Novel composite perlite board for fire prevention and heat insulation and manufacturing method thereof

A technology of perlite sheet and perlite, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of unreliable burning, large personal injury, long time, etc., and achieve excellent fire protection and heat insulation The effect of good capacity, strength and toughness, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

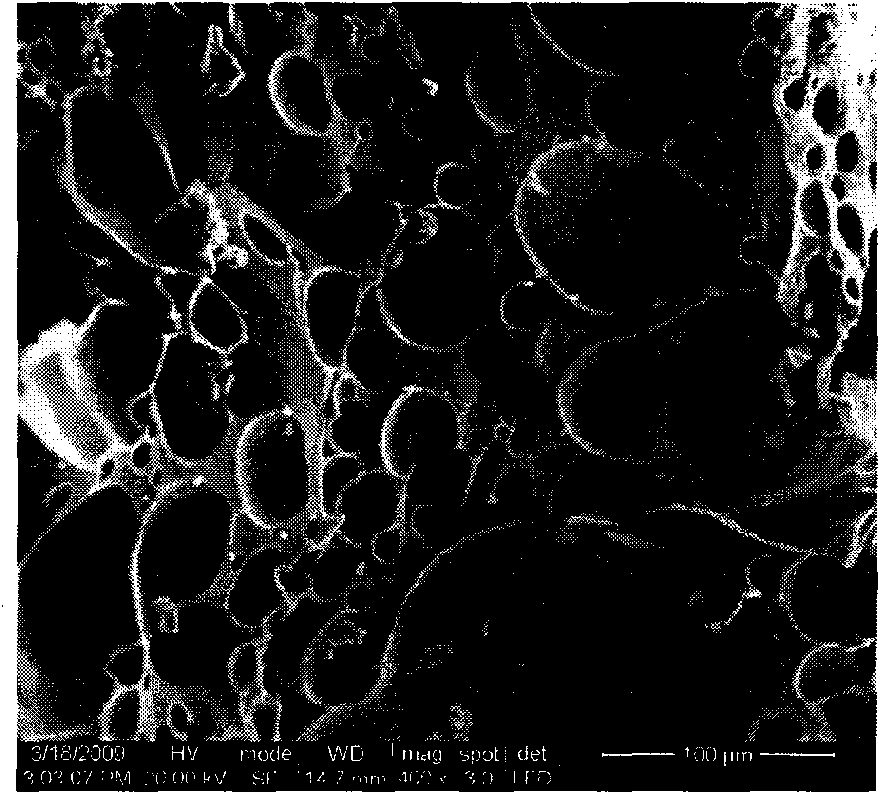

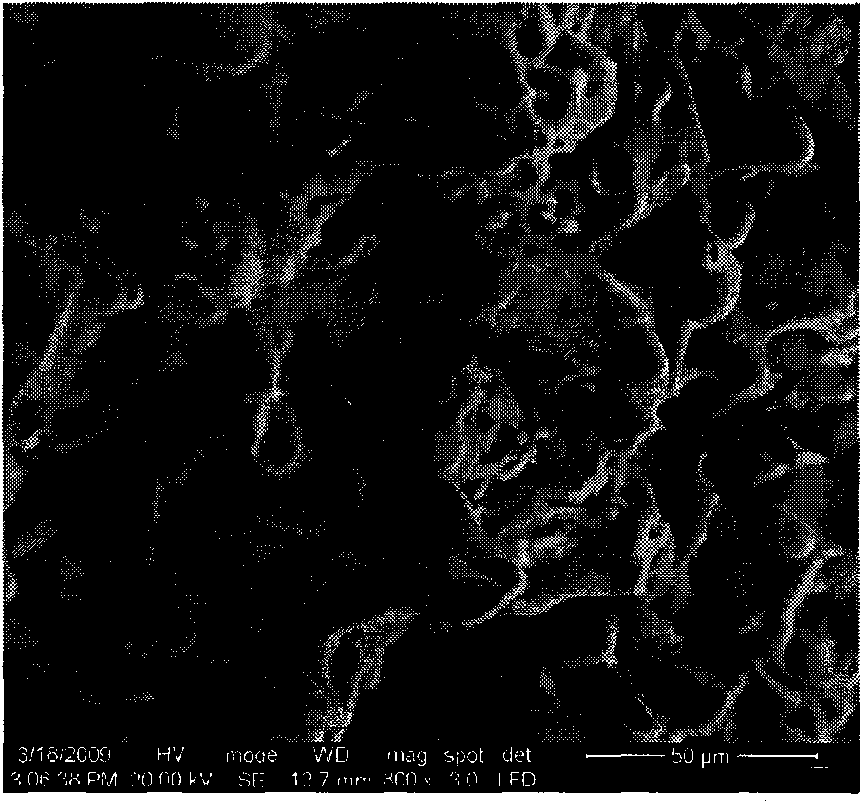

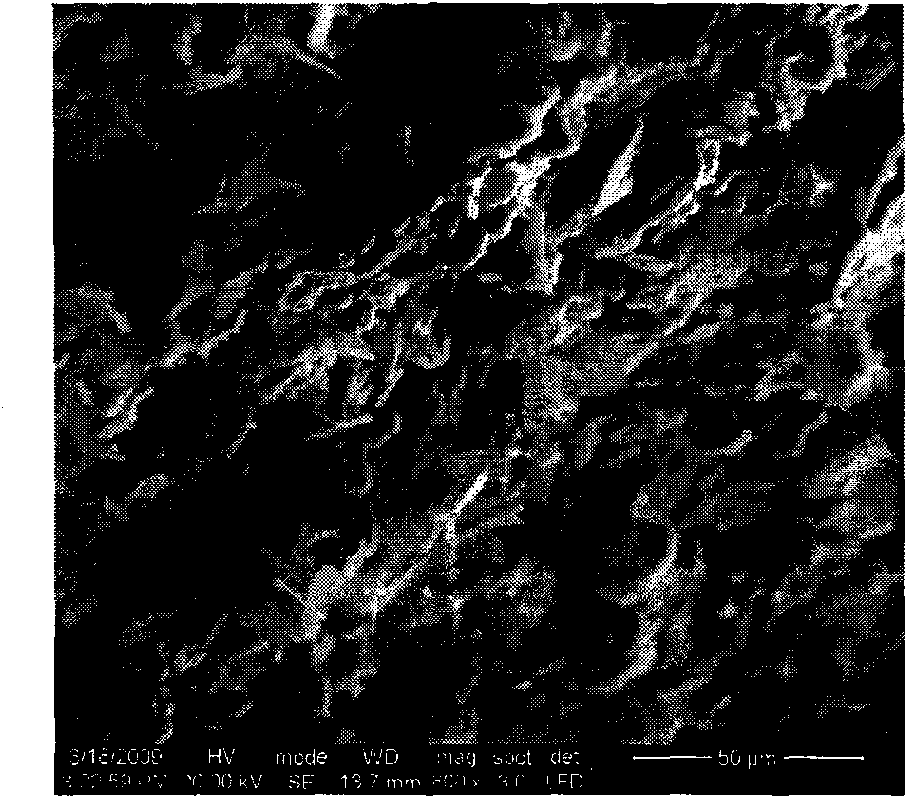

Image

Examples

Embodiment 1

[0023] Embodiment 1: Taking perlite as 100 parts by weight as a benchmark, 50 parts of sodium silicate solution; 4 parts of hydrophobic agent; 8 parts of aluminum hydroxide; 3 parts of calcium carbonate; 7 parts of wollastonite; 6 parts of phosphoric acid; 8 parts of magnesium oxide parts; white carbon black: 1 part; water: 110 parts. After mixing the above materials, put them into the mold at one time and press them into shape, and place the cotton cloth coated with white latex on the upper and lower sides of the materials. After demoulding, obtain a sample with cotton cloth adhered on both sides, put it into an oven to dry, and control the water content within 15%. A porous lightweight product is obtained with a density of 0.28 g / cm 3 , its compressive strength is 0.98MPa; it does not disperse after soaking in water for 10 days, and has a certain waterproof ability. The 42 mm thick composite perlite plate was burned in the flame for 90 minutes, and the highest temperature ...

Embodiment 2

[0024]Embodiment 2: Taking expanded perlite as 100 parts by weight as a benchmark, 60 parts of sodium silicate solution; 5 parts of hydrophobic agent; 7 parts of aluminum hydroxide; 6 parts of calcium carbonate; 12 parts of wollastonite; 4 parts of phosphoric acid; 5 parts; white carbon black: 2 parts; water: 130 parts. After mixing the above materials, put them into the mold at one time and press them into shape, and place the cotton cloth coated with white latex on the upper and lower sides of the materials. After demoulding, obtain a sample with cotton cloth adhered on both sides, put it into an oven to dry, and control the water content within 15%. A porous lightweight product is obtained with a density of 0.33 g / cm 3 , and its compressive strength is 1.05MPa. Soaked in water for 10 days does not disperse, has a certain waterproof ability. The 42 mm thick composite perlite plate was burned in the flame for 90 minutes, and the highest temperature measurement point of the...

Embodiment 3

[0025] Embodiment 3: Taking expanded perlite as 100 parts by weight as a benchmark, 60 parts of sodium silicate solution; 3 parts of hydrophobic agent; 6 parts of aluminum hydroxide; 3 parts of calcium carbonate; 8 parts of wollastonite; 7 parts of phosphoric acid; 7 parts; white carbon black: 2 parts; water: 120 parts. After mixing the above materials, put them into the mold at one time and press them into shape, and place the cotton cloth coated with white latex on the upper and lower sides of the materials. After demoulding, obtain a sample with cotton cloth adhered on both sides, put it into an oven to dry, and control the water content within 15%. A porous lightweight product is obtained with a density of 0.32 g / cm 3 , its compressive strength is 1.05MPa; it does not disperse after soaking in water for 10 days, and has a certain waterproof ability. The 42 mm thick composite perlite plate was burned in the flame for 90 minutes, and the maximum temperature measurement poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com