Thermal curing type printless organic silicon pressure-sensitive adhesive tape and preparation method thereof

A technology of silicone pressure-sensitive adhesive and silicon pressure-sensitive tape, which is applied in the direction of adhesives, film/sheet adhesives, coatings, etc., and can solve the problems of corrosion of the attached object, difficulty in dispersing, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

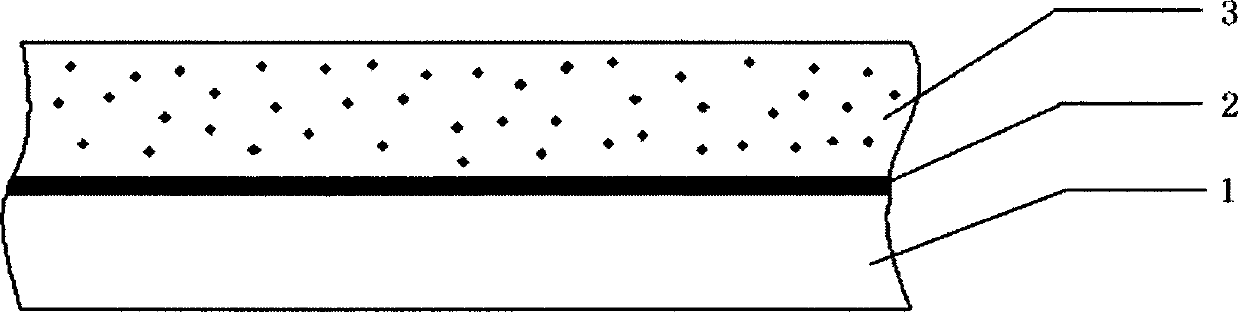

[0040] Such as figure 1 and as figure 2 As shown, a heat-curable non-marking silicone pressure-sensitive adhesive tape includes a base material layer 1 and a silicone pressure-sensitive adhesive layer 3 formed by coating a silicone pressure-sensitive adhesive, on the base material layer 1 and the silicone pressure-sensitive adhesive layer 3 are provided with a primer layer 2 formed by coating a primer; the silicone pressure-sensitive adhesive includes parts by weight of 100 parts of silicone pressure-sensitive adhesive, 30 The toluene of part, the benzoyl peroxide of 0.5 part and shadow remover; Described shadow remover quality accounts for 70% of described benzoyl peroxide quality; Described priming agent comprises the Dow that weight part is 100 parts 7499 primer, 1.4 parts 7367 bridging agent, 0.5 parts 4000 catalyst and 500 parts of toluene. In this technical solution, the image remover is a metal alkoxide or a weak acid salt.

[0041] The present invention also p...

Embodiment 2

[0055] The rest are the same as the above-mentioned embodiments, except that a heat-curable non-marking silicone pressure-sensitive adhesive tape includes a substrate layer 1 and a silicone pressure-sensitive adhesive layer formed by coating a silicone pressure-sensitive adhesive 3. An undercoat layer 2 formed by coating a primer is provided between the substrate layer 1 and the silicone pressure-sensitive adhesive layer 3; the silicone pressure-sensitive adhesive includes parts by weight of 100 parts of silicone pressure-sensitive adhesive, 100 parts of toluene, 3 parts of benzoyl peroxide and a shadow remover; the quality of the shadow remover accounts for 230% of the quality of the benzoyl peroxide; the primer Including 100 parts by weight of Dow 7499 primer, 1.4 parts 7367 bridging agent, 0.5 parts 4000 catalyst and 2000 parts of toluene.

[0056] The present invention also provides a method for making a heat-curing non-marking silicone pressure-sensitive adhesive ta...

Embodiment 3

[0065] The rest are the same as the above-mentioned embodiments, except that a heat-curable non-marking silicone pressure-sensitive adhesive tape includes a substrate layer and a silicone pressure-sensitive adhesive layer formed by coating a silicone pressure-sensitive adhesive, Between the substrate layer and the silicone pressure-sensitive adhesive layer, there is a primer layer formed by coating a primer; the silicone pressure-sensitive adhesive includes 100 parts by weight of silicone pressure-sensitive adhesive. Sensitive glue, 60 parts of toluene, 1.5 parts of benzoyl peroxide and shadow remover; described shadow remover quality accounts for 150% of described benzoyl peroxide quality; described primer includes weight parts and is 100% portion of Dow 7499 primer, 1.4 parts 7367 bridging agent, 0.5 parts 4000 catalyst and 1200 parts of toluene.

[0066] Preferably, the image remover is a metal alkoxide or a weak acid salt.

[0067] The present invention also provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com