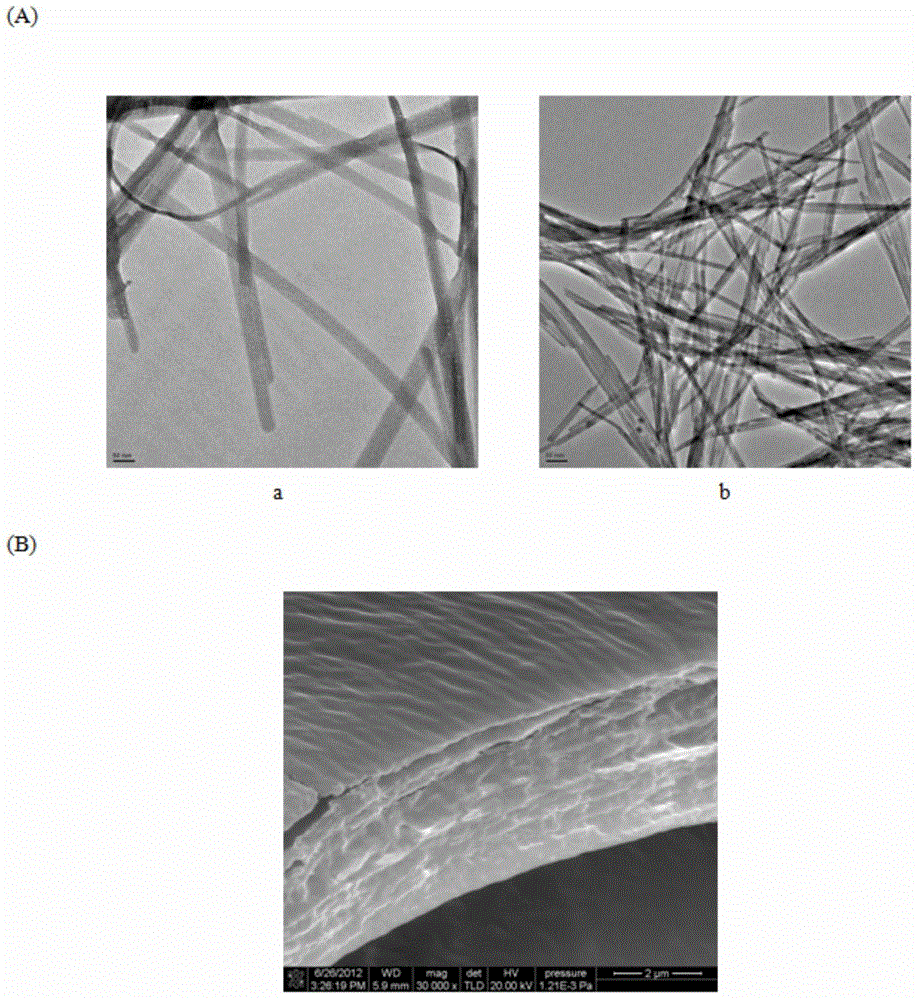

[0025] 1) Preparation of xonotlite nanowires: Calcium nitrate and sodium silicate were prepared into 0.5mol / L solutions respectively; secondly, calcium nitrate solution was added dropwise to sodium silicate solution, and magnetically stirred for 2 hours to form a white suspension Then the white suspension was transferred to a high-pressure reactor lined with tetrafluoroethylene, heated in an oil bath, and reacted at 200°C for 24 hours; the product was washed three times with absolute ethanol and distilled water, filtered, Freeze-dried overnight to obtain xonotlite nanowires.

[0026] 2) Preparation of hydroxyapatite nanowires: Trisodium phosphate was formulated into a solution with a concentration of 0.2 mol / L; 1 g of xonotlite precursor was added to 85 mL of trisodium phosphate solution, and magnetically stirred for 2 hours to form a...

experiment example 1

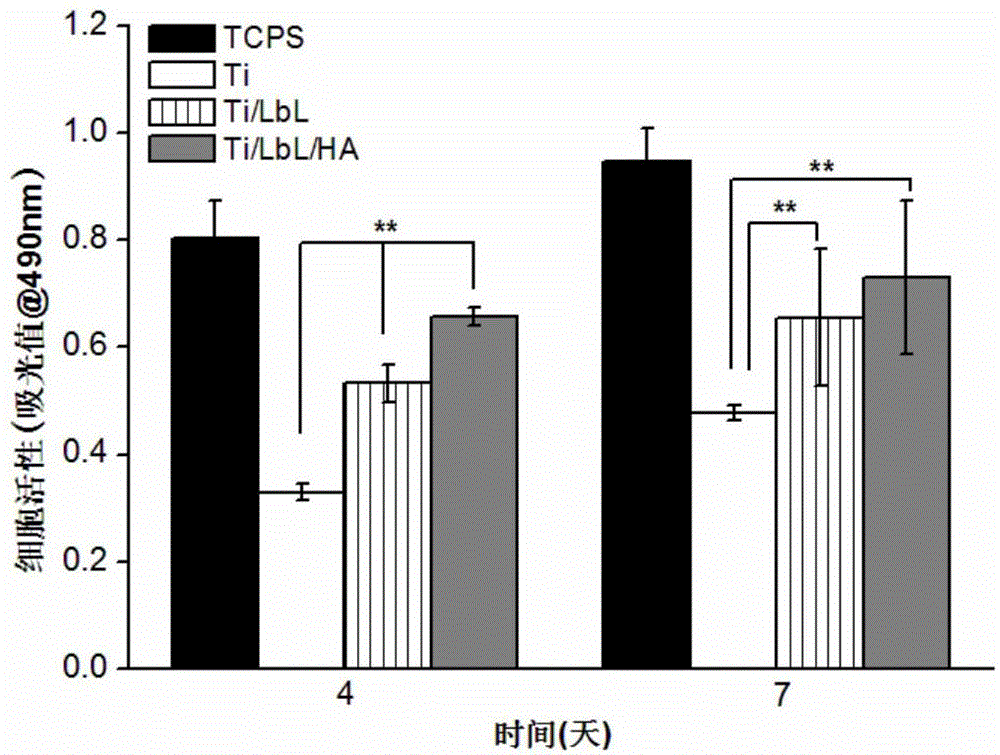

[0036] Experimental example 1. Cytocompatibility of titanium alloy after layered multilayer structure modification

[0037] This study investigated the cellular activity of osteoblasts on the surface of titanium alloys with multilayer structures.

[0038] The cytocompatibility of different modified titanium surfaces was characterized by MTT. When the primary osteoblasts were cultured to the third passage, 1×10 4 The density of the cells / wells is terminated on the surface of different modified titanium alloy sheets and on TCPS, cultured at 37°C and 5% CO2. After 4 days and 7 days, the culture medium was aspirated and discarded, and 1 mL of fresh serum-free medium and 100 μL of MTT solution (5 mg / mL) were added, and the culture was continued for 4 h. Aspirate the culture solution, add 500 μL dimethyl sulfoxide (DMSO), and when the crystals are completely dissolved, measure the absorbance value of each well at 490 nm.

[0039] MTT, tetrazolium salt, is a yellow dye that can en...

experiment example 2

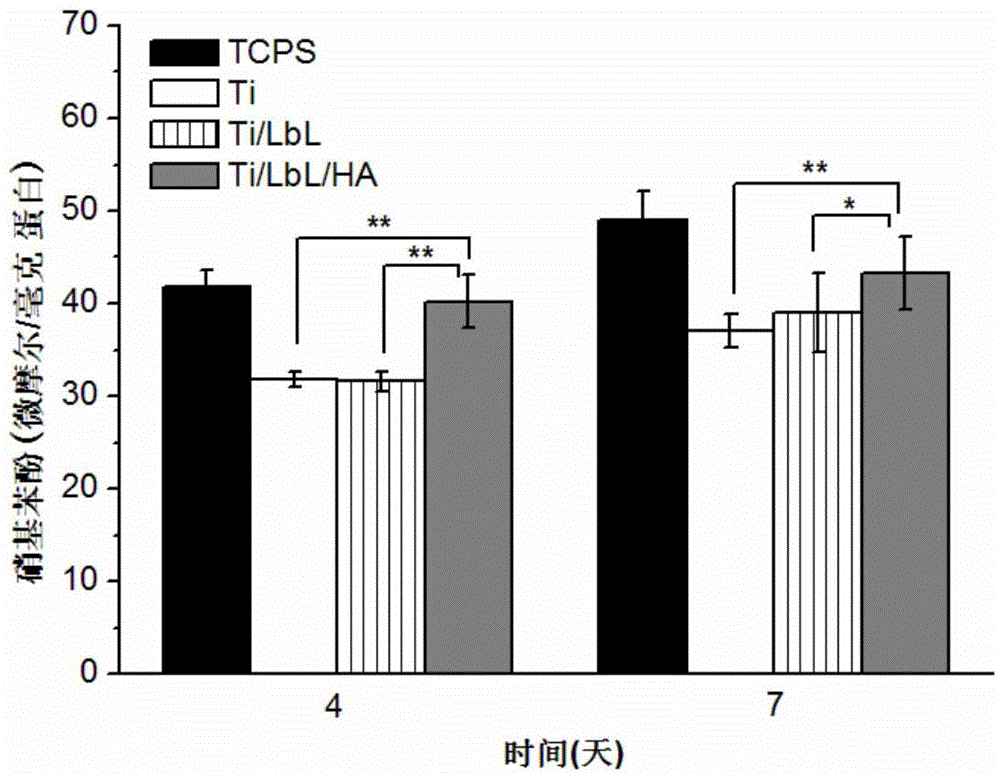

[0040] Experimental example 2. Alkaline phosphatase activity of osteoblasts on titanium alloy surface after layered multilayer structure modification

[0041] The third generation osteoblasts were divided into 2×10 4 The density of cell / well was seeded on the surface of each titanium sheet and TCPS. After culturing for 4 days and 7 days respectively, the cells were lysed with 1% TritonX-100 to obtain a cell lysate. With p-nitrophenol as the catalytic substrate of alkaline phosphatase, under the action of alkaline phosphatase, the reaction produces a yellow water-soluble product, the absorbance value is measured at a wavelength of 405nm, and the base of the corresponding experimental group is obtained according to the standard curve. Sexual phosphatase activity. From image 3 It can be found that after 4 days of culture, the Ti / LbL / HA group showed higher ALP activity than the Ti and Ti / LbL groups, and there was a very significant difference, while there was no difference bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com