Novel fireproof heat-insulating building material and preparation method thereof

A technology of building materials and building boards, applied in the field of building materials, can solve the problems of high cost, poor fireproof and heat insulation effect, etc., and achieve the effect of low cost, good fireproof and heat insulation effect, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

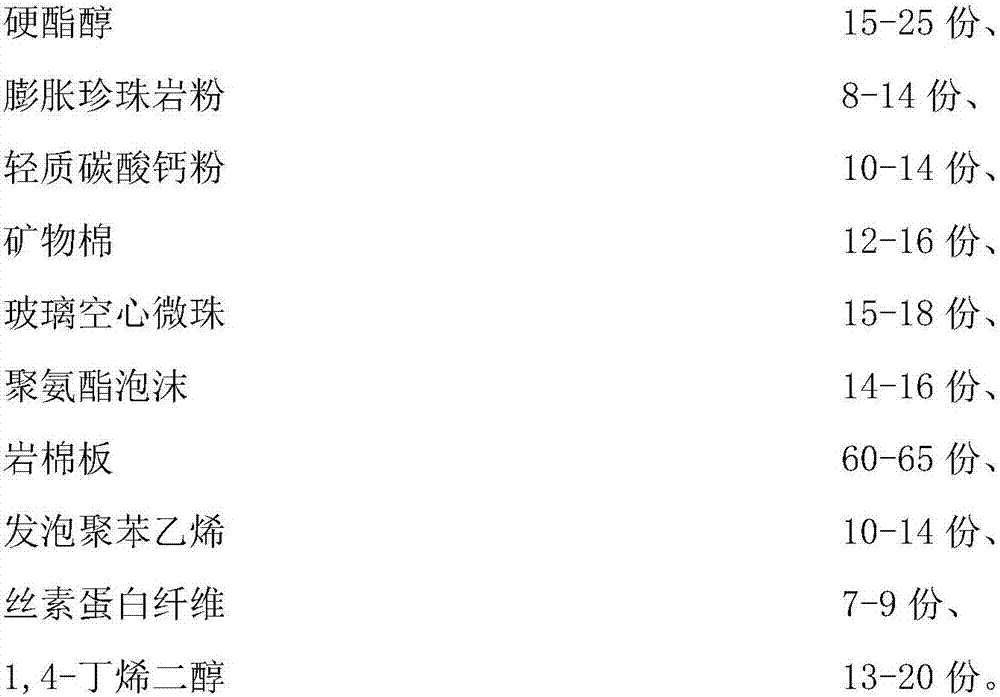

[0040] A novel fire-proof and heat-insulating building material is made of the following raw materials in parts by weight:

[0041]

[0042] It has the advantages of the best fire and heat insulation effect and the lowest cost.

[0043] Slag wool has low bulk density, low thermal conductivity, non-combustibility, heat resistance, frost resistance, corrosion resistance, and strong chemical stability. Using slag wool to make building materials can achieve the purpose of waste reuse.

[0044] A preparation method of a novel fire-proof and heat-insulating building material, comprising the following steps:

[0045] (1) Expanded perlite powder and light calcium carbonate powder are pulverized into 350 mesh powders respectively;

[0046] (2) Take by weight 25 parts of stearyl alcohol, 14 parts of expanded perlite powder, 14 parts of light calcium carbonate powder, 16 parts of mineral wool, 18 parts of glass hollow microspheres, 16 parts of polyurethane foam, rock wool board 65 p...

Embodiment 2

[0052] A novel fire-proof and heat-insulating building material is made of the following raw materials in parts by weight:

[0053]

[0054] It has the advantages of good fireproof and heat insulation effect and low cost.

[0055] Slag wool has low bulk density, low thermal conductivity, non-combustibility, heat resistance, frost resistance, corrosion resistance, and strong chemical stability. Using slag wool to make building materials can achieve the purpose of waste reuse.

[0056] A preparation method of a novel fire-proof and heat-insulating building material, comprising the following steps:

[0057] (1) Expanded perlite powder and light calcium carbonate powder are pulverized into 350 mesh powders respectively;

[0058] (2) Take by weight 20 parts of stearyl alcohol, 10 parts of expanded perlite powder, 12 parts of light calcium carbonate powder, 14 parts of mineral wool, 16 parts of glass hollow microspheres, 15 parts of polyurethane foam, and rock wool board 64 par...

Embodiment 3

[0064] A novel fire-proof and heat-insulating building material is made of the following raw materials in parts by weight:

[0065]

[0066] It has the advantages of good fireproof and heat insulation effect and low cost.

[0067] Slag wool has low bulk density, low thermal conductivity, non-combustibility, heat resistance, frost resistance, corrosion resistance, and strong chemical stability. Using slag wool to make building materials can achieve the purpose of waste reuse.

[0068] A preparation method of a novel fire-proof and heat-insulating building material, comprising the following steps:

[0069] (1) Expanded perlite powder and light calcium carbonate powder are pulverized into 350 mesh powders respectively;

[0070] (2) Take by weight 15 parts of stearyl alcohol, 8 parts of expanded perlite powder, 10 parts of light calcium carbonate powder, 12 parts of mineral wool, 15 parts of glass hollow microspheres, 14 parts of polyurethane foam, rock wool board 60 parts, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com