Preparation method of open-fire resistance thermal insulation textile

A technology that is resistant to open fire and textiles, and is used in textiles and papermaking, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

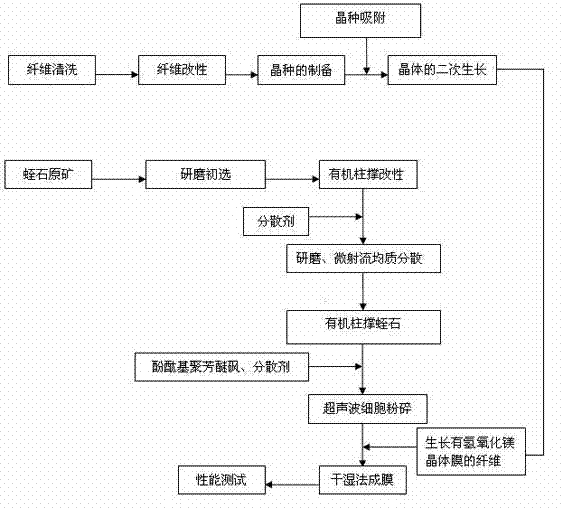

Image

Examples

Embodiment 1

[0025] Embodiment 1: (1) Cotton fabric is cut into the piece of fixed size, removes the grease and the wax on fabric surface with ether. Using citric acid as a modifying reagent and sodium hypophosphite as a catalyst, a modified solution was prepared, wherein the content of citric acid in the modified solution was 9wt% (citric acid: sodium hypophosphite = 3:2), and the cotton fabric Carboxyl modification is carried out by dipping in the modifying solution twice and rolling, and the modified fabric must be placed for more than 12 h to achieve equilibrium.

[0026] (2) Under the condition of 35±0.5 ℃, add 0.1 mol / L dilute NH 3 · h 2 O solution was added dropwise to 200 mL polyvinylpyrrolidone solution (10 g / L) to adjust the pH of the system to 10.0±0.2, and then 0.05 mol / L MgCl was added at a rate of 10 mL / hr 2 The solution was added dropwise to dilute NH 3 · h 2 In the mixed liquid of O solution and polyvinylpyrrolidone, the liquid addition time lasts for 2 h, during whi...

Embodiment 2

[0034] (1) Cut the sulfonamide fabric into blocks of a fixed size, remove the oil agent on the surface of the fabric with ether, and use 7.5g / l sodium hydroxide as a modifying agent to immerse the sulfone fiber fabric in the modifying solution for two Carboxyl modification is carried out by dipping and padding, and the modified fabric must be placed for more than 12 hours to achieve equilibrium.

[0035] (2) Under the condition of 35±0.5 ℃, add 0.1 mol / L dilute NH 3 · h 2 O solution was added dropwise to 200 mL polyvinylpyrrolidone solution (10 g / L) to adjust the pH of the system to 10.0±0.2, and then 0.05 mol / L MgCl was added at a rate of 10 mL / hr 2 The solution was added dropwise to dilute NH 3 · h 2 In the mixed liquid of O solution and polyvinylpyrrolidone, the liquid addition time lasts for 2 h, during which, 0.1mol / L NH 3 · h 2 The pH value of the O solution control system is in the range of 10.0-10.5. After the liquid addition is completed, the reaction solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com