Organosilicon conductive adhesive

A technology of conductive adhesive and silicone, which is applied in the direction of conductive adhesives, adhesives, conductive materials dispersed in non-conductive inorganic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

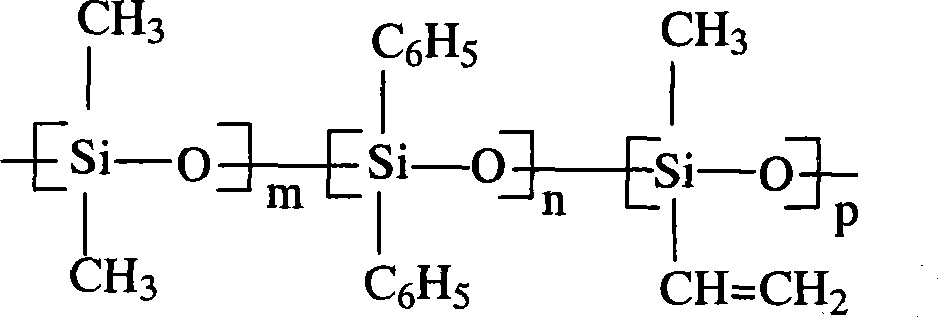

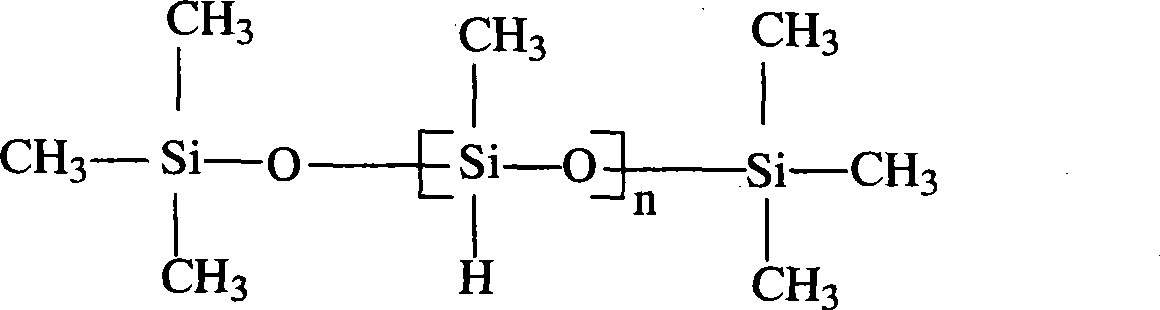

Method used

Image

Examples

Embodiment 1

[0024] Put 50g of vinyl-terminated polydimethylsiloxane, 9g of trimethylsilyl-terminated poly(dimethylsiloxane-co-methylhydrogensiloxane), 20g of methyl styryl silicone , 1g of polymerization inhibitor ethynyl cyclohexanol, 0.1g of polyvinylsiloxane platinum complex catalyst and 5.6g of organic solvent decane were added to the mixer at room temperature, stirred and mixed at a speed of 120 rpm by the stirrer 25min, after mixing evenly, add 325g2-15μm flake silver powder and stir for 15min, then move to the roller gap of 0.1-1mm, the middle roller speed is 88 rpm, the speed ratio of rear roller: middle roller: front roller is 1: On a 3:9 three-roll machine, roll and mix three times continuously to prepare silicone conductive adhesive. The conductive adhesive has a storage period of half a year at 5°C. Heat curing at 160°C, 180°C and 240°C for 1.5 hours respectively. The performance of the product is: small piece thrust 2.5kgf, volume resistivity 2.5×10 -4 Ω·cm, the pencil har...

Embodiment 2

[0026] Except that the ingredient ratio changes to: 65g vinyl-terminated polydimethylsiloxane, 8g trimethylsilyl-terminated poly(dimethylsiloxane-co-methylhydrogensiloxane), 30g methyl Styryl silicone, 0.1g polymerization inhibitor ethynyl cyclohexanol, 0.01g methylvinylsiloxane platinum complex catalyst and organic solvent 10.3g No. 200 mineral spirits (commercially available). After the resin composition and the organic solvent were stirred for 30 minutes, 427 g of flake silver powder was added, and the stirring was continued for 20 minutes. The conductive adhesive was heat-cured at 160°C, 180°C and 240°C for 2 hours respectively, and other operating steps were the same as in Example 1. As a result, the product performance was: small piece thrust 1.5kgf, volume resistivity 4.8×10 -4 Ω·cm, pencil hardness 5.5B.

Embodiment 3

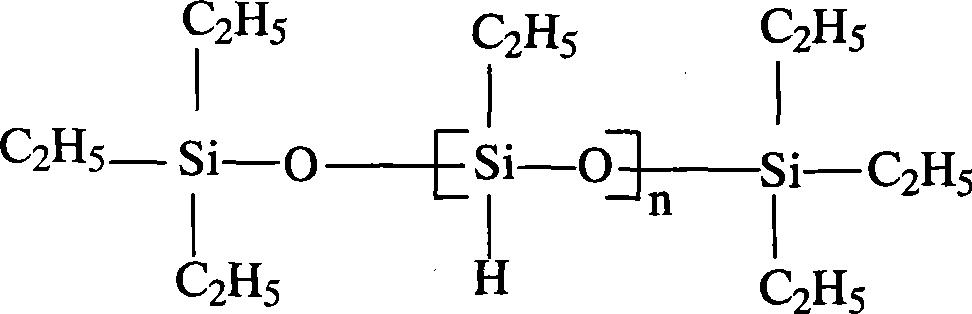

[0028] Except that the ingredient ratio is changed to: 40g vinyl-terminated polydimethylsiloxane, 10g trimethylsilyl-terminated poly(dimethylsiloxane-co-methylhydrogensiloxane), 10g ethyl Hydrogen-containing silicone oil, 2g polymerization inhibitor ethynyl cyclohexanol, 0.2g polyvinylsiloxane platinum complex catalyst and 10g organic solvent decane. After the resin composition and the organic solvent were stirred for 20 minutes, 180 g of flake silver powder was added, and the stirring was continued for 10 minutes. The conductive adhesive was heat-cured at 160°C, 180°C and 240°C for 1 hour respectively, and the other operation steps were the same as in Example 1. As a result, the product performance was: small piece thrust 3.0kgf, volume resistivity 5.6×10 -4 Ω·cm, pencil hardness 5.5B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com