Steel-wood heat insulation fireproof door and manufacturing method thereof

A fire door, wood technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

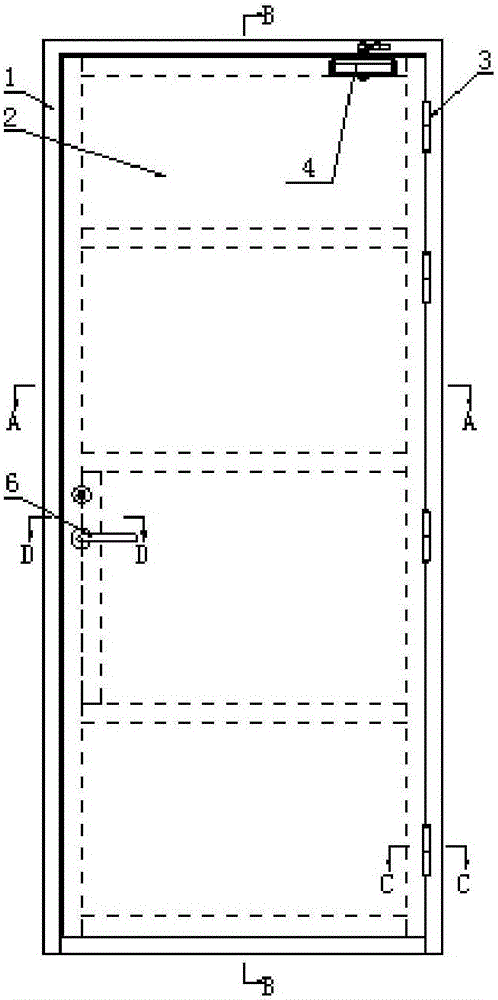

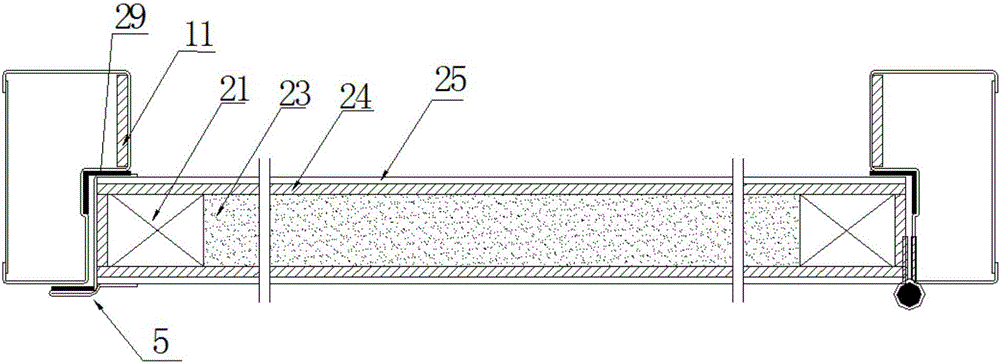

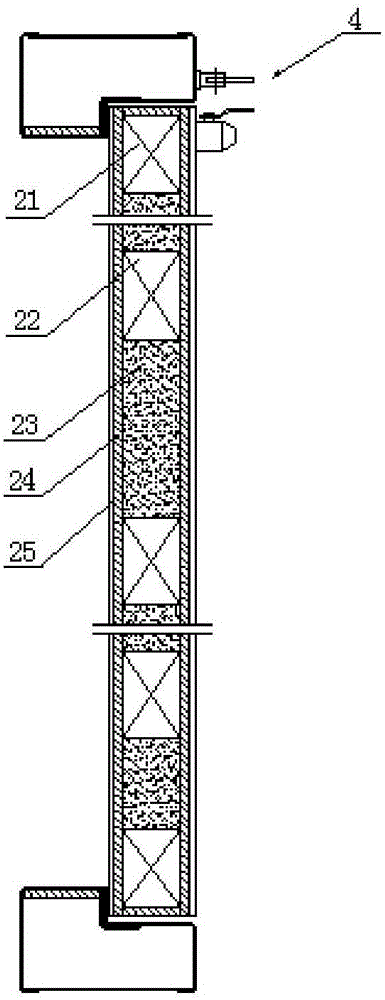

[0044] Such as figure 1 , figure 2 As shown, a steel-wood heat-insulated fire door includes a door frame 1 and a door leaf 2; the door frame 1 is hinged with the door leaf 2 through a fireproof hinge 3; the door leaf 2 includes a frame 21 around the door leaf and an inner frame 22 of the door leaf; The skeleton 22 is divided into a plurality of regions. Expanded perlite fire board 23 is filled in multiple areas to form the door core. A first magnesium-silicon fireproof board 24 is fixed on the surface of the door core, and a flame-retardant plywood 25 is fixed on the surface of the first magnesium-silicon fireproof board 24; the door frame 1 has a door stop line, and the door leaf 2 is limited by the door stop line when it is close...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com