Waterborne waterproof expansion-type fire-resistive coating for steel structures and preparation method of coating

A technology of fire-resistant coatings and section steel, applied in fire-resistant coatings, anti-corrosion coatings, coatings, etc., can solve the problems of low price of water-based fire-resistant coatings, endangering the health of construction workers, and reducing the fire-proof effect, so as to avoid the decline of fire-proof performance and moderate Good long-term fire and heat insulation effect, good fire and heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The preparation method of the above-mentioned water-based water-resistant expansion steel structure fireproof coating comprises the following steps:

[0063] 1) Add water, film-forming aids, wetting and dispersing agents, anti-fungal agents, anti-flash rust agents and pH regulators into the dispersion tank, and stir at a speed of 300-800r / min for 5-10 minutes;

[0064] 2) Add melamine-coated ammonium polyphosphate, dipentaerythritol, melamine and expanded perlite, and stir at a speed of 2000-3000r / min for 20-40min;

[0065] 3) Add water-based silicon-acrylic emulsion, defoamer and thickener, stir at a speed of 500-1000r / min for 20-40min, and discharge to obtain a water-based water-resistant expansion-type fireproof coating for steel structures.

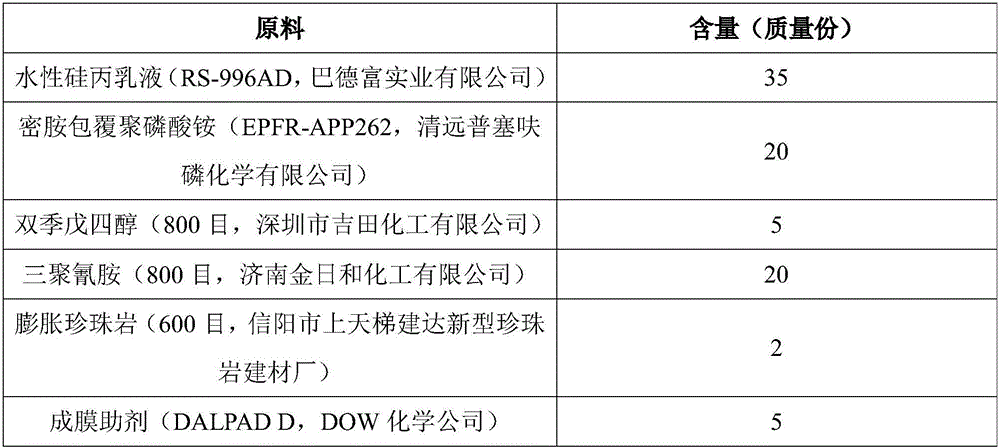

Embodiment 1

[0068] A kind of raw material composition of water-based water-swellable steel structure fireproof coating is as shown in table 1:

[0069] Table 1 A kind of raw material composition list of water-based water-swellable steel structure fireproof coating

[0070]

[0071]

[0072] The preparation process of the water-based water-swellable steel structure fireproof coating of the present embodiment is as follows:

[0073] Weigh each component according to the ratio of raw materials, add water, film-forming aid, wetting and dispersing agent, anti-fungal agent, anti-flash rust agent and pH regulator into the dispersion tank, and stir at a speed of 300r / min for 10 minutes; Add melamine-coated ammonium polyphosphate, dipentaerythritol, melamine and expanded perlite, and disperse at a high speed of 2000r / min for 30 minutes; add water-based silicone acrylic emulsion, defoamer and thickener, and stir for 30 minutes at a speed of 500r / min , and discharged to obtain a water-based wat...

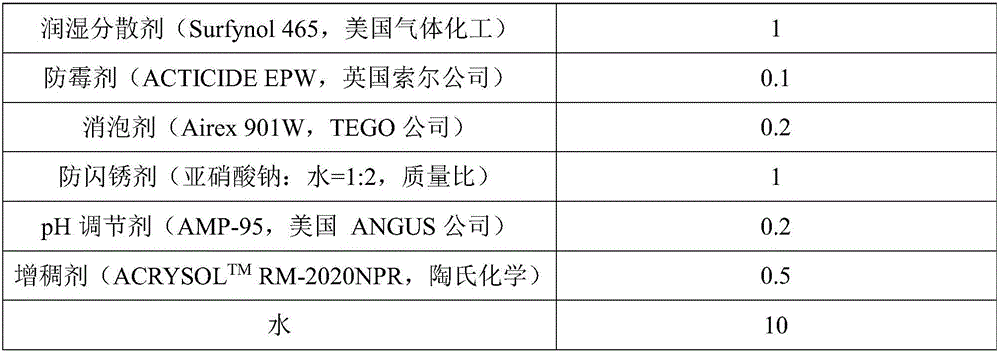

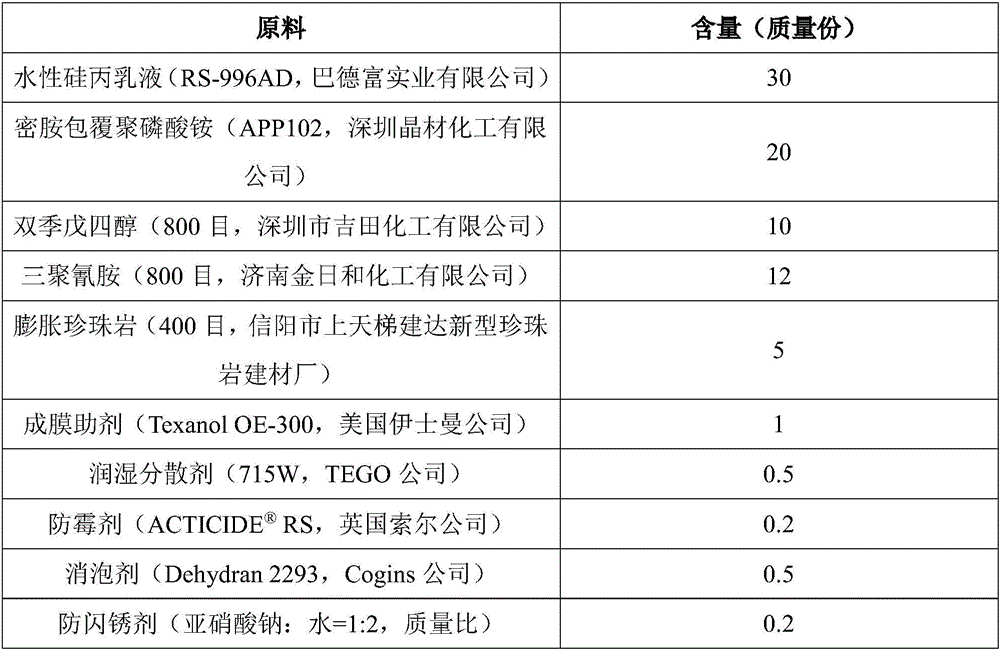

Embodiment 2

[0075] A kind of raw material composition of water-based water-swellable steel structure fireproof coating is as shown in table 2:

[0076] Table 2 A kind of raw material composition table of water-based water-swellable steel structure fireproof coating

[0077]

[0078]

[0079] The preparation process of the water-based water-swellable steel structure fireproof coating of the present embodiment is as follows:

[0080] Weigh each component according to the ratio of raw materials, add water, film-forming aid, wetting and dispersing agent, anti-fungal agent, anti-flash rust agent and pH regulator into the dispersion tank, stir at 800r / min for 5min; add Melamine-coated ammonium polyphosphate, dipentaerythritol, melamine and expanded perlite were dispersed at a high speed of 2000r / min for 40 minutes; water-based silicone acrylic emulsion, defoamer and thickener were added and stirred for 20 minutes at a speed of 1000r / min. The material is discharged to obtain a water-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com