Resin-based flexible ceramic protective coating

A technology of flexible ceramics and protective coatings, applied in the direction of epoxy resin coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of inconvenient coating and brittle paint film, and achieve strong adhesion, low water absorption, and good temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

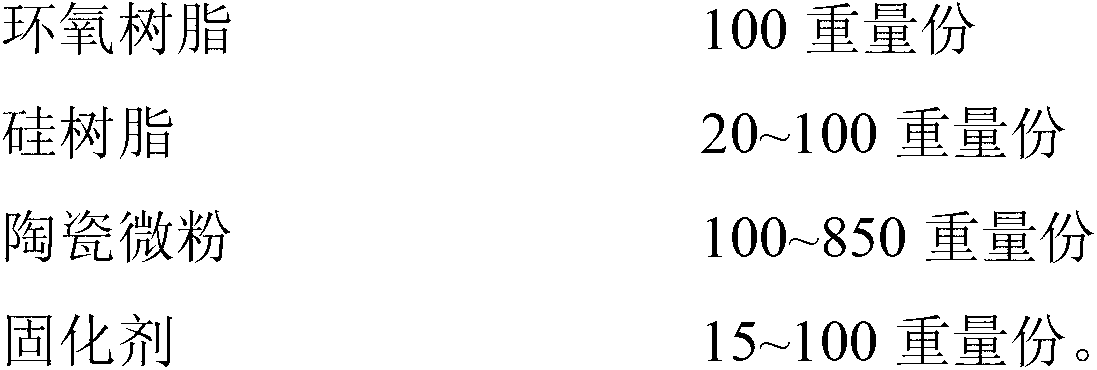

Method used

Image

Examples

Embodiment 1

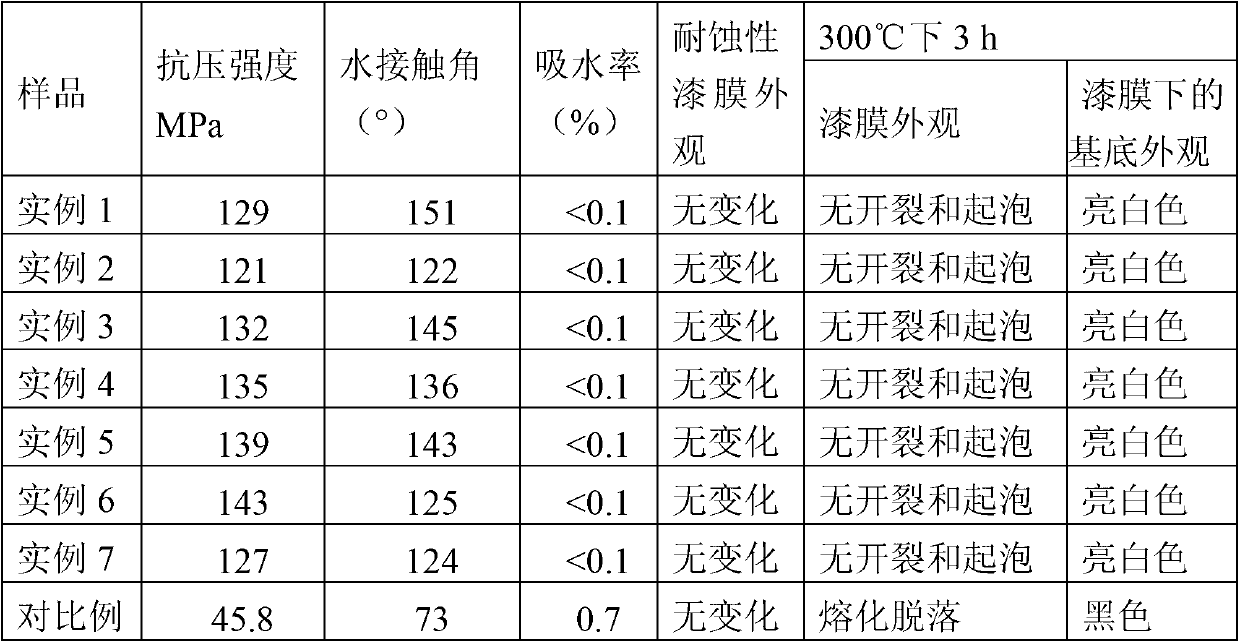

[0030] After mixing 100g of diglycidyl phthalate and 100g of vinylmethyl MQ silicone resin (vinyl content 2.0%, hydroxyl content 1.2%), add 100g of alumina micropowder (average particle size 5μm) and mix at high speed Mix it evenly and make it into component A; then add 30g of isophorone diamine, mix it evenly at 20°C, and then paint or mold it. After standing at 20°C for 3 days, test the corresponding properties of the cured product according to the following method. The test results are listed in Table 1.

[0031] The compressive strength is made into a 20*20*20 cube test block and tested with reference to the national standard GB / T17671-1999.

[0032] The water contact angle is tested with a water contact angle meter after solidification into a film on a small glass piece.

[0033] Water absorption is the weight percentage of the weight gain of the original paint film measured after the paint film is completely immersed in water at 20°C for 3 days.

[0034] The corrosion ...

Embodiment 2

[0037] After mixing 90g of hydrogenated bisphenol A epoxy resin, 10g of bisphenol A epoxy resin E-51 and 20g of vinylmethyl MQ silicone resin (vinyl content 1.2%, hydroxyl content 1.6%), add 300g of silica powder (average particle size is 50μm) and 60g zirconia micropowder (average particle size is 5μm), grind and disperse evenly to form component A; then mix 15g triethylenetetramine and 5g2,4,6-tris(dimethylaminomethyl Base) After phenol is mixed evenly, mix evenly with component A, paint or mold immediately, and test the corresponding properties of the cured product after standing at 25°C for 3 days. The test results are listed in Table 1.

Embodiment 3

[0039] (1) Preparation of silane-modified methyl MQ silicone resin

[0040] Mix 50g toluene, 80g vinylmethyl MQ silicone resin (1.2% vinyl content, 1.6% hydroxyl content), 20g dodecafluoroheptylpropyltrimethoxysilane and 0.3g stannous octoate, and heat up to Reflux at 80°C for 6 hours, and then distill off the solvent toluene under reduced pressure to obtain 100 g of silane-modified methyl MQ silicone resin (hydroxyl content 0.15%).

[0041] (2) Preparation of paint

[0042] Add 100g diglycidyl tetrahydrophthalate to the above 100g silane-modified methyl MQ silicone resin and mix well, then add 100g calcium oxide (average particle size is 10μm), 300g mullite powder (aluminum silicate, The average particle size is 2μm), and grind evenly to form component A; then add 50g of N-aminoethylpiperazine and mix well at room temperature at 25°C, then paint or pour the mold, place it for 30min, then raise the temperature to 80°C and keep it for 6h. After cooling, test the corresponding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com