Expanded organic fireproof blocking material and preparation method thereof

A fire blocking and intumescent technology, which is applied in the field of fire blocking materials and their preparation, can solve problems such as the inability to meet relevant performance requirements, and achieve the effects of improving fire and heat insulation effect, rich raw material sources, and excellent physical and chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The organic fireproof sealing material of the present invention is uniformly kneaded according to the formula in Table 1 (by mass parts) into a plastic solid with certain flexibility, then weighed and packaged.

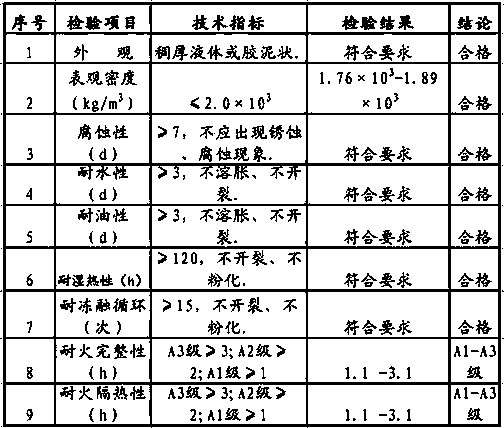

[0035] Raw materials and proportioning (parts by mass), refractory performance of the embodiment of table 1

[0036]

[0037] It can be seen from the above table that the fireproof sealing material is composed of various raw materials. The properties of various raw materials are different, and their own fire resistance performance is quite different. However, they play different roles in the fireproof sealing material and cannot be replaced by each other. Therefore, the raw material ratio of the fireproof plugging material has a significant impact on its fire resistance performance. For the eight examples listed in Table 1, due to the different ratios of raw materials, the fire-resistant time of the fireproof plugging materials shows a large difference, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com