Double-side opening type wooden heat insulation fireproof door

A fire-proof door and wood technology, applied in the field of fire-proof doors, can solve the problems that the impact resistance needs to be improved, the fire-proof performance cannot be achieved, and the strength of the fire-proof door is poor, so as to achieve the daily opening and closing labor saving, improve the fire-proof effect, and have a good sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

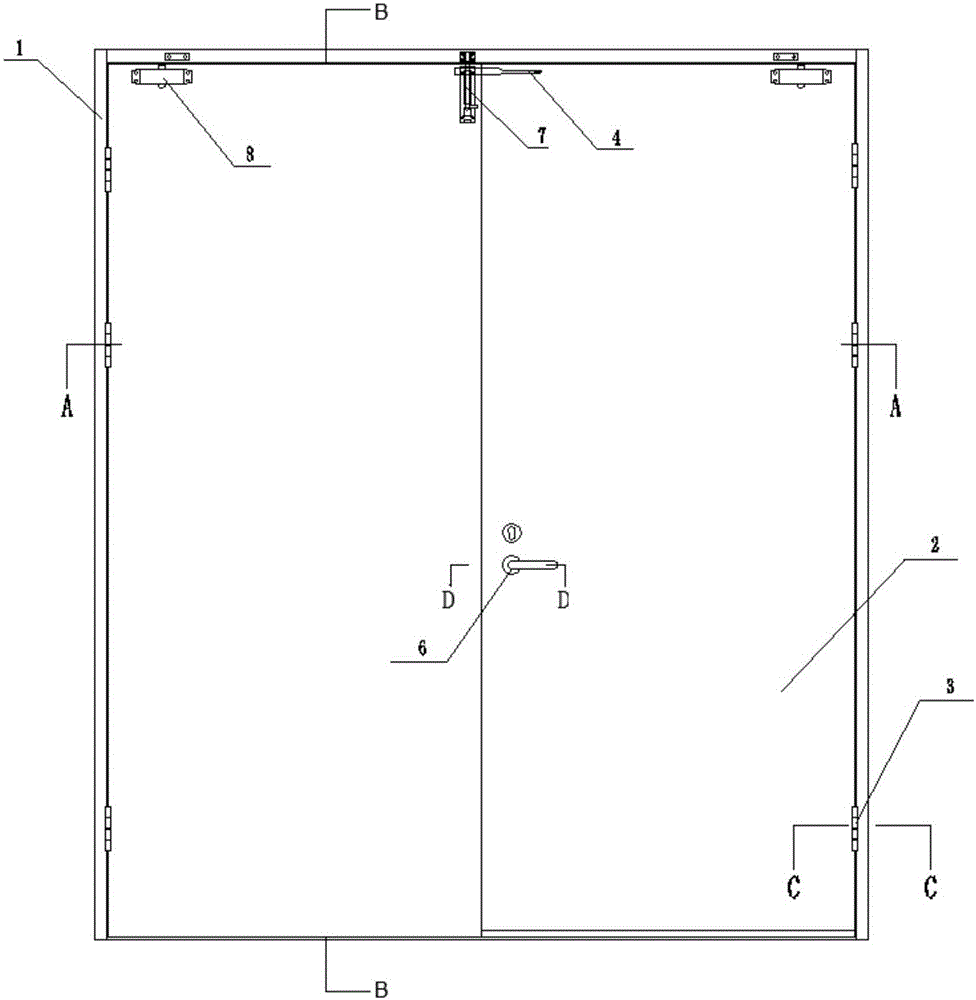

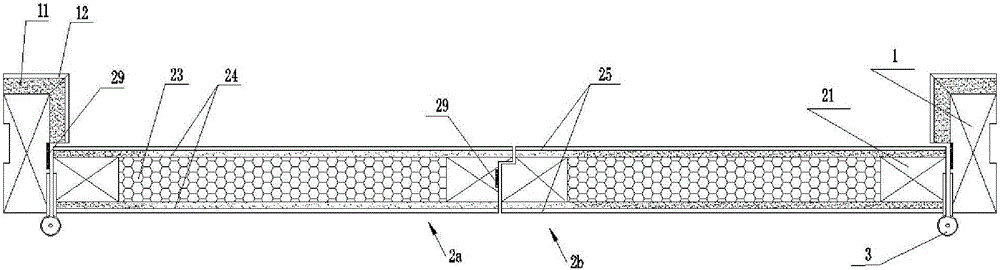

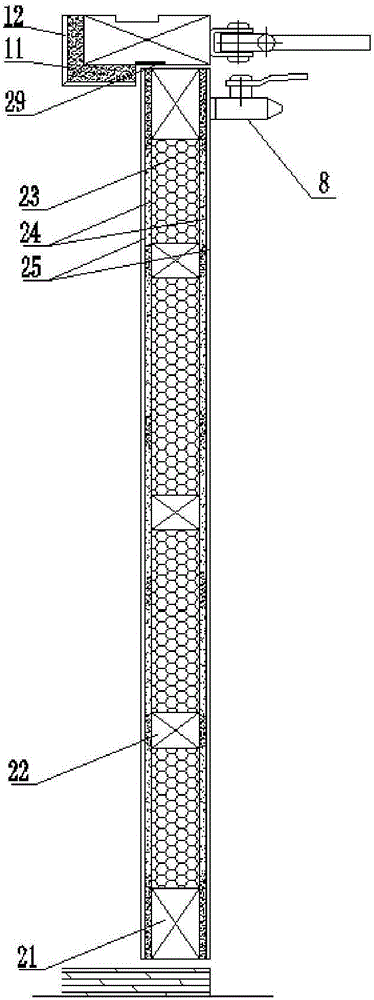

[0032] like figure 1 , figure 2 As shown, a split wooden heat-insulating fire door includes a door frame 1 and two door leaves 2; The structures of the two door leaves 2 are identical. The door leaf 2 includes a framework 21 around the door leaf and an inner framework 22 of the door leaf; the framework 21 around the door leaf is divided into multiple regions by the inner framework 22 of the door leaf. Expanded perlite fireproof boards 23 are filled in multiple areas to form a door core, a first magnesium-silicon fireproof board 24 is fixed on the surface of the door core, and a flame-retardant plywood 25 is fixed on the surface of the first magnesium-silicon fireproof board 24 .

[0033] The door frame 1 has a door stop line, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com