Nano graphene fireproof paint and construction method thereof

A nano-graphene and fire-resistant coating technology, applied in fire-resistant coatings, cement coatings, coatings, etc., can solve the problems of affecting the fire-resistant thermal insulation performance of fire-resistant coatings, insufficient coating strength, poor fire-resistant performance, etc., to improve the fire-resistant insulation The effect of thermal performance, strong bonding and excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Weighing of raw materials: 525# Portland cement 5kg, expanded vermiculite 0.7kg, expanded vitrified beads 1.1kg, expanded perlite 0.8kg, nanographene 0.25kg, fumed silica 1kg, silane coupling Reagent solution (the volume ratio of vinyl triethoxy silane, water and ethanol is 15:8:77) 0.4kg, polyvinyl alcohol emulsion 2.3kg, chlorinated paraffin 1.2kg and water 7kg, ready for use;

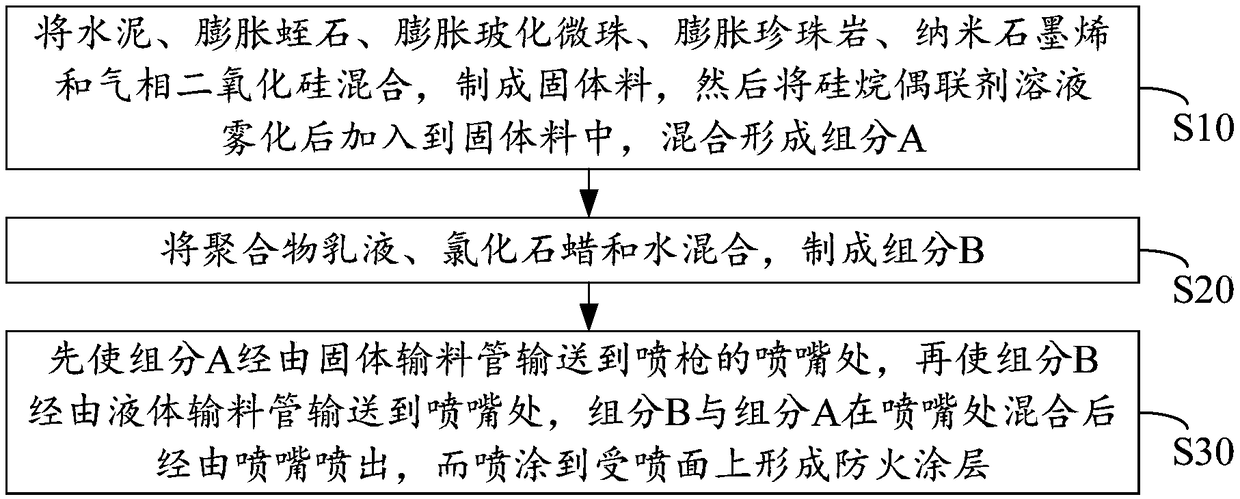

[0041] (2) Mix cement, expanded vermiculite, expanded vitrified beads, expanded perlite, nano graphene and fumed silica to make a solid material, and then atomize the silane coupling agent solution and add it to the solid material , Mixed to form component A;

[0042] (3) Mix polymer emulsion, chlorinated paraffin and water to make component B;

[0043] (4) Component A is first delivered to the nozzle of the spray gun through the solid feed pipe, and then component B is delivered to the nozzle through the liquid feed pipe. Component B and component A are mixed at the nozzle and sprayed through t...

Embodiment 2

[0045] (1) Weighing of raw materials: 525# Portland cement 4.5kg, expanded vermiculite 0.8kg, expanded vitrified beads 1.2kg, expanded perlite 0.9kg, nanographene 0.2kg, fumed silica 0.9kg, silane Coupling agent solution (Vinyltrimethoxysilane, water, methanol volume ratio 15:8:77) 0.5kg, polyacrylate emulsion 2kg, chlorinated paraffin 1.3kg and water 6.5kg, spare;

[0046] (2) Mix cement, expanded vermiculite, expanded vitrified beads, expanded perlite, nano graphene and fumed silica to make a solid material, and then atomize the silane coupling agent solution and add it to the solid material , Mixed to form component A;

[0047] (3) Mix the polymer emulsion, chlorinated paraffin and water to make component B;

[0048] (4) Component A is first delivered to the nozzle of the spray gun through the solid delivery pipe, and then component B is delivered to the nozzle through the liquid delivery pipe. Component B and component A are mixed at the nozzle and sprayed through the nozzle. T...

Embodiment 3

[0050] (1) Weighing of raw materials: 525# Portland cement 5.5kg, expanded vermiculite 0.5kg, expanded vitrified beads 1.0kg, expanded perlite 0.6kg, nanographene 0.3kg, fumed silica 1.1kg, silane Coupling agent solution (the volume ratio of vinyl triethoxy silane, water, ethanol is 20:8:72) 0.3kg, polyvinyl acetate emulsion 2.5kg, chlorinated paraffin 1.0kg and water 7.57kg, spare;

[0051] (2) Mix cement, expanded vermiculite, expanded vitrified beads, expanded perlite, nano graphene and fumed silica to make a solid material, and then atomize the silane coupling agent solution and add it to the solid material , Mixed to form component A;

[0052] (3) Mix the polymer emulsion, chlorinated paraffin and water to make component B;

[0053] (4) Component A is first delivered to the nozzle of the spray gun through the solid delivery pipe, and then component B is delivered to the nozzle through the liquid delivery pipe. Component B and component A are mixed at the nozzle and sprayed thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com